Graphite coating offers a thin layer of graphite applied to surfaces for enhanced lubrication and reduced friction, ideal for protecting metal parts from wear. Graphite lining involves embedding graphite material within a structure, providing more robust, long-lasting lubrication and heat resistance, often used in industrial applications. Choosing between coating and lining depends on the desired durability, application environment, and maintenance requirements.

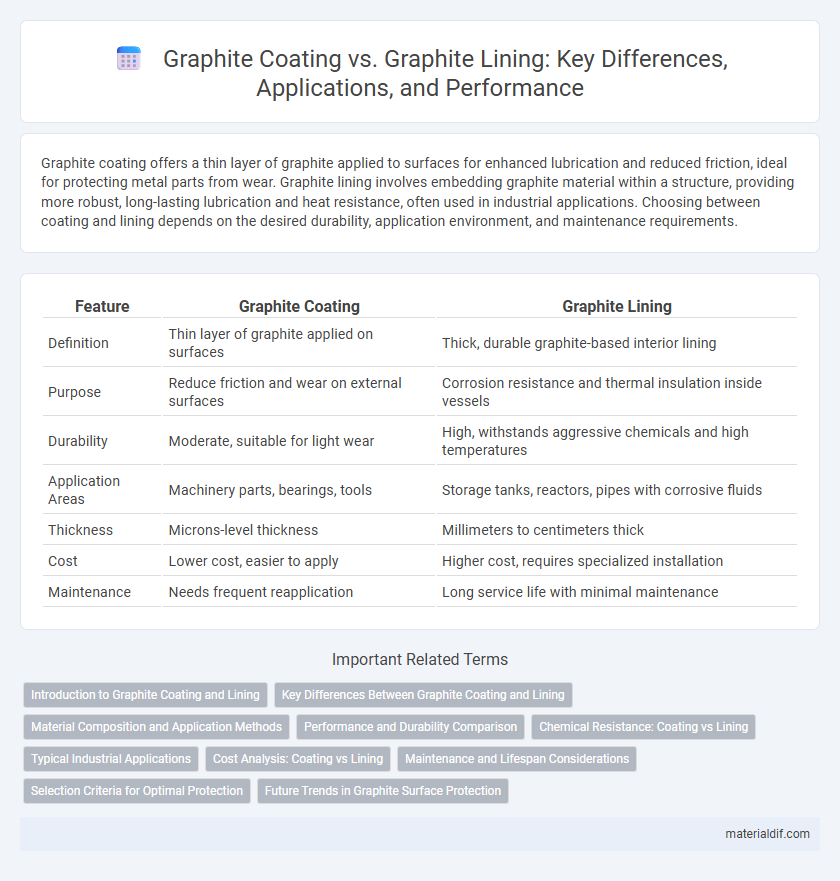

Table of Comparison

| Feature | Graphite Coating | Graphite Lining |

|---|---|---|

| Definition | Thin layer of graphite applied on surfaces | Thick, durable graphite-based interior lining |

| Purpose | Reduce friction and wear on external surfaces | Corrosion resistance and thermal insulation inside vessels |

| Durability | Moderate, suitable for light wear | High, withstands aggressive chemicals and high temperatures |

| Application Areas | Machinery parts, bearings, tools | Storage tanks, reactors, pipes with corrosive fluids |

| Thickness | Microns-level thickness | Millimeters to centimeters thick |

| Cost | Lower cost, easier to apply | Higher cost, requires specialized installation |

| Maintenance | Needs frequent reapplication | Long service life with minimal maintenance |

Introduction to Graphite Coating and Lining

Graphite coating involves applying a thin layer of graphite material onto surfaces to enhance lubricity and corrosion resistance, commonly used in industrial machinery and automotive parts. Graphite lining, by contrast, refers to embedding a graphite layer within equipment such as pipes or reactors to provide superior thermal conductivity and chemical inertness under extreme conditions. Both graphite coating and lining leverage the unique properties of graphite, including high temperature stability and low friction, but are selected based on specific application requirements and environmental factors.

Key Differences Between Graphite Coating and Lining

Graphite coating involves applying a thin layer of graphite material onto a surface to improve lubrication and reduce friction, while graphite lining refers to embedding graphite into a substrate or lining the internal surface of equipment for enhanced wear resistance and thermal stability. Coatings typically offer a thinner, more flexible protective film suitable for moving parts, whereas linings provide a thicker, more robust barrier ideal for high-temperature and corrosive environments. Key differences include the application thickness, durability under mechanical stress, and suitability for specific industrial processes such as heat exchangers or reactor vessels.

Material Composition and Application Methods

Graphite coating typically involves a thin layer of graphite applied through spraying or dipping methods to enhance surface lubricity and corrosion resistance, predominantly using fine graphite powder mixed with binders. In contrast, graphite lining consists of thicker, molded or extruded graphite sheets or blocks bonded to substrates, providing superior thermal conductivity and chemical durability for heavy-duty industrial equipment. Material composition for coatings emphasizes flexibility and adhesion, while linings prioritize structural integrity and high-purity graphite content to withstand extreme operating conditions.

Performance and Durability Comparison

Graphite coating offers enhanced surface hardness and corrosion resistance, significantly improving wear performance in industrial applications. In contrast, graphite lining provides superior chemical inertness and thermal stability, making it ideal for environments with aggressive chemicals or extreme temperatures. Durability in coatings generally depends on adhesion strength and thickness, while linings excel in prolonged exposure resistance and mechanical integrity under stress.

Chemical Resistance: Coating vs Lining

Graphite coating provides a smooth, chemically resistant surface that protects substrates from acidic and corrosive environments, typically used for external applications where chemical exposure is occasional. Graphite lining offers superior chemical resistance by creating a seamless, multi-layer barrier ideal for internal surfaces in aggressive chemical processing, ensuring long-term durability against strong acids, alkalis, and solvents. The choice between graphite coating and lining depends on the level of chemical exposure, with lining preferred for high-resistance industrial applications and coating suited for moderate protection.

Typical Industrial Applications

Graphite coatings are commonly used in high-temperature industrial applications such as steel manufacturing, where they provide corrosion resistance and thermal stability on metal surfaces. Graphite linings are primarily applied in chemical processing tanks and reactors to protect against acidic and abrasive environments by creating a wear-resistant barrier. Both methods enhance equipment lifespan but are selected based on whether surface protection or internal lining durability is required.

Cost Analysis: Coating vs Lining

Graphite coating generally involves a thinner application layer that reduces material costs and requires less downtime for installation, making it a more economical choice for budget-sensitive projects. Graphite lining, with its thicker, more durable composition, incurs higher upfront expenses due to increased material usage and labor intensity but offers superior longevity and wear resistance, leading to lower maintenance costs over time. Evaluating total cost of ownership reveals that graphite coating minimizes initial capital outlay, while graphite lining provides better long-term value through extended service life and reduced replacement frequency.

Maintenance and Lifespan Considerations

Graphite coating offers a smooth, wear-resistant surface that requires minimal maintenance and extends equipment lifespan by preventing corrosion and abrasion. Graphite lining, on the other hand, provides a thicker protective barrier ideal for high-impact or highly corrosive environments but demands more frequent inspections and occasional re-lining to maintain performance. Selecting between coating and lining depends on operational conditions, balancing maintenance intervals with durability requirements for optimal cost-efficiency.

Selection Criteria for Optimal Protection

Graphite coating provides a thin, uniform layer that offers excellent corrosion resistance and thermal conductivity, making it ideal for surfaces requiring smooth finishes and heat transfer efficiency. In contrast, graphite lining delivers a thick, robust barrier that excels in chemical inertness and abrasion resistance, suitable for harsh environments involving aggressive chemicals or abrasive materials. Selection criteria should prioritize operational conditions such as temperature ranges, chemical exposure, mechanical wear, and desired lifespan to determine the appropriate graphite protection method.

Future Trends in Graphite Surface Protection

Graphite coating offers enhanced corrosion resistance and thermal conductivity, making it a preferred choice for advanced industrial applications, while graphite lining excels in abrasion resistance and chemical inertness for heavy-duty containment systems. Emerging trends indicate increased integration of nano-graphite materials and hybrid composites to optimize durability and performance in extreme environments. Future innovations focus on sustainable manufacturing processes and multifunctional coatings that combine conductive and protective properties to meet evolving industrial demands.

Graphite Coating vs Graphite Lining Infographic

materialdif.com

materialdif.com