Expandable graphite features a layered, flake-like structure that allows it to expand significantly when heated, making it ideal for thermal management and fire retardant applications. Spherical graphite, with its smooth, round particles, offers superior conductivity and lubrication properties, enhancing battery performance and industrial uses. Choosing between expandable and spherical graphite depends on the specific requirements for expansion capability, electrical conductivity, and mechanical stability.

Table of Comparison

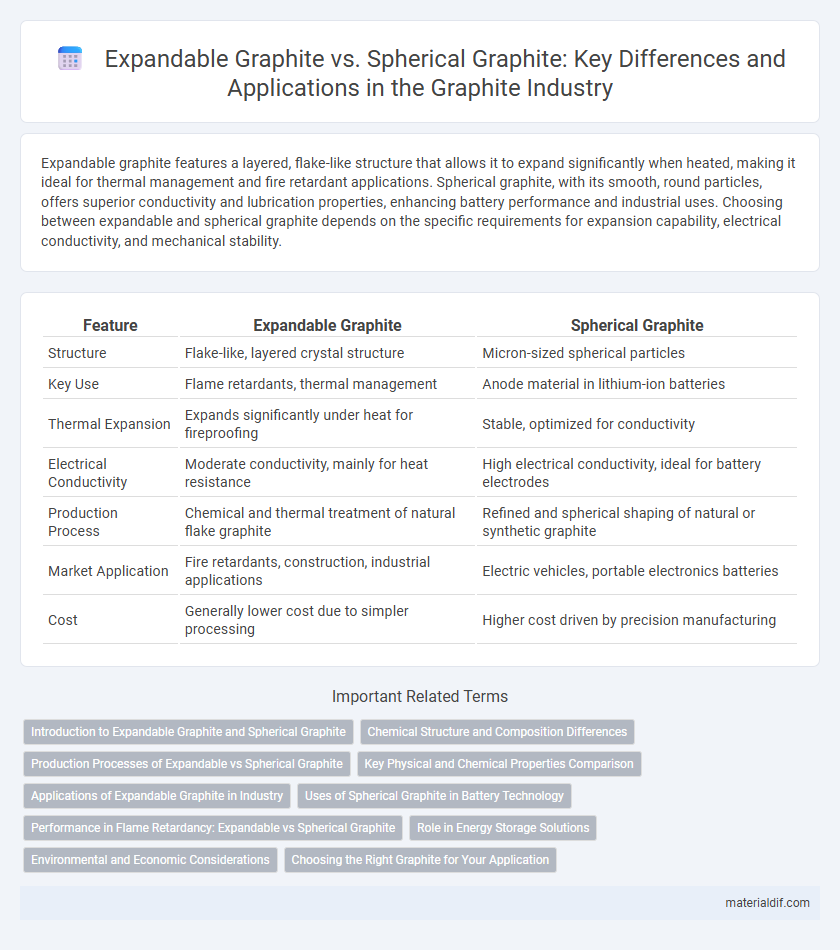

| Feature | Expandable Graphite | Spherical Graphite |

|---|---|---|

| Structure | Flake-like, layered crystal structure | Micron-sized spherical particles |

| Key Use | Flame retardants, thermal management | Anode material in lithium-ion batteries |

| Thermal Expansion | Expands significantly under heat for fireproofing | Stable, optimized for conductivity |

| Electrical Conductivity | Moderate conductivity, mainly for heat resistance | High electrical conductivity, ideal for battery electrodes |

| Production Process | Chemical and thermal treatment of natural flake graphite | Refined and spherical shaping of natural or synthetic graphite |

| Market Application | Fire retardants, construction, industrial applications | Electric vehicles, portable electronics batteries |

| Cost | Generally lower cost due to simpler processing | Higher cost driven by precision manufacturing |

Introduction to Expandable Graphite and Spherical Graphite

Expandable graphite is a form of graphite treated with acids to increase its volume and surface area, making it suitable for applications like flame retardants and thermal management. Spherical graphite consists of natural or synthetic graphite particles that are rounded to enhance packing density and conductivity, primarily used in lithium-ion battery anodes. Both forms offer unique structural properties that cater to different industrial demands, with expandable graphite emphasizing expandability and thermal protection, and spherical graphite focusing on energy storage efficiency.

Chemical Structure and Composition Differences

Expandable graphite consists of layered graphite flakes treated with acids that insert oxidizing agents between layers, causing expansion upon heating due to intercalated compounds such as sulfuric acid. Spherical graphite features graphitic carbon atoms arranged in a roughly spherical morphology, maintaining a more uniform crystalline structure without intercalation agents, resulting in higher purity carbon content. The chemical composition of expandable graphite includes oxidized functional groups and intercalants impacting its properties, whereas spherical graphite has fewer defects and minimal non-carbon elements, enhancing its conductivity and stability.

Production Processes of Expandable vs Spherical Graphite

Expandable graphite is produced through the intercalation of graphite flakes with acids, followed by rapid heating that causes the flakes to expand and form a worm-like structure. Spherical graphite is manufactured by milling natural or synthetic flake graphite into fine particles, then rounding these particles via mechanical or thermal spheroidization processes to create uniform, spherical shapes. The key difference lies in expandable graphite's chemical expansion process versus spherical graphite's physical rounding technique, impacting their respective applications in thermal management and lithium-ion batteries.

Key Physical and Chemical Properties Comparison

Expandable graphite features a layered, flaky structure that enables significant thermal expansion, making it ideal for fire retardants and thermal management applications. Spherical graphite consists of rounded particles with high purity and excellent electrical conductivity, commonly used in lithium-ion battery anodes. The key physical differences include particle shape and surface area, while chemically, both share high carbon content but differ in oxidation behavior and intercalation capacity.

Applications of Expandable Graphite in Industry

Expandable graphite is widely utilized in industries such as fire protection, electronics, and battery manufacturing due to its excellent thermal stability and flame retardant properties. It serves as a key material in intumescent coatings, gaskets, and seals, providing effective fire resistance and thermal insulation. Its ability to expand and form a protective char layer under heat makes it indispensable in construction and automotive applications for enhancing safety and durability.

Uses of Spherical Graphite in Battery Technology

Spherical graphite plays a critical role in lithium-ion battery technology as an anode material due to its high purity, excellent conductivity, and uniform particle size, which enhance battery performance and cycle life. Its spherical morphology improves electrode packing density and enables efficient lithium-ion intercalation, resulting in higher energy density and faster charge-discharge rates. Compared to expandable graphite, spherical graphite offers superior stability and electrochemical properties essential for advanced electric vehicle and portable electronics batteries.

Performance in Flame Retardancy: Expandable vs Spherical Graphite

Expandable graphite exhibits superior flame retardancy due to its ability to expand upon heating, forming an insulating char layer that effectively slows down heat and mass transfer. Spherical graphite, while beneficial for electrical conductivity and lubrication, lacks this intumescent property, resulting in lower flame retardant performance. The expandable form's expansion ratio and graphitic structure critically enhance thermal stability and fire resistance in polymer composites.

Role in Energy Storage Solutions

Expandable graphite offers superior thermal stability and expansion properties, making it ideal for enhancing the safety and efficiency of battery separators in energy storage systems. Spherical graphite provides excellent electrical conductivity and structural integrity, serving as a highly effective anode material in lithium-ion batteries. Both forms play crucial roles in optimizing energy density and durability, with expandable graphite improving thermal management and spherical graphite boosting electrochemical performance.

Environmental and Economic Considerations

Expandable graphite offers significant environmental benefits due to its lower energy consumption during production compared to spherical graphite, which requires intensive processing. Economically, expandable graphite is more cost-effective, making it suitable for large-scale industrial applications where budget and sustainability are priorities. Spherical graphite, while more energy-intensive and expensive, provides higher purity and performance for advanced battery and electronic applications, justifying its cost in specialized markets.

Choosing the Right Graphite for Your Application

Expandable graphite offers excellent thermal stability and flame-retardant properties, making it ideal for applications requiring fire protection and thermal insulation. Spherical graphite, known for its high electrical conductivity and superior energy density, is preferred in lithium-ion battery anode materials and energy storage solutions. Selecting the right graphite depends on application-specific needs such as thermal conductivity, electrical performance, and mechanical stability.

Expandable Graphite vs Spherical Graphite Infographic

materialdif.com

materialdif.com