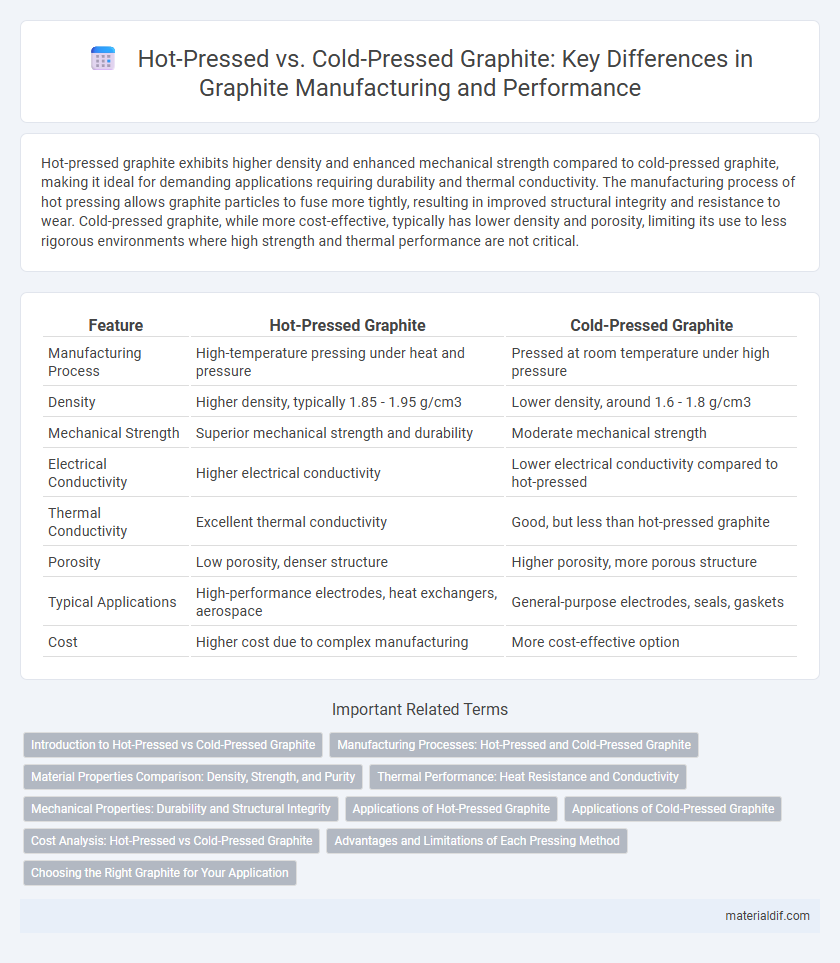

Hot-pressed graphite exhibits higher density and enhanced mechanical strength compared to cold-pressed graphite, making it ideal for demanding applications requiring durability and thermal conductivity. The manufacturing process of hot pressing allows graphite particles to fuse more tightly, resulting in improved structural integrity and resistance to wear. Cold-pressed graphite, while more cost-effective, typically has lower density and porosity, limiting its use to less rigorous environments where high strength and thermal performance are not critical.

Table of Comparison

| Feature | Hot-Pressed Graphite | Cold-Pressed Graphite |

|---|---|---|

| Manufacturing Process | High-temperature pressing under heat and pressure | Pressed at room temperature under high pressure |

| Density | Higher density, typically 1.85 - 1.95 g/cm3 | Lower density, around 1.6 - 1.8 g/cm3 |

| Mechanical Strength | Superior mechanical strength and durability | Moderate mechanical strength |

| Electrical Conductivity | Higher electrical conductivity | Lower electrical conductivity compared to hot-pressed |

| Thermal Conductivity | Excellent thermal conductivity | Good, but less than hot-pressed graphite |

| Porosity | Low porosity, denser structure | Higher porosity, more porous structure |

| Typical Applications | High-performance electrodes, heat exchangers, aerospace | General-purpose electrodes, seals, gaskets |

| Cost | Higher cost due to complex manufacturing | More cost-effective option |

Introduction to Hot-Pressed vs Cold-Pressed Graphite

Hot-pressed graphite exhibits superior density, thermal conductivity, and mechanical strength compared to cold-pressed graphite due to its higher manufacturing pressure and temperature. Cold-pressed graphite, produced at lower pressures and temperatures, typically features increased porosity and lower thermal performance, making it suitable for less demanding applications. Understanding the distinctions in production techniques directly impacts the selection of graphite materials for high-performance industrial uses.

Manufacturing Processes: Hot-Pressed and Cold-Pressed Graphite

Hot-pressed graphite is manufactured by applying simultaneous high temperature and pressure, resulting in a dense, uniform microstructure with enhanced mechanical strength and thermal conductivity. Cold-pressed graphite is produced by compressing graphite powder at room temperature, leading to lower density and porosity but offering cost-effective production and adequate conductivity for less demanding applications. The hot-pressing process typically yields superior structural integrity, making it suitable for high-performance industrial uses, while cold-pressed graphite is preferred for its economic advantages in mass production.

Material Properties Comparison: Density, Strength, and Purity

Hot-pressed graphite exhibits higher density and strength compared to cold-pressed graphite, due to the increased pressure applied during manufacturing, resulting in a more compact and robust microstructure. Purity levels in hot-pressed graphite are also generally superior, minimizing impurities and enhancing electrical conductivity and thermal stability. Cold-pressed graphite, while less dense and strong, may retain slightly more porosity and lower purity, which can affect its mechanical performance and durability in high-temperature applications.

Thermal Performance: Heat Resistance and Conductivity

Hot-Pressed Graphite demonstrates superior thermal performance compared to Cold-Pressed Graphite due to its higher density and enhanced crystalline structure, resulting in excellent heat resistance and thermal conductivity. Its uniform pore distribution minimizes thermal resistance, making it ideal for high-temperature applications requiring efficient heat dissipation. Cold-Pressed Graphite, with lower density and higher porosity, exhibits comparatively reduced thermal conductivity and heat resistance.

Mechanical Properties: Durability and Structural Integrity

Hot-Pressed Graphite exhibits superior mechanical properties compared to Cold-Pressed Graphite due to its higher density and uniform microstructure, resulting in enhanced durability and structural integrity. The hot-pressing process reduces porosity, increasing compressive strength and resistance to thermal shock, which is critical for high-performance applications. In contrast, Cold-Pressed Graphite typically shows lower mechanical strength and increased brittleness, limiting its effectiveness in demanding environments.

Applications of Hot-Pressed Graphite

Hot-pressed graphite exhibits superior density, strength, and thermal conductivity compared to cold-pressed graphite, making it ideal for high-performance heat exchangers, electromagnetic shielding, and battery anode materials. Its enhanced durability supports aerospace and semiconductor manufacturing industries where precision and reliability are critical. The improved microstructure of hot-pressed graphite enables efficient thermal management in electric vehicle components and fuel cells.

Applications of Cold-Pressed Graphite

Cold-pressed graphite is widely utilized in applications requiring high thermal conductivity and excellent electrical performance, such as in battery electrodes, fuel cells, and heat exchangers. Its porous structure offers superior compressibility and flexibility, making it ideal for gasketing, seals, and thermal insulation components in industrial machinery. This material also supports chemical resistance and durability in demanding environments, extending its use in automotive and aerospace industries.

Cost Analysis: Hot-Pressed vs Cold-Pressed Graphite

Hot-pressed graphite typically incurs higher manufacturing costs due to the elevated pressure and temperature requirements that enhance material density and conductivity. Cold-pressed graphite, while less expensive to produce, generally exhibits lower mechanical strength and electrical performance, influencing its application scope. Cost analysis reveals that choosing hot-pressed graphite is justified for high-performance needs despite premium pricing, whereas cold-pressed graphite suits budget-sensitive projects with moderate performance demands.

Advantages and Limitations of Each Pressing Method

Hot-pressed graphite exhibits superior density, enhanced mechanical strength, and improved thermal conductivity due to the application of heat and pressure during manufacturing, making it ideal for high-temperature and high-wear applications. Cold-pressed graphite, produced without heat, generally displays lower density and strength but benefits from lower production costs and better electrical conductivity, suitable for less demanding environments. Limitations of hot-pressed graphite include higher manufacturing complexity and cost, while cold-pressed graphite may suffer from porosity and reduced durability under extreme conditions.

Choosing the Right Graphite for Your Application

Hot-pressed graphite offers superior density, thermal conductivity, and mechanical strength compared to cold-pressed graphite, making it ideal for high-temperature and high-stress applications such as semiconductor manufacturing and aerospace components. Cold-pressed graphite is more porous and less dense but provides cost-effective solutions for applications requiring good electrical conductivity and moderate thermal performance, like battery anodes or electrodes. Selecting the right graphite depends on balancing performance requirements with budget constraints and environmental factors specific to the intended use.

Hot-Pressed Graphite vs Cold-Pressed Graphite Infographic

materialdif.com

materialdif.com