Flexible graphite offers superior adaptability for sealing applications, conforming easily to uneven surfaces and complex shapes, whereas rigid graphite provides enhanced structural strength and stability in high-pressure environments. The choice between flexible and rigid graphite depends on the specific requirements of temperature resistance, mechanical durability, and sealing effectiveness. Flexible graphite excels in dynamic conditions, while rigid graphite is preferred for applications demanding rigidity and dimensional integrity.

Table of Comparison

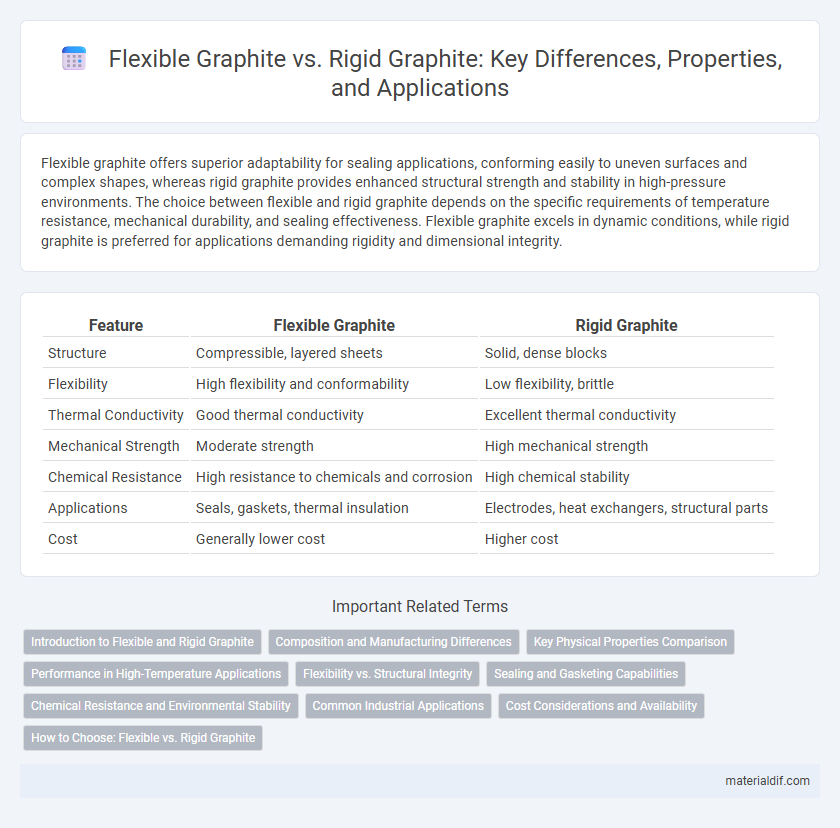

| Feature | Flexible Graphite | Rigid Graphite |

|---|---|---|

| Structure | Compressible, layered sheets | Solid, dense blocks |

| Flexibility | High flexibility and conformability | Low flexibility, brittle |

| Thermal Conductivity | Good thermal conductivity | Excellent thermal conductivity |

| Mechanical Strength | Moderate strength | High mechanical strength |

| Chemical Resistance | High resistance to chemicals and corrosion | High chemical stability |

| Applications | Seals, gaskets, thermal insulation | Electrodes, heat exchangers, structural parts |

| Cost | Generally lower cost | Higher cost |

Introduction to Flexible and Rigid Graphite

Flexible graphite consists of expanded natural graphite flakes bonded together into sheets that can bend and conform to surfaces, making it ideal for sealing and thermal management applications. Rigid graphite, on the other hand, is characterized by a denser, more compact structure that offers high strength, stability, and excellent electrical conductivity, commonly used in electrodes and industrial components. Understanding the differences in structure and mechanical properties between flexible and rigid graphite is crucial for selecting the right material in energy storage, metallurgy, and aerospace industries.

Composition and Manufacturing Differences

Flexible graphite consists of expanded natural graphite flakes bound by a resin or binder, allowing it to be compressed into thin, pliable sheets using a calendaring or pressing process. Rigid graphite, or isostatic graphite, is formed by mixing fine graphite powder with a pitch binder, then compacted under high pressure and baked at elevated temperatures to create a dense, hard material. The key manufacturing difference lies in flexible graphite's laminar structure enabling flexibility, while rigid graphite's isotropic microstructure provides high mechanical strength and thermal conductivity.

Key Physical Properties Comparison

Flexible graphite exhibits high compressibility and excellent thermal conductivity, making it ideal for sealing applications requiring adaptability and heat resistance. Rigid graphite offers superior mechanical strength and structural stability, with higher density and lower porosity, suitable for high-load, wear-resistant components. Key physical properties contrast includes flexibility (high in flexible graphite), hardness (greater in rigid graphite), and thermal expansion rates, tailored to specific industrial uses.

Performance in High-Temperature Applications

Flexible graphite exhibits superior thermal stability and excellent compressibility, making it ideal for high-temperature applications requiring tight sealing and conformability. Rigid graphite offers enhanced mechanical strength and structural integrity, which is beneficial in environments where durability under thermal stress is crucial. Both materials perform reliably at elevated temperatures, but flexible graphite excels in dynamic sealing performance while rigid graphite is preferred for load-bearing components.

Flexibility vs. Structural Integrity

Flexible graphite exhibits superior flexibility due to its ability to compress and conform to irregular surfaces, making it ideal for gasketing and sealing applications where adaptability is crucial. Rigid graphite, in contrast, maintains higher structural integrity and mechanical strength, suitable for high-temperature environments requiring dimensional stability and resistance to deformation. The choice between flexible and rigid graphite depends on balancing flexibility needs against the necessity for consistent structural support in specific industrial uses.

Sealing and Gasketing Capabilities

Flexible graphite exhibits superior sealing and gasketing capabilities due to its ability to conform to irregular surfaces and withstand significant thermal expansion without cracking. Rigid graphite, while offering excellent chemical resistance and high-temperature stability, often lacks the necessary flexibility to maintain an effective seal under dynamic pressure or vibration. For applications requiring reliable sealing performance in fluctuating conditions, flexible graphite is the preferred material choice.

Chemical Resistance and Environmental Stability

Flexible graphite exhibits superior chemical resistance due to its layered structure, enabling it to withstand exposure to strong acids, alkalis, and solvents without degradation. Its environmental stability allows it to maintain integrity under extreme temperatures and corrosive atmospheres, making it ideal for sealing and gasketing applications. Rigid graphite, while chemically resistant, tends to be more brittle and less adaptable to thermal cycling, which can limit its durability in dynamic or harsh environmental conditions.

Common Industrial Applications

Flexible graphite is widely used in sealing applications such as gaskets and packing materials in chemical processing, petrochemical, and power generation industries due to its excellent compressibility and thermal stability. Rigid graphite finds common applications in electrodes for electric arc furnaces, battery anodes, and heat exchangers, leveraging its high mechanical strength and electrical conductivity. Both types are integral in industries requiring durable materials that withstand high temperatures and corrosive environments.

Cost Considerations and Availability

Flexible graphite offers cost advantages due to its lower production complexity and readily available raw materials, making it more economical for large-scale applications. Rigid graphite generally incurs higher costs because of its extensive processing requirements and specialized manufacturing techniques, limiting its widespread availability. Market demand and material sourcing also influence the price and accessibility of both flexible and rigid graphite, with flexible graphite typically more abundant and accessible globally.

How to Choose: Flexible vs. Rigid Graphite

Choosing between flexible and rigid graphite depends on the specific application requirements such as thermal conductivity, mechanical strength, and flexibility. Flexible graphite offers superior sealing capabilities and resilience in dynamic environments, making it ideal for gasketing and high-temperature sealing where compression recovery is crucial. Rigid graphite, with its higher stiffness and structural integrity, suits applications demanding dimensional stability and resistance to deformation under mechanical stress.

Flexible Graphite vs Rigid Graphite Infographic

materialdif.com

materialdif.com