Graphite block machining offers precise shaping and customization by removing material from solid graphite, ideal for complex, high-strength applications. Graphite sheet lamination involves layering thin graphite sheets bonded together, providing enhanced flexibility and improved thermal conductivity. Choosing between these methods depends on the specific mechanical and thermal requirements of the graphite component.

Table of Comparison

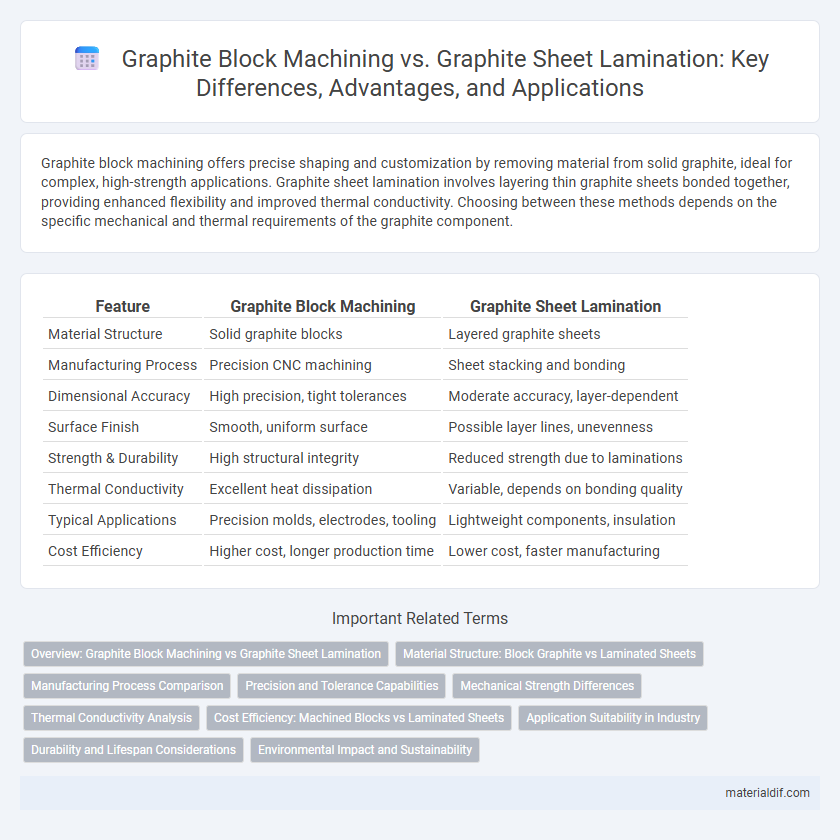

| Feature | Graphite Block Machining | Graphite Sheet Lamination |

|---|---|---|

| Material Structure | Solid graphite blocks | Layered graphite sheets |

| Manufacturing Process | Precision CNC machining | Sheet stacking and bonding |

| Dimensional Accuracy | High precision, tight tolerances | Moderate accuracy, layer-dependent |

| Surface Finish | Smooth, uniform surface | Possible layer lines, unevenness |

| Strength & Durability | High structural integrity | Reduced strength due to laminations |

| Thermal Conductivity | Excellent heat dissipation | Variable, depends on bonding quality |

| Typical Applications | Precision molds, electrodes, tooling | Lightweight components, insulation |

| Cost Efficiency | Higher cost, longer production time | Lower cost, faster manufacturing |

Overview: Graphite Block Machining vs Graphite Sheet Lamination

Graphite block machining involves shaping solid graphite blocks using precision cutting tools to create complex components with high thermal and electrical conductivity, essential in industries like aerospace and electronics. Graphite sheet lamination, on the other hand, produces layered graphite sheets bonded under heat and pressure, offering flexibility, uniform thickness, and excellent sealing properties for applications such as gaskets and thermal management. The choice between block machining and sheet lamination depends on the required mechanical strength, dimensional accuracy, and form factor for specific industrial uses.

Material Structure: Block Graphite vs Laminated Sheets

Graphite block machining involves shaping a solid, homogenous block of graphite with consistent density and uniform grain structure, resulting in high mechanical strength and thermal conductivity. In contrast, graphite sheet lamination consists of stacking multiple thin graphite sheets bonded together, which can introduce anisotropy and layer interfaces affecting thermal and electrical properties. The solid block structure provides better durability and precision for intricate parts, while laminated sheets offer flexibility in thickness but may compromise structural integrity due to the layered composition.

Manufacturing Process Comparison

Graphite block machining involves shaping solid graphite blocks through CNC milling or grinding, offering high precision and excellent surface finish for complex components. Graphite sheet lamination, on the other hand, fabricates parts by layering and bonding thin graphite sheets, enabling customization of thickness and improved material uniformity but with lower dimensional accuracy. The choice between these manufacturing processes depends on application requirements such as component complexity, tolerance levels, and production volume.

Precision and Tolerance Capabilities

Graphite block machining offers superior precision and tighter tolerance capabilities compared to graphite sheet lamination, enabling intricate and complex geometries with accuracy often within microns. The subtractive nature of block machining allows for consistent dimensional control and fine surface finishes essential in high-performance applications. In contrast, graphite sheet lamination typically exhibits larger tolerances and less dimensional stability due to layer stacking and adhesive variability.

Mechanical Strength Differences

Graphite block machining offers superior mechanical strength due to its dense and uniform microstructure, resulting in higher fracture toughness and resistance to mechanical stress. In contrast, graphite sheet lamination typically exhibits anisotropic mechanical properties, with reduced strength and durability along the lamination interfaces. The inherent bonding weaknesses in laminated graphite sheets make them less suitable for high-load applications compared to solid graphite blocks.

Thermal Conductivity Analysis

Graphite block machining typically yields higher thermal conductivity due to its dense, isotropic structure, enabling more efficient heat transfer compared to graphite sheet lamination, which often contains interlayer interfaces that impede thermal flow. The laminated sheets exhibit anisotropic thermal properties, with reduced conductivity across layers caused by imperfect bonding and potential voids. Consequently, applications demanding superior thermal management commonly prefer machined graphite blocks for optimized heat dissipation performance.

Cost Efficiency: Machined Blocks vs Laminated Sheets

Machined graphite blocks offer high precision and durability but come with higher upfront costs due to complex cutting processes and material waste. Graphite sheet lamination typically reduces material costs by using thinner, layered sheets that are easier and faster to produce, resulting in lower overall expenses. Cost efficiency depends on project scale and application requirements, with lamination favored for large-volume, less intricate parts and machining preferred for detailed, high-performance components.

Application Suitability in Industry

Graphite block machining is ideal for industries requiring high precision components such as aerospace and electronics, where complex shapes and tight tolerances are critical. Graphite sheet lamination excels in applications demanding flexibility and thermal management, commonly used in battery technology and thermal insulation. Selecting between these methods depends on the specific industrial needs for mechanical strength, thermal conductivity, and manufacturing scalability.

Durability and Lifespan Considerations

Graphite block machining offers superior durability due to its solid, dense structure, which withstands high temperatures and mechanical stress better than laminated graphite sheets. Graphite sheet lamination, while lighter and more flexible, typically exhibits a shorter lifespan as layers are prone to delamination and wear under continuous thermal cycling. Choosing between these methods depends on the application's required durability and expected service life, with block machining favored for long-term, high-stress environments.

Environmental Impact and Sustainability

Graphite block machining generates significant industrial waste and consumes high energy due to the material removal process, impacting environmental sustainability negatively. In contrast, graphite sheet lamination offers a more sustainable alternative by minimizing waste through additive layering techniques and reducing energy consumption. The laminated approach further enables recycling of off-cuts, enhancing resource efficiency and lowering carbon footprint in graphite manufacturing.

Graphite Block Machining vs Graphite Sheet Lamination Infographic

materialdif.com

materialdif.com