Graphite pet quality is determined primarily by its purity level, with higher purity indicating fewer impurities such as ash, sulfur, and moisture that can compromise performance. Impurity content directly affects the thermal conductivity, lubricity, and electrical properties of graphite, making low-impurity graphite essential for demanding industrial applications. Ensuring minimal contamination levels enhances the efficiency and lifespan of graphite pet products in various technological uses.

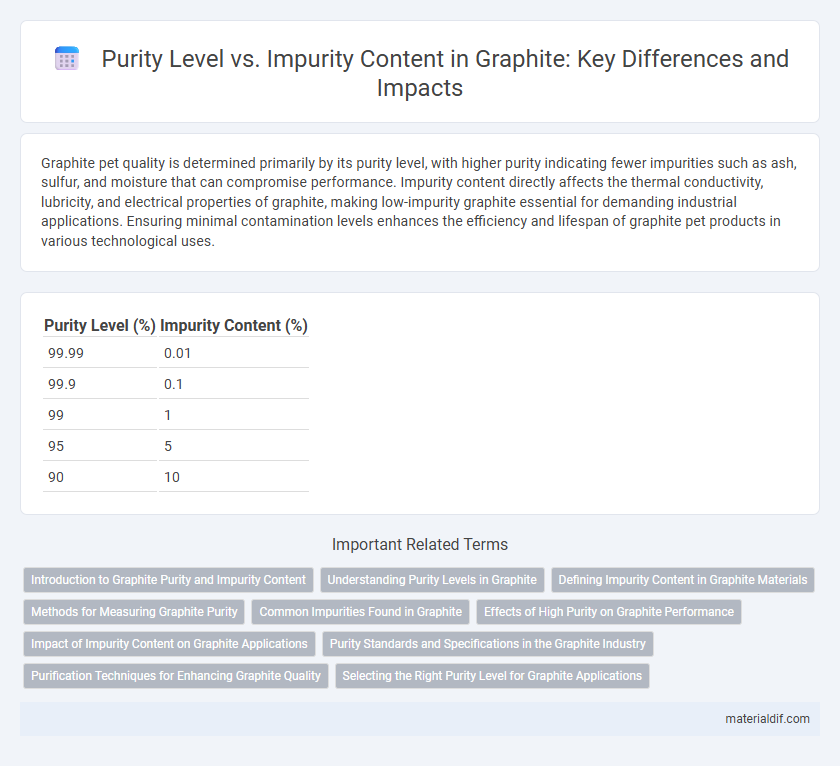

Table of Comparison

| Purity Level (%) | Impurity Content (%) |

|---|---|

| 99.99 | 0.01 |

| 99.9 | 0.1 |

| 99 | 1 |

| 95 | 5 |

| 90 | 10 |

Introduction to Graphite Purity and Impurity Content

Graphite purity levels directly influence its electrical conductivity, thermal stability, and mechanical strength, with high-purity graphite typically containing less than 0.1% impurity content. Impurities such as sulfur, iron, and silica disrupt the graphite lattice structure, reducing performance in applications like lithium-ion batteries and nuclear reactors. Controlling impurity content through advanced purification methods ensures optimized graphite quality for industrial and technological uses.

Understanding Purity Levels in Graphite

Purity levels in graphite are typically measured by the percentage of carbon content, with high-purity graphite exceeding 99.9% carbon. Impurity content, including elements like sulfur, iron, and silicon, directly affects the electrical conductivity, thermal stability, and overall performance of graphite products. Controlling impurity levels is crucial for applications in batteries, refractories, and electronics where material consistency and performance are critical.

Defining Impurity Content in Graphite Materials

Impurity content in graphite materials refers to the presence and concentration of foreign elements such as silicon, iron, and aluminum within the graphite matrix, which directly affects the purity level. High purity graphite typically contains impurity levels below 100 ppm, essential for applications requiring excellent electrical conductivity and thermal stability. Accurate quantification of impurities using techniques like ICP-MS or XRF ensures optimal performance in industries such as electronics, energy storage, and nuclear reactors.

Methods for Measuring Graphite Purity

Graphite purity is primarily determined by measuring impurity content using techniques such as X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP-MS), and combustion analysis. These methods provide precise quantification of metallic and non-metallic impurities, crucial for applications requiring ultra-high purity graphite. Accurate impurity content assessment ensures performance consistency in batteries, refractories, and electronic materials.

Common Impurities Found in Graphite

Graphite purity level is critically influenced by the presence of common impurities such as silica (SiO2), sulfur (S), iron (Fe), and other trace metals, which can significantly affect its electrical and thermal conductivity. High-purity graphite typically contains over 99% carbon with minimal impurity content, often less than 1%, ensuring optimal performance in industrial applications like battery anodes and refractories. Impurities like ash and moisture are carefully controlled through refining processes to enhance the structural integrity and chemical stability of graphite materials.

Effects of High Purity on Graphite Performance

High purity graphite, typically containing less than 50 ppm impurities, exhibits superior electrical conductivity and thermal stability compared to lower purity grades. Reduced impurity content minimizes defects and structural inconsistencies, enhancing the material's mechanical strength and corrosion resistance. These performance improvements are critical in advanced applications such as lithium-ion battery anodes and high-temperature industrial processes.

Impact of Impurity Content on Graphite Applications

High impurity content in graphite significantly reduces its electrical conductivity and thermal stability, limiting its effectiveness in high-performance applications such as batteries and aerospace components. Purity levels above 99.9% enhance graphite's chemical inertness and mechanical strength, making it suitable for semiconductor manufacturing and nuclear reactors. Therefore, controlling impurity content is critical to optimizing graphite's functional properties across diverse industrial uses.

Purity Standards and Specifications in the Graphite Industry

Graphite purity levels are crucial for meeting industry specifications, with high-purity graphite typically exceeding 99.9% carbon content and impurity elements such as sulfur, ash, and phosphorus strictly limited to trace amounts below 0.1%. Purity standards in the graphite industry vary by application, with battery-grade and semiconductor-grade graphite demanding the highest specifications to ensure optimal electrical conductivity and chemical stability. Impurity content directly impacts performance characteristics, making rigorous quality control and advanced purification processes essential in producing graphite that complies with international standards like ASTM C560 and ISO 9001.

Purification Techniques for Enhancing Graphite Quality

Purification techniques for enhancing graphite quality focus on reducing impurity content to achieve higher purity levels critical for advanced applications. Methods such as chemical leaching, thermal treatment, and flotation effectively remove metallic and non-metallic impurities, improving electrical conductivity and structural integrity. High-purity graphite with impurity levels below 100 ppm is essential for industries like lithium-ion batteries and electronic components.

Selecting the Right Purity Level for Graphite Applications

Selecting the appropriate purity level for graphite applications depends on the specific performance requirements and industry standards, with high-purity graphite (above 99.9%) essential for electronic and battery technologies due to minimal impurity content. Lower purity graphites, containing impurities such as ash, sulfur, and metals, are suitable for refractory and lubricating applications where minor contaminations have less impact. Understanding the balance between purity level and impurity types ensures optimal functionality, cost efficiency, and material longevity across diverse graphite uses.

Purity Level vs Impurity Content Infographic

materialdif.com

materialdif.com