Electrochemical etching offers precise control and minimal mechanical stress when shaping graphite, resulting in smoother surfaces and intricate patterns ideal for high-performance applications. Mechanical machining, while traditionally used, can introduce micro-cracks and surface defects due to physical forces, potentially compromising the structural integrity of graphite components. Choosing electrochemical etching enhances dimensional accuracy and surface quality, making it a preferred method for advanced graphite pet shaping processes.

Table of Comparison

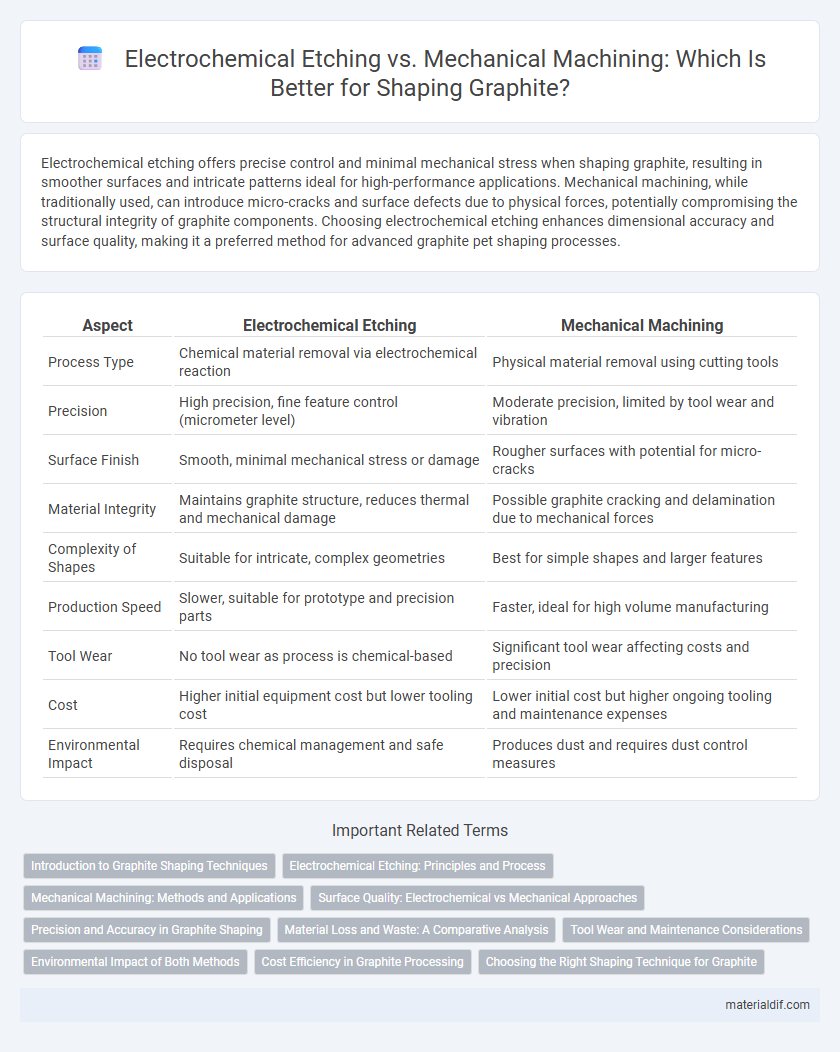

| Aspect | Electrochemical Etching | Mechanical Machining |

|---|---|---|

| Process Type | Chemical material removal via electrochemical reaction | Physical material removal using cutting tools |

| Precision | High precision, fine feature control (micrometer level) | Moderate precision, limited by tool wear and vibration |

| Surface Finish | Smooth, minimal mechanical stress or damage | Rougher surfaces with potential for micro-cracks |

| Material Integrity | Maintains graphite structure, reduces thermal and mechanical damage | Possible graphite cracking and delamination due to mechanical forces |

| Complexity of Shapes | Suitable for intricate, complex geometries | Best for simple shapes and larger features |

| Production Speed | Slower, suitable for prototype and precision parts | Faster, ideal for high volume manufacturing |

| Tool Wear | No tool wear as process is chemical-based | Significant tool wear affecting costs and precision |

| Cost | Higher initial equipment cost but lower tooling cost | Lower initial cost but higher ongoing tooling and maintenance expenses |

| Environmental Impact | Requires chemical management and safe disposal | Produces dust and requires dust control measures |

Introduction to Graphite Shaping Techniques

Electrochemical etching offers precise control and minimal mechanical stress when shaping graphite, enabling intricate patterns with clean edges. Mechanical machining, such as milling or turning, provides faster material removal but risks surface damage and microcracks due to mechanical forces. Selecting the appropriate technique depends on the desired accuracy, surface finish, and production volume for graphite components.

Electrochemical Etching: Principles and Process

Electrochemical etching of graphite involves using an electrolyte solution and controlled electrical current to selectively remove material through anodic dissolution, enabling precise and clean feature formation without inducing mechanical stress or fractures. The process parameters such as current density, electrolyte composition, and voltage are optimized to achieve high-resolution patterns and smooth surface finishes, which are critical for advanced applications in electronics and sensor technologies. This technique offers superior dimensional accuracy and minimal tool wear compared to mechanical machining, making it ideal for intricate graphite components.

Mechanical Machining: Methods and Applications

Mechanical machining of graphite involves precision processes such as milling, turning, grinding, and drilling, enabling the fabrication of complex shapes with tight tolerances. These methods leverage graphite's brittle yet machinable nature to produce components used in electrodes, heat exchangers, and molds for metal casting. Applications benefit from the high thermal conductivity and wear resistance of machined graphite parts, making mechanical machining essential in industries like aerospace, electronics, and metallurgy.

Surface Quality: Electrochemical vs Mechanical Approaches

Electrochemical etching produces superior surface quality on graphite by minimizing mechanical stresses and surface defects, resulting in smoother and more precise contours. Mechanical machining often causes micro-cracks and surface roughness due to tool wear and abrasive forces, compromising the integrity and performance of the graphite components. The electrochemical process ensures enhanced dimensional accuracy and reduced post-processing requirements compared to conventional mechanical methods.

Precision and Accuracy in Graphite Shaping

Electrochemical etching offers superior precision in graphite shaping due to its ability to remove material at the micro-level without mechanical stress, achieving accuracy within micrometer tolerances. Mechanical machining, while effective for bulk material removal, often introduces micro-cracks and surface irregularities that reduce dimensional accuracy and compromise the structural integrity of graphite components. Advanced electrochemical processes enable complex geometries with higher repeatability and minimal tool wear compared to conventional mechanical techniques.

Material Loss and Waste: A Comparative Analysis

Electrochemical etching of graphite minimizes material loss by precisely removing layers with controlled electrochemical reactions, resulting in less waste compared to mechanical machining, which often causes excessive graphite chipping and dust generation. The selective nature of electrochemical etching enhances material utilization efficiency, preserving graphite integrity and reducing scrap rates. Mechanical machining, despite being widely used, frequently leads to higher material waste due to its abrasive cutting processes and the brittleness of graphite.

Tool Wear and Maintenance Considerations

Electrochemical etching offers minimal tool wear compared to mechanical machining, as it relies on controlled chemical reactions rather than physical abrasion to shape graphite. Mechanical machining subjects cutting tools to high friction and heat, resulting in frequent tool replacements and increased maintenance costs. The reduced tool degradation in electrochemical etching significantly lowers downtime and extends the lifespan of shaping equipment in graphite fabrication.

Environmental Impact of Both Methods

Electrochemical etching of graphite generates fewer airborne particulates and reduces dust emissions compared to mechanical machining, resulting in lower occupational health risks. The process also minimizes abrasive tool wear and waste generation, reducing environmental pollutant discharge. Mechanical machining produces significant graphite dust and noise pollution, leading to increased environmental and safety concerns.

Cost Efficiency in Graphite Processing

Electrochemical etching offers superior cost efficiency in graphite processing by minimizing material waste and reducing tool wear compared to mechanical machining. Mechanical machining often involves higher labor costs and frequent tool replacements due to the abrasive nature of graphite. The precision of electrochemical etching reduces post-processing requirements, resulting in overall lower production expenses.

Choosing the Right Shaping Technique for Graphite

Electrochemical etching offers precise, residue-free shaping of graphite with minimal mechanical stress, making it ideal for complex or delicate designs. Mechanical machining provides faster material removal and is cost-effective for simpler shapes but can introduce surface defects and microcracks. The choice depends on the graphite grade, desired tolerance, and application requirements, balancing precision with production efficiency.

Electrochemical Etching vs Mechanical Machining (for shaping graphite) Infographic

materialdif.com

materialdif.com