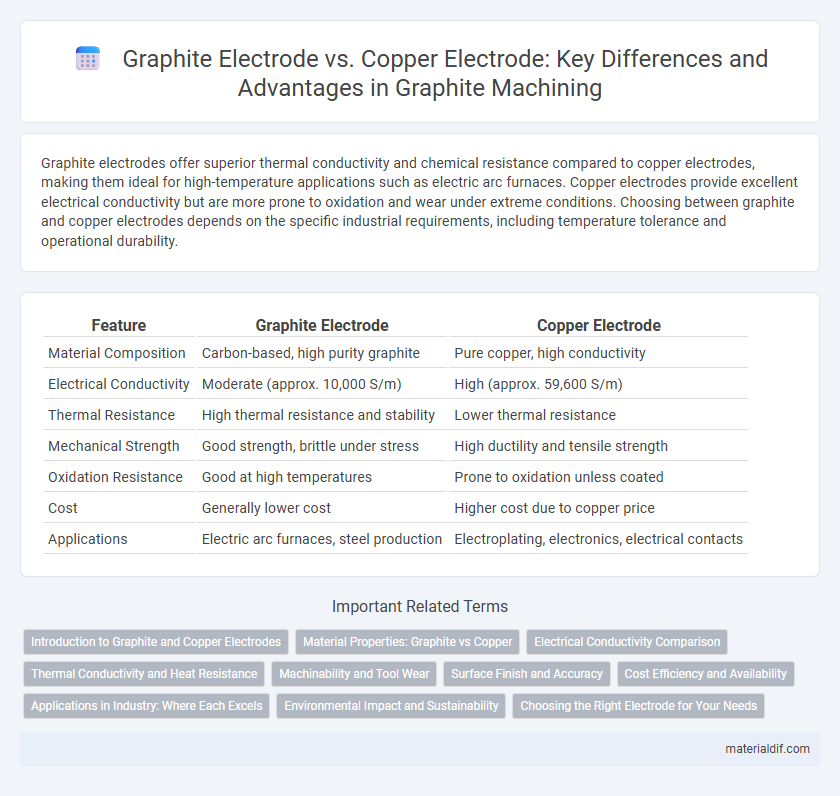

Graphite electrodes offer superior thermal conductivity and chemical resistance compared to copper electrodes, making them ideal for high-temperature applications such as electric arc furnaces. Copper electrodes provide excellent electrical conductivity but are more prone to oxidation and wear under extreme conditions. Choosing between graphite and copper electrodes depends on the specific industrial requirements, including temperature tolerance and operational durability.

Table of Comparison

| Feature | Graphite Electrode | Copper Electrode |

|---|---|---|

| Material Composition | Carbon-based, high purity graphite | Pure copper, high conductivity |

| Electrical Conductivity | Moderate (approx. 10,000 S/m) | High (approx. 59,600 S/m) |

| Thermal Resistance | High thermal resistance and stability | Lower thermal resistance |

| Mechanical Strength | Good strength, brittle under stress | High ductility and tensile strength |

| Oxidation Resistance | Good at high temperatures | Prone to oxidation unless coated |

| Cost | Generally lower cost | Higher cost due to copper price |

| Applications | Electric arc furnaces, steel production | Electroplating, electronics, electrical contacts |

Introduction to Graphite and Copper Electrodes

Graphite electrodes are composed primarily of carbon and are widely used in electric arc furnaces due to their high thermal conductivity, electrical conductivity, and resistance to thermal shock. Copper electrodes, made of highly conductive copper, excel in applications requiring superior electrical conductivity and enhanced corrosion resistance but are less tolerant to high temperatures compared to graphite. Understanding these fundamental material properties is crucial for selecting the appropriate electrode in industrial processes involving electrical discharge machining or arc melting.

Material Properties: Graphite vs Copper

Graphite electrodes exhibit high thermal conductivity, excellent electrical conductivity, and superior resistance to thermal shock, making them ideal for electric arc furnaces. Copper electrodes possess higher electrical conductivity and better ductility but suffer from lower thermal resistance and are prone to oxidation under high-temperature conditions. The choice between graphite and copper electrodes depends on the application's thermal stability requirements and electrical performance needs.

Electrical Conductivity Comparison

Graphite electrodes exhibit lower electrical conductivity compared to copper electrodes, typically ranging from 10 to 50 S/cm, whereas copper's conductivity is approximately 5.96 x 10^5 S/cm, making copper significantly more efficient for electrical current conduction. The resistivity of graphite, around 3 x 10^-5 O*m, is much higher than copper's resistivity of 1.68 x 10^-8 O*m, affecting energy efficiency in applications demanding minimal power loss. Copper electrodes are preferred in high-conductivity scenarios, while graphite is favored for its thermal stability and chemical resistance despite lower conductivity.

Thermal Conductivity and Heat Resistance

Graphite electrodes exhibit lower thermal conductivity than copper electrodes, with values around 120 W/m*K compared to copper's 400 W/m*K, making graphite less efficient at heat transfer. However, graphite electrodes demonstrate superior heat resistance, tolerating temperatures up to 3000degC without significant degradation, whereas copper electrodes melt at 1085degC. These properties make graphite electrodes ideal for high-temperature applications such as electric arc furnaces, where thermal stability outweighs thermal conductivity.

Machinability and Tool Wear

Graphite electrodes exhibit superior machinability compared to copper electrodes due to their lower hardness and excellent thermal conductivity, which allows for easier cutting and shaping. Tool wear is significantly reduced when machining graphite because its softer, abrasive nature generates less friction and heat during processing. In contrast, copper electrodes require more durable tooling to withstand higher resistance and greater heat buildup, leading to increased tool wear and maintenance costs.

Surface Finish and Accuracy

Graphite electrodes offer a smoother surface finish due to their fine grain structure, reducing machining marks and improving electrical conductivity. Copper electrodes excel in accuracy because of their superior thermal conductivity and ability to maintain dimensional stability during the EDM process. While graphite provides cost-effective machining with moderate precision, copper electrodes deliver high precision and finer detail in electrode finishing.

Cost Efficiency and Availability

Graphite electrodes offer superior cost efficiency due to their lower production costs and longer lifespan compared to copper electrodes, which are more expensive and prone to quicker wear. The abundant availability of graphite as a raw material contributes to its affordability, while copper's limited supply and high market demand drive up prices. Industries prioritizing cost-effective and sustainable solutions frequently prefer graphite electrodes for applications like electric arc furnaces and steel manufacturing.

Applications in Industry: Where Each Excels

Graphite electrodes dominate in electric arc furnace steelmaking due to their high conductivity, thermal resistance, and durability under extreme temperatures, making them ideal for melting scrap steel. Copper electrodes excel in electrical discharge machining (EDM) and precision welding applications because of their superior electrical conductivity, excellent thermal conductivity, and resistance to wear during fine, controlled electrical discharges. Industries favor graphite for heavy-duty smelting and copper for precision tooling, reflecting their distinct performance advantages in heat management and electrical conduction.

Environmental Impact and Sustainability

Graphite electrodes exhibit a lower environmental impact compared to copper electrodes due to their higher recyclability and longer lifespan, reducing waste generation in industrial applications. The production of graphite electrodes consumes less energy and generates fewer greenhouse gas emissions than copper electrode manufacturing, contributing to overall sustainability goals. These factors position graphite electrodes as a more eco-friendly choice in sectors like steel manufacturing and electric arc furnaces.

Choosing the Right Electrode for Your Needs

Graphite electrodes offer high thermal conductivity and excellent resistance to thermal shock, making them ideal for electric arc furnace applications that require consistent performance under extreme heat. Copper electrodes provide superior electrical conductivity and durability in processes where precision and minimal resistance are critical, such as spot welding and electrical discharge machining. Selecting the right electrode depends on balancing factors like operating temperature, electrical conductivity needs, and the specific industrial application to ensure optimal efficiency and lifespan.

Graphite Electrode vs Copper Electrode Infographic

materialdif.com

materialdif.com