Graphite felt offers superior flexibility and higher thermal conductivity, making it ideal for applications requiring efficient heat dissipation and mechanical resilience. Graphite foam provides a lightweight structure with excellent compressive strength and porous properties suitable for energy storage and filtration uses. Choosing between graphite felt and graphite foam depends on the balance needed between thermal performance and structural support in specific industrial processes.

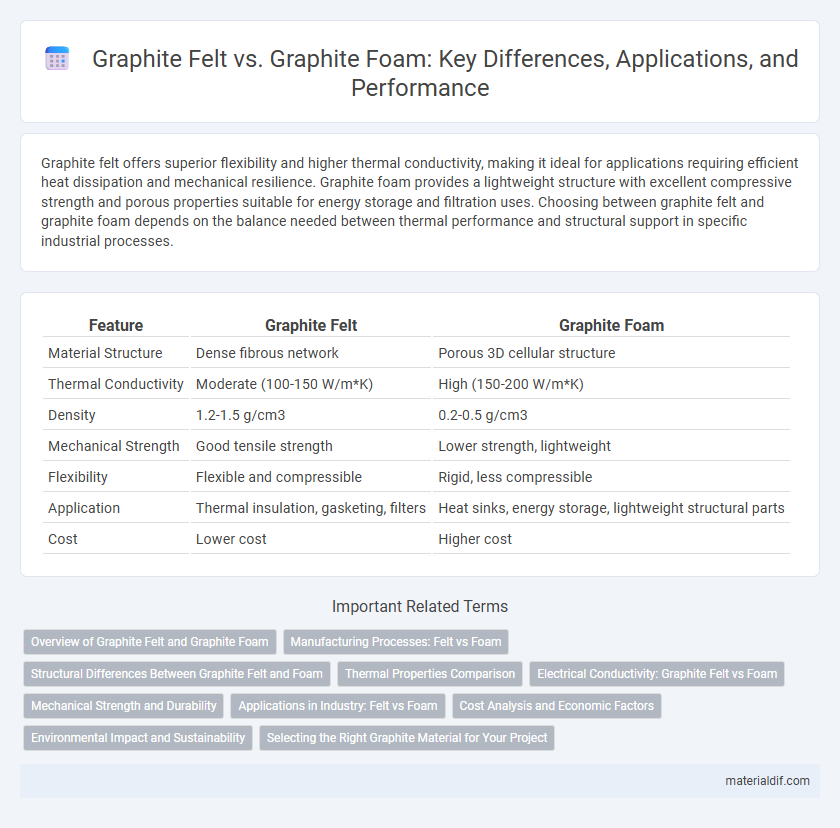

Table of Comparison

| Feature | Graphite Felt | Graphite Foam |

|---|---|---|

| Material Structure | Dense fibrous network | Porous 3D cellular structure |

| Thermal Conductivity | Moderate (100-150 W/m*K) | High (150-200 W/m*K) |

| Density | 1.2-1.5 g/cm3 | 0.2-0.5 g/cm3 |

| Mechanical Strength | Good tensile strength | Lower strength, lightweight |

| Flexibility | Flexible and compressible | Rigid, less compressible |

| Application | Thermal insulation, gasketing, filters | Heat sinks, energy storage, lightweight structural parts |

| Cost | Lower cost | Higher cost |

Overview of Graphite Felt and Graphite Foam

Graphite felt is a porous, flexible material composed of interconnected graphite fibers offering high thermal conductivity and excellent chemical stability, commonly used in high-temperature insulation and filtration. Graphite foam, characterized by its lightweight, solid yet porous structure, provides superior thermal management properties, making it ideal for applications requiring efficient heat dissipation. Both materials leverage graphite's unique properties but differ significantly in form and specific performance characteristics, with felt emphasizing flexibility and foam prioritizing rigidity and low density.

Manufacturing Processes: Felt vs Foam

Graphite felt is manufactured through the needling process, where fine graphite fibers are entangled to form a dense, porous mat with high mechanical strength and thermal conductivity. Graphite foam, on the other hand, is produced using a polymer foam impregnation method followed by high-temperature carbonization and graphitization, resulting in a lightweight structure with interconnected pores and lower density. The needling technique in felt emphasizes fiber orientation and compression, while foam production prioritizes pore size control and uniformity for thermal management applications.

Structural Differences Between Graphite Felt and Foam

Graphite felt consists of interwoven carbon fibers forming a dense, porous mat with high tensile strength, while graphite foam features a rigid, open-cell structure composed of interconnected graphite ligaments. The felt's fibrous microstructure offers superior flexibility and conformability, whereas the foam's macroporous network provides enhanced mechanical rigidity and low density. These structural distinctions influence their thermal conductivity, mechanical properties, and suitability for applications such as thermal management and structural reinforcement.

Thermal Properties Comparison

Graphite felt exhibits higher thermal conductivity along the fiber axis, making it ideal for applications requiring efficient heat transfer and uniform temperature distribution. Graphite foam typically offers lower density and isotropic thermal conductivity, which supports enhanced thermal insulation with moderate heat dissipation capabilities. The choice between graphite felt and graphite foam depends on specific thermal management requirements such as directional heat flow versus insulation.

Electrical Conductivity: Graphite Felt vs Foam

Graphite felt exhibits higher electrical conductivity compared to graphite foam due to its dense fibrous structure, allowing more efficient electron transport paths. The interconnected carbon fibers in graphite felt create continuous conductive networks, while graphite foam's porous matrix leads to reduced electrical pathway continuity. Electrical conductivity values for graphite felt can reach up to 10^4 S/m, whereas graphite foam typically ranges lower, around 10^2 to 10^3 S/m, impacting their suitability for different electrical applications.

Mechanical Strength and Durability

Graphite felt exhibits superior mechanical strength and durability compared to graphite foam due to its dense fiber network, which provides excellent resistance to compression and wear. Graphite foam, while lightweight and possessing high thermal conductivity, typically has lower mechanical strength and is more susceptible to damage under mechanical stress. In industrial applications requiring long-term structural integrity and toughness, graphite felt is often the preferred material.

Applications in Industry: Felt vs Foam

Graphite felt offers superior thermal insulation and chemical resistance, making it ideal for high-temperature industrial applications such as furnace linings and thermal barriers. Graphite foam provides high thermal conductivity and lightweight structural support, commonly used in heat exchangers and electronic cooling systems. The choice between felt and foam depends on specific requirements for insulation versus heat dissipation in industrial environments.

Cost Analysis and Economic Factors

Graphite felt generally offers lower initial costs compared to graphite foam due to simpler manufacturing processes and widespread availability, making it more cost-effective for large-scale industrial applications. Graphite foam, however, provides superior thermal conductivity and structural properties, which can lead to long-term economic benefits through improved energy efficiency and reduced maintenance expenses. The choice between graphite felt and graphite foam should consider both upfront investment and lifecycle cost implications based on specific operational requirements.

Environmental Impact and Sustainability

Graphite felt exhibits lower environmental impact due to its recyclability and durability, reducing waste generation in industrial applications compared to graphite foam. Graphite foam, while offering superior thermal insulation properties, is typically more energy-intensive to produce and less commonly recycled, leading to a larger carbon footprint. Sustainable use of graphite materials favors graphite felt for its extended lifespan and reduced resource consumption during manufacturing.

Selecting the Right Graphite Material for Your Project

Graphite felt offers superior thermal insulation and flexibility, making it ideal for sealing and gasketing applications where high heat resistance and compressibility are essential. Graphite foam provides exceptional lightweight structure and thermal conductivity, suitable for heat exchangers and lightweight thermal management solutions. Selecting the right graphite material depends on whether the priority is thermal insulation and durability (graphite felt) or enhanced heat transfer combined with minimal weight (graphite foam).

Graphite Felt vs Graphite Foam Infographic

materialdif.com

materialdif.com