Machining graphite involves precisely cutting and shaping high-density graphite blocks to create components with tight tolerances and smooth finishes, ideal for custom or intricate parts. Extruding graphite, on the other hand, forces graphite material through a die to produce long lengths or shapes with consistent cross-sections, often used for large-scale or standard profiles. Both processes influence the material's microstructure and mechanical properties, impacting its suitability for specific applications such as electrodes or molds.

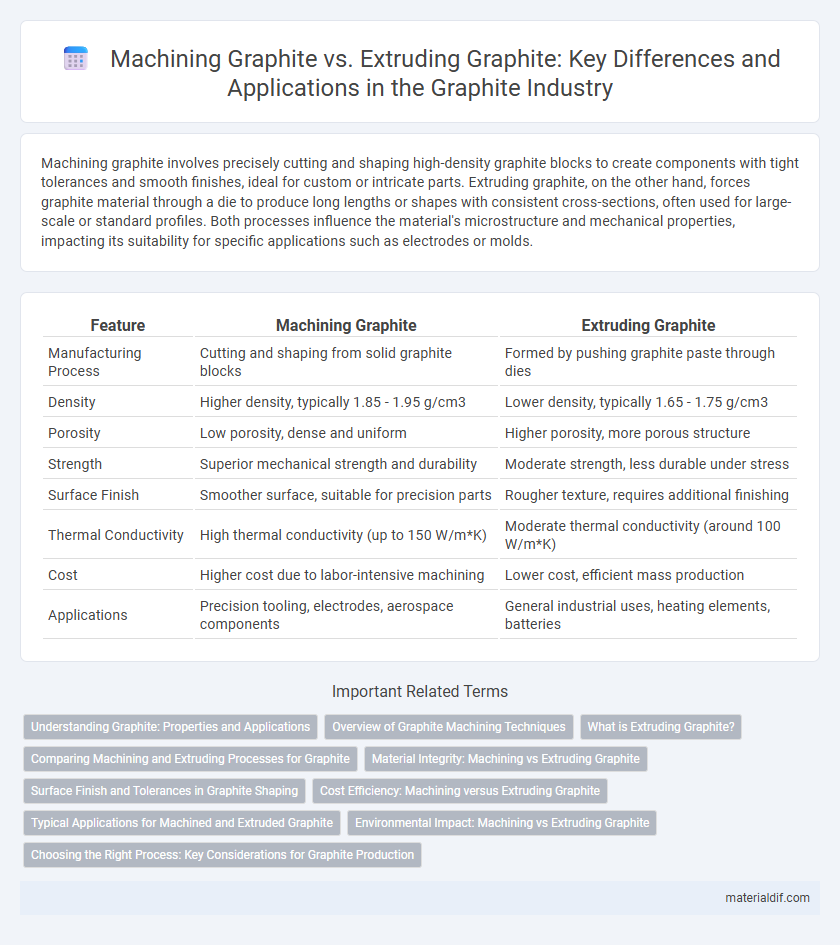

Table of Comparison

| Feature | Machining Graphite | Extruding Graphite |

|---|---|---|

| Manufacturing Process | Cutting and shaping from solid graphite blocks | Formed by pushing graphite paste through dies |

| Density | Higher density, typically 1.85 - 1.95 g/cm3 | Lower density, typically 1.65 - 1.75 g/cm3 |

| Porosity | Low porosity, dense and uniform | Higher porosity, more porous structure |

| Strength | Superior mechanical strength and durability | Moderate strength, less durable under stress |

| Surface Finish | Smoother surface, suitable for precision parts | Rougher texture, requires additional finishing |

| Thermal Conductivity | High thermal conductivity (up to 150 W/m*K) | Moderate thermal conductivity (around 100 W/m*K) |

| Cost | Higher cost due to labor-intensive machining | Lower cost, efficient mass production |

| Applications | Precision tooling, electrodes, aerospace components | General industrial uses, heating elements, batteries |

Understanding Graphite: Properties and Applications

Graphite's unique properties such as high thermal conductivity, excellent lubricity, and chemical inertness make it ideal for both machining and extruding processes. Machining graphite allows precise shaping for applications like electrodes, molds, and seals, leveraging its hardness and brittleness to achieve fine details. Extruding graphite, on the other hand, produces uniform profiles used in batteries, brushes, and heat exchangers, optimizing density and strength through controlled material flow.

Overview of Graphite Machining Techniques

Graphite machining techniques primarily include traditional machining methods such as milling, turning, and grinding, which offer high precision and surface finish for complex shapes. Extruding graphite, on the other hand, involves forcing softened graphite material through a die to create uniform cross-sectional profiles, ideal for producing rods and tubes at scale. Machining graphite provides greater flexibility for custom, intricate designs, while extrusion is cost-effective for high-volume production of standardized components.

What is Extruding Graphite?

Extruding graphite involves forcing graphite material through a shaped die to create uniform, continuous profiles with precise dimensions, ideal for complex geometries and high-strength applications. This process enhances material density and structural integrity compared to natural graphite, making it suitable for components requiring consistent mechanical properties. Machining graphite, conversely, entails cutting or shaping pre-formed graphite blocks, often used for custom or intricate pieces where extrusion is not feasible.

Comparing Machining and Extruding Processes for Graphite

Machining graphite involves precisely cutting and shaping high-density, isotropic graphite blocks using CNC tools, resulting in superior dimensional accuracy and smoother surface finishes ideal for applications requiring tight tolerances. Extruding graphite, on the other hand, presses graphite powder mixed with binders through a die to form consistent, continuous profiles with easier production scalability but lower mechanical strength and surface quality compared to machined graphite. Choosing between machining and extruding depends on the required part complexity, performance specifications, and production volume, with machining favored for precision components and extruding suited for simpler, larger-scale shapes.

Material Integrity: Machining vs Extruding Graphite

Machining graphite preserves material integrity by shaping high-density, isotropic blocks with minimal internal stress, resulting in superior strength and thermal stability. In contrast, extruding graphite involves forcing powdered graphite through a die, which can introduce porosity and anisotropy that compromise mechanical properties. Therefore, machined graphite components often exhibit enhanced durability and consistent performance compared to extruded counterparts.

Surface Finish and Tolerances in Graphite Shaping

Machining graphite offers superior surface finish and tighter tolerances compared to extruding graphite, enabling precision components with smoother finishes critical for high-performance applications. Extruding graphite typically results in rougher surfaces and wider dimensional variations due to the nature of the extrusion process. Machined graphite parts achieve tolerances as fine as +-0.005 mm, while extruded parts generally maintain tolerances around +-0.05 mm, influencing the choice based on application requirements.

Cost Efficiency: Machining versus Extruding Graphite

Machining graphite involves higher labor and tooling costs due to precision cutting and shaping processes, making it less cost-efficient for large-scale production. Extruding graphite offers lower production costs by enabling continuous shaping with minimal waste, ideal for mass manufacturing. Overall, extruding graphite provides better cost efficiency compared to machining, especially for high-volume applications.

Typical Applications for Machined and Extruded Graphite

Machined graphite is commonly used in precision applications such as seals, vacuum furnace components, and electrodes for electric discharge machining due to its high dimensional accuracy and fine surface finish. Extruded graphite is typically employed in applications requiring larger shapes and lower cost, such as battery plates, heat exchangers, and brake linings, offering good mechanical strength and thermal conductivity. The choice between machined and extruded graphite depends on the specific performance requirements and complexity of the graphite component.

Environmental Impact: Machining vs Extruding Graphite

Machining graphite generates less waste material compared to extruding graphite, reducing environmental pollution from scrap disposal. Extruding graphite involves higher energy consumption due to the thermal processes required, increasing its carbon footprint. The choice between machining and extruding significantly affects resource efficiency and emissions in graphite manufacturing.

Choosing the Right Process: Key Considerations for Graphite Production

Machining graphite offers precision and fine detail, making it ideal for complex shapes and high-tolerance applications, while extruding graphite provides cost-effective mass production with consistent density and strength. Key considerations include the desired dimensional accuracy, production volume, and thermal conductivity requirements, as machining excels in customization whereas extrusion suits large-scale uniform parts. Material properties such as grain size and binder content also influence the choice, impacting machinability and structural integrity in end-use environments.

Machining Graphite vs Extruding Graphite Infographic

materialdif.com

materialdif.com