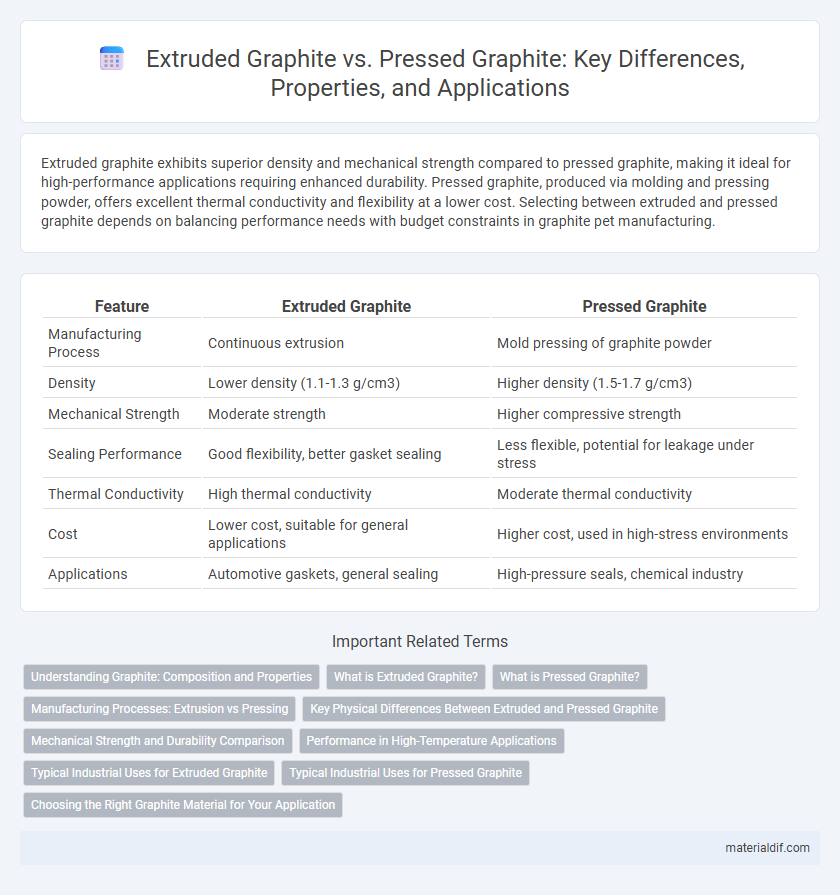

Extruded graphite exhibits superior density and mechanical strength compared to pressed graphite, making it ideal for high-performance applications requiring enhanced durability. Pressed graphite, produced via molding and pressing powder, offers excellent thermal conductivity and flexibility at a lower cost. Selecting between extruded and pressed graphite depends on balancing performance needs with budget constraints in graphite pet manufacturing.

Table of Comparison

| Feature | Extruded Graphite | Pressed Graphite |

|---|---|---|

| Manufacturing Process | Continuous extrusion | Mold pressing of graphite powder |

| Density | Lower density (1.1-1.3 g/cm3) | Higher density (1.5-1.7 g/cm3) |

| Mechanical Strength | Moderate strength | Higher compressive strength |

| Sealing Performance | Good flexibility, better gasket sealing | Less flexible, potential for leakage under stress |

| Thermal Conductivity | High thermal conductivity | Moderate thermal conductivity |

| Cost | Lower cost, suitable for general applications | Higher cost, used in high-stress environments |

| Applications | Automotive gaskets, general sealing | High-pressure seals, chemical industry |

Understanding Graphite: Composition and Properties

Extruded graphite is produced by mixing natural graphite flakes with a binder and forcing the mixture through a die, resulting in a highly anisotropic structure with superior mechanical strength and thermal conductivity along the extrusion direction. Pressed graphite, formed by compressing graphite powder and binder in a mold, exhibits more isotropic properties but generally lower density and mechanical strength compared to extruded graphite. The differences in microstructure and manufacturing processes directly influence their thermal stability, electrical conductivity, and suitability for high-temperature applications.

What is Extruded Graphite?

Extruded graphite is a form of synthetic graphite produced by compressing graphite particles with a binder and then forcing the mixture through a die to create uniform shapes, such as rods or sheets. This manufacturing process results in a material with high purity, excellent mechanical strength, and enhanced thermal conductivity compared to pressed graphite. Key applications of extruded graphite include high-temperature seals, heat exchangers, and electrical insulation components, where durability and precise dimensional properties are critical.

What is Pressed Graphite?

Pressed graphite, also known as molded graphite, is created by compressing natural or synthetic graphite powders under high pressure without extrusion, resulting in a densified, solid material with excellent mechanical strength and thermal conductivity. It is commonly used in gasket manufacturing and heat exchangers due to its superior resistance to chemical corrosion and high temperatures. Compared to extruded graphite, pressed graphite offers better isotropic properties and dimensional stability, making it suitable for applications requiring precise shapes and durability.

Manufacturing Processes: Extrusion vs Pressing

Extruded graphite is produced by forcing natural or synthetic graphite particles through a die under high pressure, resulting in a highly uniform, dense material with excellent mechanical strength and thermal conductivity. Pressed graphite is manufactured by compressing graphite powder mixed with a binder at high pressure and temperature, allowing for customized shapes but often yielding a less dense and mechanically weaker product compared to extrusion. The extrusion process enhances grain alignment, improving anisotropic properties, whereas pressing allows for greater flexibility in product geometry and lower production costs.

Key Physical Differences Between Extruded and Pressed Graphite

Extruded graphite exhibits a highly oriented, fibrous structure that provides superior mechanical strength and flexibility compared to the isotropic, granular composition of pressed graphite. Due to its anisotropic nature, extruded graphite offers enhanced tensile strength and better resistance to thermal shock, while pressed graphite features higher density and improved sealing properties. Understanding these key physical differences is critical for selecting the appropriate graphite type in demanding industrial applications such as sealing, thermal management, and chemical resistance.

Mechanical Strength and Durability Comparison

Extruded graphite exhibits superior mechanical strength due to its continuous grain structure, making it more resistant to stress and deformation compared to pressed graphite, which has a granular, sintered composition that results in lower tensile strength. The durability of extruded graphite is enhanced by its uniform density, providing better resistance to thermal shock and mechanical wear, whereas pressed graphite's porosity and bonded particles can lead to quicker degradation under harsh conditions. For applications requiring high mechanical integrity and prolonged service life, extruded graphite generally offers more reliable performance than pressed graphite.

Performance in High-Temperature Applications

Extruded graphite offers superior mechanical strength and thermal conductivity compared to pressed graphite, making it ideal for high-temperature applications requiring durability and efficient heat transfer. Its anisotropic structure enhances resistance to thermal shock and oxidation, which is crucial in environments exceeding 600degC. Pressed graphite, while more cost-effective, generally exhibits lower density and weaker mechanical properties, limiting its performance under extreme thermal stress.

Typical Industrial Uses for Extruded Graphite

Extruded graphite is widely used in high-temperature industrial applications such as heat exchangers, seals, and gaskets due to its superior mechanical strength and flexibility. Its continuous grain structure allows for easy machining and excellent resistance to thermal shock, making it ideal for complex shapes and custom components. Industries like chemical processing, power generation, and automotive manufacturing rely heavily on extruded graphite for reliable performance under extreme conditions.

Typical Industrial Uses for Pressed Graphite

Pressed graphite is commonly used in industrial applications requiring moderate mechanical strength and excellent thermal conductivity, such as gaskets, seals, and packing materials in chemical processing plants. Its machinability and resistance to chemical corrosion make it ideal for heat exchangers, valves, and flanges exposed to aggressive environments. Pressed graphite also finds use in electrical applications like brushes and electrodes due to its electrical conductivity and structural integrity.

Choosing the Right Graphite Material for Your Application

Extruded graphite offers higher density and better mechanical strength, making it ideal for applications requiring enhanced durability and thermal conductivity. Pressed graphite provides improved flexibility and cost-effectiveness, suitable for low-pressure sealing and gasketing solutions. Selecting the appropriate graphite material depends on factors like operational temperature, pressure conditions, and specific performance requirements of your application.

Extruded Graphite vs Pressed Graphite Infographic

materialdif.com

materialdif.com