Compression molding offers efficient shaping of graphite pet components by applying pressure and heat within a mold, resulting in high productivity and cost-effectiveness for complex shapes. Isostatic pressing uniformly compresses graphite powder from all directions, producing parts with superior density and mechanical strength, ideal for applications demanding high performance and durability. Both methods enhance graphite pet properties but differ in production scale, consistency, and final material characteristics.

Table of Comparison

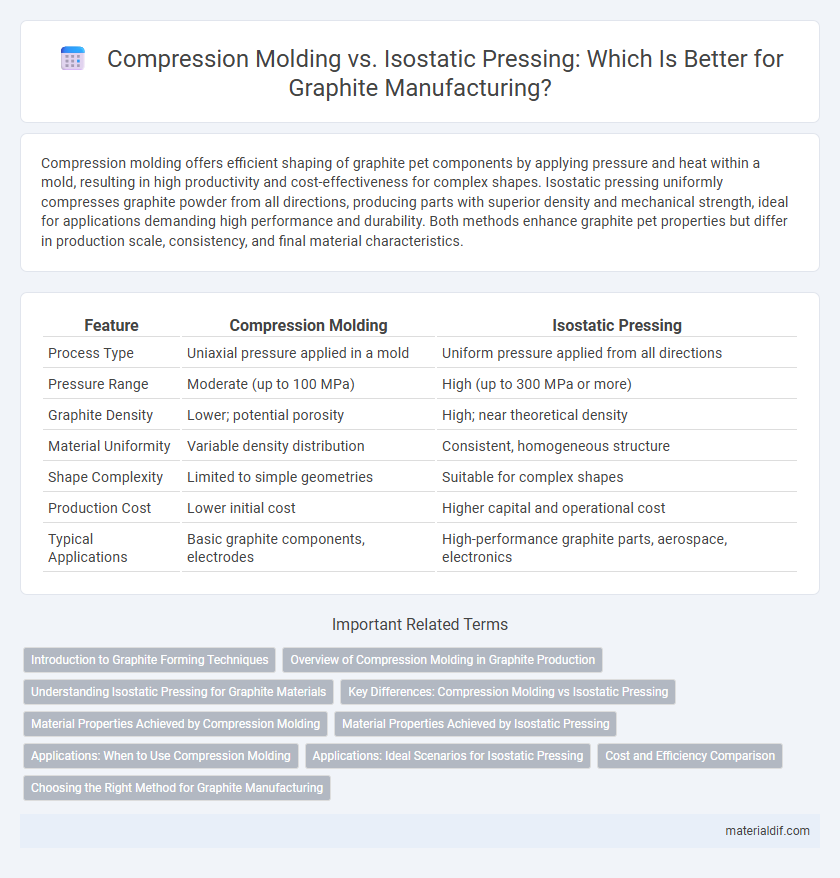

| Feature | Compression Molding | Isostatic Pressing |

|---|---|---|

| Process Type | Uniaxial pressure applied in a mold | Uniform pressure applied from all directions |

| Pressure Range | Moderate (up to 100 MPa) | High (up to 300 MPa or more) |

| Graphite Density | Lower; potential porosity | High; near theoretical density |

| Material Uniformity | Variable density distribution | Consistent, homogeneous structure |

| Shape Complexity | Limited to simple geometries | Suitable for complex shapes |

| Production Cost | Lower initial cost | Higher capital and operational cost |

| Typical Applications | Basic graphite components, electrodes | High-performance graphite parts, aerospace, electronics |

Introduction to Graphite Forming Techniques

Graphite forming techniques include compression molding and isostatic pressing, which shape powdered graphite into solid forms for industrial applications. Compression molding applies unidirectional pressure and heat in a die, ideal for producing large and complex parts with precise dimensions. Isostatic pressing uses uniform pressure from all directions within a fluid medium, resulting in highly dense and homogenous graphite components with superior mechanical properties.

Overview of Compression Molding in Graphite Production

Compression molding in graphite production involves placing powdered graphite material into a heated mold where high pressure is applied to form dense, shaped components. This method offers precise control over the product's density and dimensional accuracy, leading to improved mechanical strength and thermal conductivity. Compared to isostatic pressing, compression molding is commonly used for producing larger, less complex graphite parts with relatively faster cycle times.

Understanding Isostatic Pressing for Graphite Materials

Isostatic pressing applies uniform pressure from all directions, resulting in highly dense and homogenous graphite materials with improved mechanical strength and reduced porosity compared to compression molding. This technique enhances the microstructure consistency of graphite components, making them ideal for high-performance applications such as aerospace and electrical industries. Understanding isostatic pressing benefits is crucial for optimizing graphite's thermal conductivity and durability in advanced manufacturing processes.

Key Differences: Compression Molding vs Isostatic Pressing

Compression molding applies pressure uniaxially to shape graphite, resulting in anisotropic properties and limited geometric complexity. Isostatic pressing exerts uniform pressure from all directions, producing isotropic graphite with enhanced density and more intricate shapes. The key differences include pressure application method, resulting material uniformity, and achievable product complexity.

Material Properties Achieved by Compression Molding

Compression molding of graphite typically results in high-density materials with excellent mechanical strength and enhanced thermal conductivity due to the application of uniaxial pressure during the curing process. This technique produces anisotropic microstructures that contribute to superior wear resistance and structural integrity in high-temperature environments. The controlled pressure and temperature parameters allow for uniform material properties, making compression-molded graphite ideal for electrical contacts and heat exchangers.

Material Properties Achieved by Isostatic Pressing

Isostatic pressing of graphite results in highly uniform density and improved mechanical strength compared to compression molding, due to the simultaneous application of pressure from all directions. This process enhances microstructural homogeneity, reducing porosity and increasing isotropy, which significantly boosts thermal conductivity and electrical performance. The superior densification achieved through isostatic pressing directly leads to better wear resistance and structural integrity in graphite components.

Applications: When to Use Compression Molding

Compression molding is ideal for manufacturing large, complex graphite components with uniform density, commonly used in electrode production for electric arc furnaces and battery anodes. This method excels in applications requiring high mechanical strength and dimensional stability, such as pump seals and valve plates. Compression molding suits scenarios where cost-effective, high-volume production of intricate shapes is essential.

Applications: Ideal Scenarios for Isostatic Pressing

Isostatic pressing excels in producing complex graphite components requiring uniform density and mechanical strength, such as aerospace parts, advanced electronic substrates, and precision tooling. Its ability to apply pressure evenly from all directions makes it ideal for manufacturing intricate shapes with consistent microstructure and minimal porosity. This process is preferred over compression molding when high-performance graphite parts demand superior reliability and intricate design features.

Cost and Efficiency Comparison

Compression molding of graphite offers lower initial equipment costs and faster cycle times, making it more cost-effective for high-volume production runs. Isostatic pressing delivers superior material density and uniformity, resulting in enhanced mechanical properties but at higher operational expenses due to complex equipment and longer processing times. Efficiency gains from isostatic pressing are often balanced by increased costs, while compression molding remains preferred for applications prioritizing speed and lower expenditure.

Choosing the Right Method for Graphite Manufacturing

Choosing the right graphite manufacturing method depends on the desired material properties and application requirements. Compression molding offers high density and superior mechanical strength, making it ideal for large, simple shapes with precise dimensions. Isostatic pressing provides uniform density and excellent anisotropic characteristics, suitable for complex geometries and components requiring enhanced structural consistency.

Compression Molding vs Isostatic Pressing Infographic

materialdif.com

materialdif.com