Spherical graphite offers superior performance in lithium-ion batteries due to its higher purity and consistent particle size, leading to better electrical conductivity and increased energy density compared to flake graphite. Flake graphite, while more abundant and cost-effective, is less uniform and requires extensive processing to achieve similar battery-grade quality. Choosing spherical graphite over flake graphite enhances battery efficiency and longevity, making it the preferred material for high-performance energy storage applications.

Table of Comparison

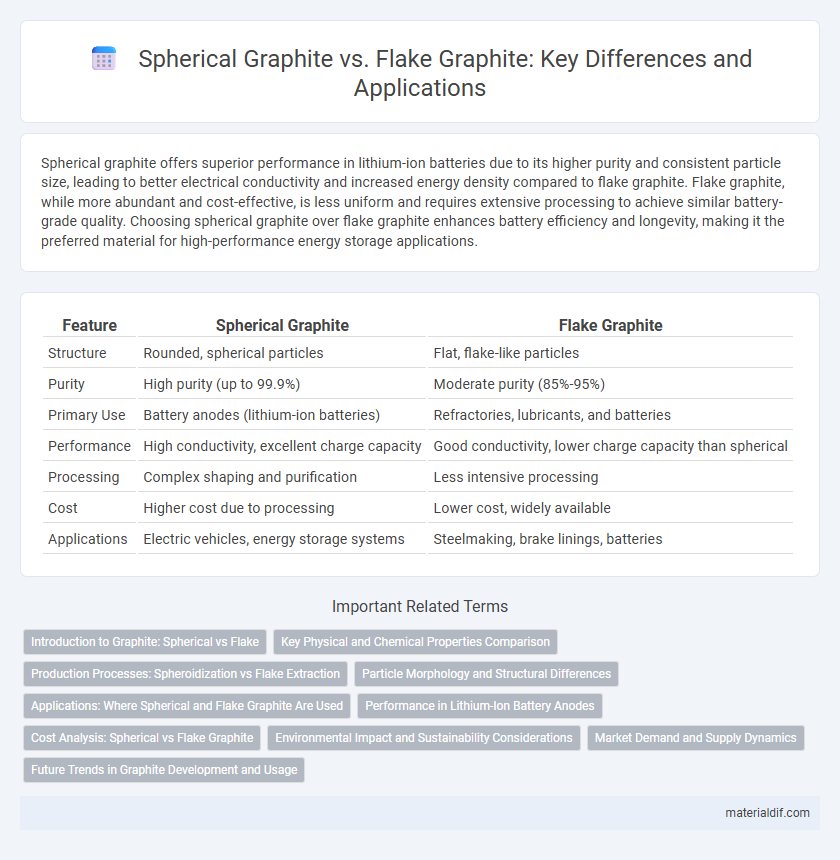

| Feature | Spherical Graphite | Flake Graphite |

|---|---|---|

| Structure | Rounded, spherical particles | Flat, flake-like particles |

| Purity | High purity (up to 99.9%) | Moderate purity (85%-95%) |

| Primary Use | Battery anodes (lithium-ion batteries) | Refractories, lubricants, and batteries |

| Performance | High conductivity, excellent charge capacity | Good conductivity, lower charge capacity than spherical |

| Processing | Complex shaping and purification | Less intensive processing |

| Cost | Higher cost due to processing | Lower cost, widely available |

| Applications | Electric vehicles, energy storage systems | Steelmaking, brake linings, batteries |

Introduction to Graphite: Spherical vs Flake

Spherical graphite consists of small, rounded particles often used in lithium-ion battery anodes for enhanced conductivity and packing density, while flake graphite features flat, plate-like structures commonly employed in refractory materials and lubricants due to its high purity and thermal stability. The distinct physical shapes influence key properties such as surface area, electrical conductivity, and processing applications. Understanding the differences aids in selecting the appropriate graphite type for industries like energy storage, metallurgy, and chemical manufacturing.

Key Physical and Chemical Properties Comparison

Spherical graphite exhibits a highly uniform particle size, excellent electrical conductivity, and superior structural stability compared to flake graphite, making it ideal for lithium-ion battery anodes. Flake graphite, characterized by larger, irregularly shaped particles with higher surface area, offers greater lubricity and thermal conductivity, beneficial for refractory and lubricant applications. Chemically, spherical graphite typically has higher purity and lower ash content, enhancing battery performance, whereas flake graphite contains more impurities like silica or carbonates, influencing its reactivity and processing requirements.

Production Processes: Spheroidization vs Flake Extraction

Spherical graphite production involves the spheroidization process, where natural or synthetic graphite flakes are crushed, purified, and then shaped into uniform spherical particles through heat treatment or chemical vapor deposition. In contrast, flake graphite extraction is primarily achieved by mining graphite ore, followed by mechanical size reduction and flotation to separate high-purity graphite flakes. The spheroidization process enhances the electrochemical performance of spherical graphite for lithium-ion batteries, while flake graphite retains its intrinsic layered structure suitable for refractory and lubricant applications.

Particle Morphology and Structural Differences

Spherical graphite exhibits a uniform, rounded particle morphology that enhances electrode packing density and lithium-ion diffusion efficiency, while flake graphite possesses a flat, layered structure with high aspect ratio particles that provide improved electrical conductivity but lower tap density. Structurally, spherical graphite undergoes graphitization processes that result in more isotropic crystal orientations, optimizing performance in lithium-ion battery anodes. Flake graphite retains its natural crystalline layer arrangements with anisotropic characteristics, which influence its mechanical and electrochemical properties differently than spherical forms.

Applications: Where Spherical and Flake Graphite Are Used

Spherical graphite is primarily used in lithium-ion battery anodes, benefiting from its high purity and excellent electrical conductivity, which enhance battery performance and cycle life. Flake graphite finds applications in refractories, lubricants, and expandable graphite due to its layered structure and thermal stability, making it suitable for heat-resistant materials and fire retardants. The distinct physical forms dictate their specialized uses, with spherical graphite optimized for energy storage and flake graphite for industrial and chemical applications.

Performance in Lithium-Ion Battery Anodes

Spherical graphite offers superior performance in lithium-ion battery anodes due to its high tap density and excellent coulombic efficiency, resulting in enhanced energy density and cycle life. Flake graphite, though abundant and cost-effective, exhibits lower packing density and less uniform particle morphology, which can reduce battery capacity and stability. Optimizing spherical graphite properties such as particle size distribution and surface modification significantly improves anode conductivity and lithium-ion diffusion rates.

Cost Analysis: Spherical vs Flake Graphite

Spherical graphite typically incurs higher production costs than flake graphite due to intensive processing techniques like milling and shaping to achieve uniform particle size and morphology. Flake graphite remains more cost-effective, benefiting from simpler extraction and minimal processing requirements, making it preferred for bulk industrial uses. Despite higher costs, spherical graphite's superior performance in lithium-ion batteries justifies investment in high-purity, battery-grade material for energy storage applications.

Environmental Impact and Sustainability Considerations

Spherical graphite demonstrates lower environmental impact compared to flake graphite due to its more efficient energy usage during processing and higher yield in lithium-ion battery anodes. Flake graphite extraction often involves extensive mining and chemical treatments, leading to greater habitat disruption and higher emissions. Sustainable production of spherical graphite incorporates advanced recycling techniques and cleaner processing methods that reduce waste and minimize carbon footprint.

Market Demand and Supply Dynamics

Spherical graphite dominates the lithium-ion battery anode market due to its superior energy density and charging efficiency, driving higher demand compared to flake graphite, which is primarily used in refractory and lubricant applications. Market supply of spherical graphite is constrained by complex manufacturing processes and high production costs, whereas flake graphite benefits from more abundant deposits and simpler extraction methods. Recent shifts in electric vehicle production are intensifying the demand-supply gap for spherical graphite, pushing prices upward and encouraging investments in synthetic graphite alternatives.

Future Trends in Graphite Development and Usage

Spherical graphite is increasingly favored over flake graphite for lithium-ion battery anodes due to its superior packing density and electrochemical performance, driving innovation in electric vehicle and energy storage technologies. Advances in purification and coating methods are enhancing spherical graphite's conductivity and cycle life, positioning it as a key material in next-generation battery applications. Market trends indicate a shift towards sustainable, high-purity spherical graphite production to meet growing demand from renewable energy sectors.

Spherical Graphite vs Flake Graphite Infographic

materialdif.com

materialdif.com