Fine-grained graphite features smaller, more uniform crystal structures, enhancing strength, machinability, and thermal conductivity, making it ideal for precision applications. Coarse-grained graphite has larger crystals, offering superior electrical conductivity and higher resistance to thermal shock, suited for heavy-duty industrial uses. Choosing between fine-grained and coarse-grained graphite depends on the balance required between mechanical strength and conductivity for specific pet-related applications.

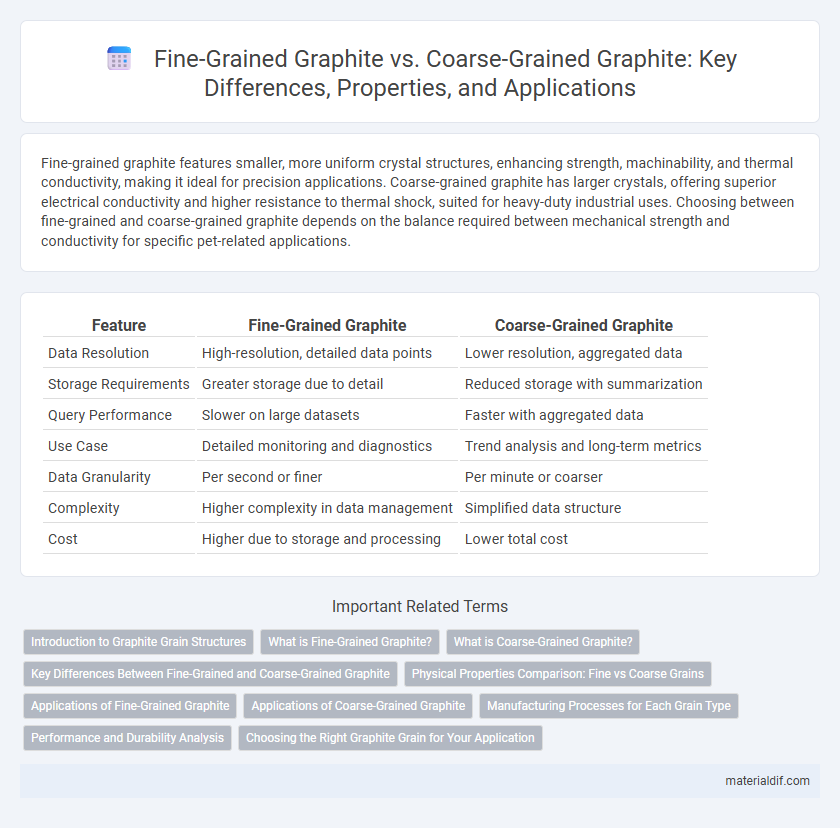

Table of Comparison

| Feature | Fine-Grained Graphite | Coarse-Grained Graphite |

|---|---|---|

| Data Resolution | High-resolution, detailed data points | Lower resolution, aggregated data |

| Storage Requirements | Greater storage due to detail | Reduced storage with summarization |

| Query Performance | Slower on large datasets | Faster with aggregated data |

| Use Case | Detailed monitoring and diagnostics | Trend analysis and long-term metrics |

| Data Granularity | Per second or finer | Per minute or coarser |

| Complexity | Higher complexity in data management | Simplified data structure |

| Cost | Higher due to storage and processing | Lower total cost |

Introduction to Graphite Grain Structures

Fine-grained graphite features small, uniformly distributed grains that enhance mechanical strength and thermal conductivity, making it ideal for precision applications. Coarse-grained graphite contains larger grains, offering improved machinability and lower electrical resistance, suitable for high-temperature and electrical uses. Understanding grain structure differences is essential for optimizing graphite performance in industrial and technological applications.

What is Fine-Grained Graphite?

Fine-grained graphite consists of small, uniform graphite crystals that enhance mechanical strength and thermal conductivity, making it ideal for applications requiring precision and durability. Its fine microstructure allows for better machinability and resistance to thermal shock compared to coarse-grained graphite, which has larger, less uniform crystals. Industries such as aerospace, electronics, and automotive utilize fine-grained graphite for high-performance components that demand consistent material properties and reliability.

What is Coarse-Grained Graphite?

Coarse-grained graphite consists of large, distinct graphite flakes that provide excellent machinability and vibration damping in cast iron applications. This type of graphite structure enhances tensile strength and thermal conductivity compared to fine-grained graphite. Coarse-grained graphite is commonly used in automotive engine blocks and heavy-duty machinery due to its superior mechanical properties and heat dissipation capabilities.

Key Differences Between Fine-Grained and Coarse-Grained Graphite

Fine-grained graphite features smaller, tightly packed crystallites leading to higher strength and better machinability, while coarse-grained graphite contains larger crystals that provide superior thermal conductivity and electrical performance. Fine-grained graphite is preferred for precision components requiring fine detailing, whereas coarse-grained graphite suits applications demanding enhanced heat resistance and structural integrity. The microstructural variations influence their mechanical, electrical, and thermal properties, dictating suitable industrial uses such as aerospace for fine-grained and high-temperature electrodes for coarse-grained graphite.

Physical Properties Comparison: Fine vs Coarse Grains

Fine-grained graphite exhibits higher strength, improved wear resistance, and enhanced thermal conductivity compared to coarse-grained graphite due to its smaller grain size and increased grain boundary area. Coarse-grained graphite generally offers better machinability and electrical conductivity but demonstrates lower mechanical strength and reduced thermal shock resistance. The grain size significantly influences properties such as density, hardness, and porosity, making fine-grained graphite suitable for applications requiring precision and durability.

Applications of Fine-Grained Graphite

Fine-grained graphite, characterized by its small and uniform crystal structure, is extensively used in high-precision applications such as electrodes for batteries, aerospace components, and advanced electronics due to its superior mechanical strength and thermal conductivity. Its fine particle size enables enhanced machinability and improved performance in applications requiring high wear resistance and electrical conductivity. This makes fine-grained graphite ideal for precision tooling, sealing elements, and components in nuclear reactors.

Applications of Coarse-Grained Graphite

Coarse-grained graphite is widely used in electrode manufacturing for electric arc furnaces and nuclear reactors due to its superior thermal conductivity and high mechanical strength. Its large crystal size enhances resistance to thermal shock and oxidation, making it ideal for high-temperature industrial processes. Additionally, coarse-grained graphite serves critical roles in aerospace components and high-performance batteries, where robustness and efficient heat dissipation are essential.

Manufacturing Processes for Each Grain Type

Fine-grained graphite is produced through high-pressure, high-temperature sintering of fine graphite powders, resulting in a dense microstructure with uniform grain distribution that enhances mechanical strength and thermal conductivity. Coarse-grained graphite manufacturing involves controlled growth of larger crystallites via extended heat treatment and graphitization cycles, yielding a structure with fewer grain boundaries for improved electrical conductivity and machinability. These distinct processes tailor microstructural properties to specific industrial applications, optimizing performance parameters such as durability and thermal stability.

Performance and Durability Analysis

Fine-grained graphite exhibits superior mechanical strength and thermal conductivity due to its smaller grain size, enhancing performance in high-stress applications. Coarse-grained graphite, while less robust, offers improved durability in high-temperature environments by better accommodating thermal expansion and reducing crack propagation. Performance optimization depends on balancing grain size to meet specific durability requirements, with fine-grained variants excelling in precision components and coarse-grained forms favored for heavy-duty industrial uses.

Choosing the Right Graphite Grain for Your Application

Fine-grained graphite offers superior strength, thermal shock resistance, and precision, making it ideal for high-performance applications such as aerospace and electronics. Coarse-grained graphite, with its larger grain size, excels in thermal conductivity and machinability, suited for metallurgical and chemical industries. Selecting the appropriate graphite grain size depends on balancing factors like mechanical strength, thermal properties, and specific application requirements to optimize performance and cost-efficiency.

Fine-Grained Graphite vs Coarse-Grained Graphite Infographic

materialdif.com

materialdif.com