Oxidized graphite features oxygen-containing functional groups that enhance its hydrophilicity and chemical reactivity, making it ideal for applications in catalysis and composite materials. Non-oxidized graphite retains its pristine layered structure, offering superior electrical conductivity and thermal stability, which are essential for electronic devices and heat management. The choice between oxidized and non-oxidized graphite depends on the balance between surface functionality and intrinsic physical properties required for specific industrial uses.

Table of Comparison

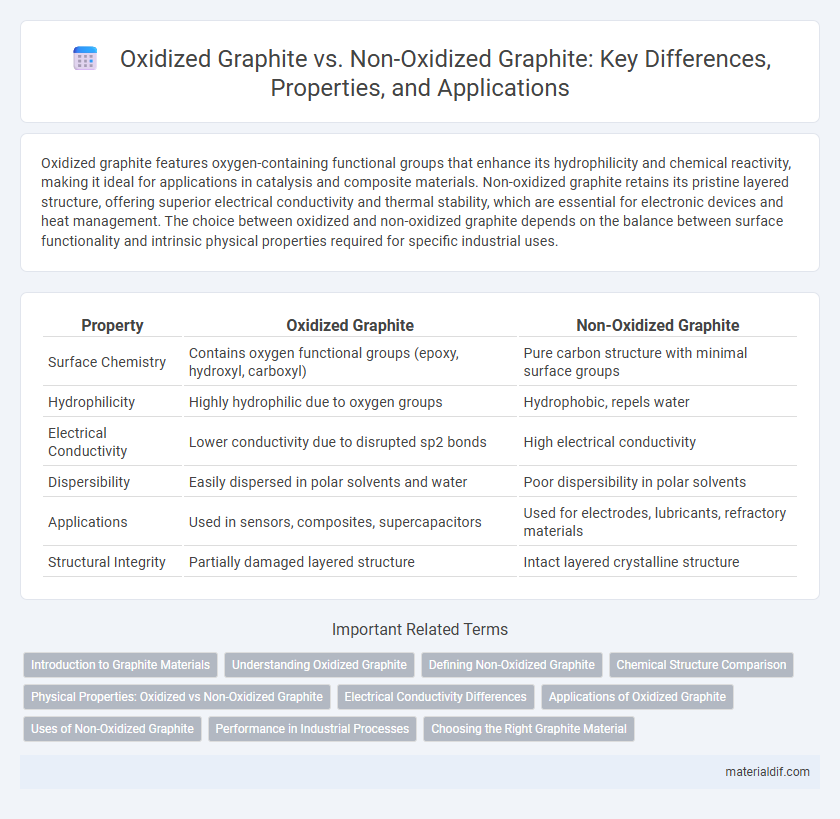

| Property | Oxidized Graphite | Non-Oxidized Graphite |

|---|---|---|

| Surface Chemistry | Contains oxygen functional groups (epoxy, hydroxyl, carboxyl) | Pure carbon structure with minimal surface groups |

| Hydrophilicity | Highly hydrophilic due to oxygen groups | Hydrophobic, repels water |

| Electrical Conductivity | Lower conductivity due to disrupted sp2 bonds | High electrical conductivity |

| Dispersibility | Easily dispersed in polar solvents and water | Poor dispersibility in polar solvents |

| Applications | Used in sensors, composites, supercapacitors | Used for electrodes, lubricants, refractory materials |

| Structural Integrity | Partially damaged layered structure | Intact layered crystalline structure |

Introduction to Graphite Materials

Oxidized graphite features surface oxygen-containing functional groups that enhance its hydrophilicity and dispersion in aqueous media, making it suitable for applications in energy storage and catalysis. Non-oxidized graphite retains its pristine layered structure with high electrical conductivity and thermal stability, ideal for electrodes and lubricants. The choice between oxidized and non-oxidized graphite depends on specific material requirements such as conductivity, surface chemistry, and interaction with other components.

Understanding Oxidized Graphite

Oxidized graphite, also known as graphite oxide, contains oxygen functional groups such as epoxides, hydroxyls, and carboxyls attached to its basal planes and edges, which drastically alter its chemical reactivity and hydrophilicity compared to non-oxidized graphite. This oxidation process introduces defects and disorder into the graphite lattice, enhancing its dispersibility in water and enabling further chemical modifications essential for composite materials and graphene oxide production. Understanding the structural and chemical differences between oxidized and non-oxidized graphite is critical for applications in energy storage, sensors, and catalysis where surface chemistry plays a pivotal role.

Defining Non-Oxidized Graphite

Non-oxidized graphite is a form of graphite that retains its original crystalline structure without undergoing oxidative treatment, preserving its natural electrical conductivity and mechanical strength. Unlike oxidized graphite, it lacks oxygen-containing functional groups, resulting in lower hydrophilicity and improved stability in high-temperature environments. This form is crucial for applications requiring high thermal conductivity and minimal chemical reactivity, such as in electrodes, lubricants, and composite materials.

Chemical Structure Comparison

Oxidized graphite, commonly known as graphite oxide, contains oxygen-containing functional groups such as hydroxyl, epoxy, and carboxyl groups attached to its basal planes and edges, disrupting the sp2 hybridized carbon lattice and increasing interlayer spacing. Non-oxidized graphite maintains a pristine hexagonal arrangement of sp2 bonded carbon atoms with strong van der Waals forces between layers, preserving high electrical conductivity and structural integrity. The introduction of oxygen groups in oxidized graphite imparts hydrophilicity and chemical reactivity, contrasting with the hydrophobic and chemically inert nature of non-oxidized graphite.

Physical Properties: Oxidized vs Non-Oxidized Graphite

Oxidized graphite exhibits increased hydrophilicity and a higher degree of surface roughness compared to non-oxidized graphite, resulting from oxygen-containing functional groups introduced during oxidation. Non-oxidized graphite maintains excellent electrical conductivity and structural integrity with a smooth layered morphology, whereas oxidized graphite shows reduced conductivity due to disruption of its crystalline lattice. The enhanced interlayer spacing and improved dispersibility of oxidized graphite contrast with the denser, more rigid structure of non-oxidized graphite, impacting their respective mechanical and chemical performances.

Electrical Conductivity Differences

Oxidized graphite exhibits significantly reduced electrical conductivity compared to non-oxidized graphite due to the introduction of oxygen-containing functional groups that disrupt the sp2 bonding network. Non-oxidized graphite maintains a highly ordered crystalline structure, allowing for efficient electron delocalization and superior conductive properties. The increased defects and layer separation in oxidized graphite impede electron mobility, resulting in diminished electrical performance.

Applications of Oxidized Graphite

Oxidized graphite, commonly known as graphite oxide, exhibits enhanced hydrophilicity and chemical reactivity compared to non-oxidized graphite, making it ideal for applications such as water purification, energy storage, and composite materials. Its increased surface functional groups allow for effective adsorption of heavy metals and organic contaminants in wastewater treatment processes. In energy storage, oxidized graphite improves electrode performance in supercapacitors and lithium-ion batteries due to its superior electrical conductivity and structural stability.

Uses of Non-Oxidized Graphite

Non-oxidized graphite maintains its crystalline structure, making it highly effective for applications requiring excellent electrical conductivity and thermal resistance. It is commonly used in electrodes, batteries, and lubricants due to its stable chemical properties and superior mechanical strength. Industrial sectors utilize non-oxidized graphite in manufacturing refractory materials and high-performance brake linings.

Performance in Industrial Processes

Oxidized graphite exhibits enhanced reactivity and greater chemical stability, improving its performance in catalytic and lubrication applications within industrial processes. Non-oxidized graphite maintains superior electrical and thermal conductivity, making it ideal for high-temperature environments and electrical contacts. The choice between oxidized and non-oxidized graphite depends on the specific industrial process requirements, balancing surface activity and conductivity for optimal efficiency.

Choosing the Right Graphite Material

Oxidized graphite exhibits enhanced hydrophilicity and greater chemical reactivity, making it ideal for applications requiring improved dispersibility and surface functionalization, such as in composites or sensors. Non-oxidized graphite retains superior electrical conductivity and thermal stability, suited for electrodes, heat sinks, and lubrication purposes where minimal chemical intervention is critical. Selecting between oxidized and non-oxidized graphite depends on balancing the need for surface modification against maintaining intrinsic conductive and mechanical properties in the intended application.

Oxidized Graphite vs Non-Oxidized Graphite Infographic

materialdif.com

materialdif.com