Graphite felt offers superior thermal conductivity and oxidation resistance compared to carbon felt, making it ideal for high-temperature applications like fuel cells and thermal insulation. Carbon felt, while typically more affordable, exhibits lower durability under extreme heat and chemical exposure. Selecting between graphite felt and carbon felt depends on the specific requirements for performance, lifespan, and cost efficiency in industrial or aerospace environments.

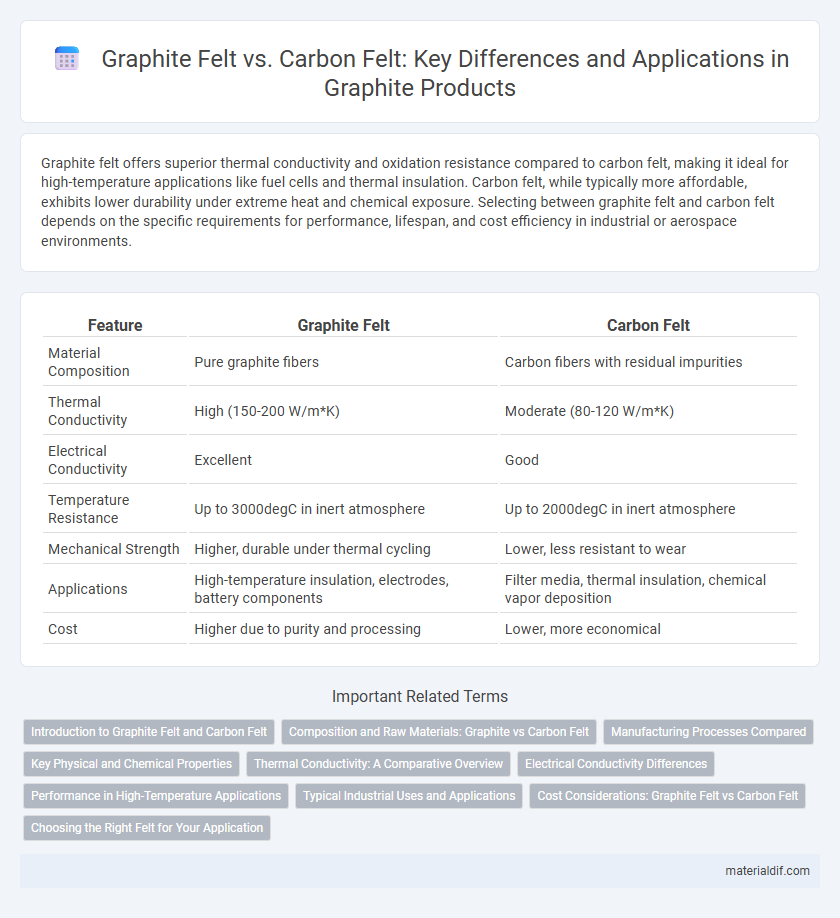

Table of Comparison

| Feature | Graphite Felt | Carbon Felt |

|---|---|---|

| Material Composition | Pure graphite fibers | Carbon fibers with residual impurities |

| Thermal Conductivity | High (150-200 W/m*K) | Moderate (80-120 W/m*K) |

| Electrical Conductivity | Excellent | Good |

| Temperature Resistance | Up to 3000degC in inert atmosphere | Up to 2000degC in inert atmosphere |

| Mechanical Strength | Higher, durable under thermal cycling | Lower, less resistant to wear |

| Applications | High-temperature insulation, electrodes, battery components | Filter media, thermal insulation, chemical vapor deposition |

| Cost | Higher due to purity and processing | Lower, more economical |

Introduction to Graphite Felt and Carbon Felt

Graphite felt is a porous material made from graphite fibers, known for its high thermal conductivity, chemical stability, and resistance to thermal shock, making it ideal for high-temperature insulation and energy storage applications. Carbon felt, composed of carbon fibers, offers excellent electrical conductivity, chemical inertness, and mechanical strength, often used in fuel cells, filtration, and battery electrodes. Both materials provide lightweight, durable solutions, but graphite felt excels in thermal management, while carbon felt is preferred for electrical and electrochemical uses.

Composition and Raw Materials: Graphite vs Carbon Felt

Graphite felt is primarily composed of high-purity graphite fibers derived from petroleum coke, offering excellent thermal conductivity and oxidation resistance. Carbon felt consists of amorphous carbon fibers produced through the carbonization of polyacrylonitrile (PAN) or cellulose, resulting in a more porous structure with lower thermal stability. The key difference lies in graphite felt's crystalline graphite structure versus carbon felt's less ordered carbon matrix, directly impacting their performance in high-temperature applications.

Manufacturing Processes Compared

Graphite felt is manufactured through the graphitization of carbon felt at high temperatures, enhancing its electrical conductivity and thermal stability for advanced industrial applications. Carbon felt is typically produced by needling or weaving carbon fibers into mats, then stabilized via pyrolysis to maintain structural integrity. The graphitization step distinguishes graphite felt by increasing crystallinity and reducing impurities, resulting in superior mechanical and thermal properties compared to carbon felt.

Key Physical and Chemical Properties

Graphite felt exhibits superior electrical conductivity and thermal stability compared to carbon felt, making it ideal for high-temperature industrial applications. Its crystalline structure provides enhanced oxidation resistance and mechanical strength, whereas carbon felt is more porous and has lower density, resulting in better flexibility but reduced durability. Chemical inertness in graphite felt allows it to withstand aggressive environments, distinguishing it from carbon felt which is more reactive and less suited for corrosive conditions.

Thermal Conductivity: A Comparative Overview

Graphite felt exhibits significantly higher thermal conductivity, typically ranging from 100 to 160 W/m*K, compared to carbon felt, which generally falls between 30 and 80 W/m*K. This enhanced thermal performance makes graphite felt more suitable for high-temperature applications like heat exchangers and thermal insulation in industrial furnaces. The anisotropic structure of graphite felt contributes to efficient heat transfer along specific directions, whereas carbon felt's more isotropic composition results in comparatively lower thermal conductivity.

Electrical Conductivity Differences

Graphite felt exhibits higher electrical conductivity compared to carbon felt due to its more ordered crystalline structure and fewer defects. The enhanced conductivity in graphite felt makes it ideal for applications in fuel cells and electrodes where efficient electron transfer is critical. Carbon felt, by contrast, has lower conductivity but offers greater flexibility and surface area for catalytic processes.

Performance in High-Temperature Applications

Graphite felt exhibits superior thermal stability and oxidation resistance compared to carbon felt, making it ideal for high-temperature applications exceeding 2500degC. Its enhanced structural integrity under extreme heat maintains consistent electrical conductivity and dimensional stability, outperforming carbon felt, which tends to degrade faster under such conditions. Graphite felt's high purity and low reactivity also contribute to better performance in environments like aerospace, metallurgy, and high-temperature insulation.

Typical Industrial Uses and Applications

Graphite felt is primarily used in high-temperature insulation for metallurgy, aerospace thermal protection, and battery electrodes due to its superior thermal conductivity and chemical resistance. Carbon felt finds typical industrial applications in fuel cells, electric furnaces, and filtration systems, benefiting from its excellent electrical conductivity and mechanical strength. Both materials serve critical roles in industries requiring durable, heat-resistant, and conductive materials, with graphite felt favored for thermal insulation and carbon felt preferred for electrochemical and filtration uses.

Cost Considerations: Graphite Felt vs Carbon Felt

Graphite felt typically incurs higher costs due to its advanced manufacturing process and superior thermal stability compared to carbon felt. Carbon felt offers a more budget-friendly option, though it may lack the enhanced durability and oxidation resistance found in graphite felt. When selecting materials for thermal insulation or filtration, the cost-performance balance between graphite felt and carbon felt should be carefully evaluated.

Choosing the Right Felt for Your Application

Graphite felt offers superior thermal conductivity and chemical resistance, making it ideal for high-temperature industrial processes such as filtration and insulation. Carbon felt provides excellent electrical conductivity and mechanical strength, suited for applications in electrode fabrication and energy storage systems. Selecting the right felt depends on operating conditions, required durability, and specific properties like thermal performance or electrical conductivity.

Graphite Felt vs Carbon Felt Infographic

materialdif.com

materialdif.com