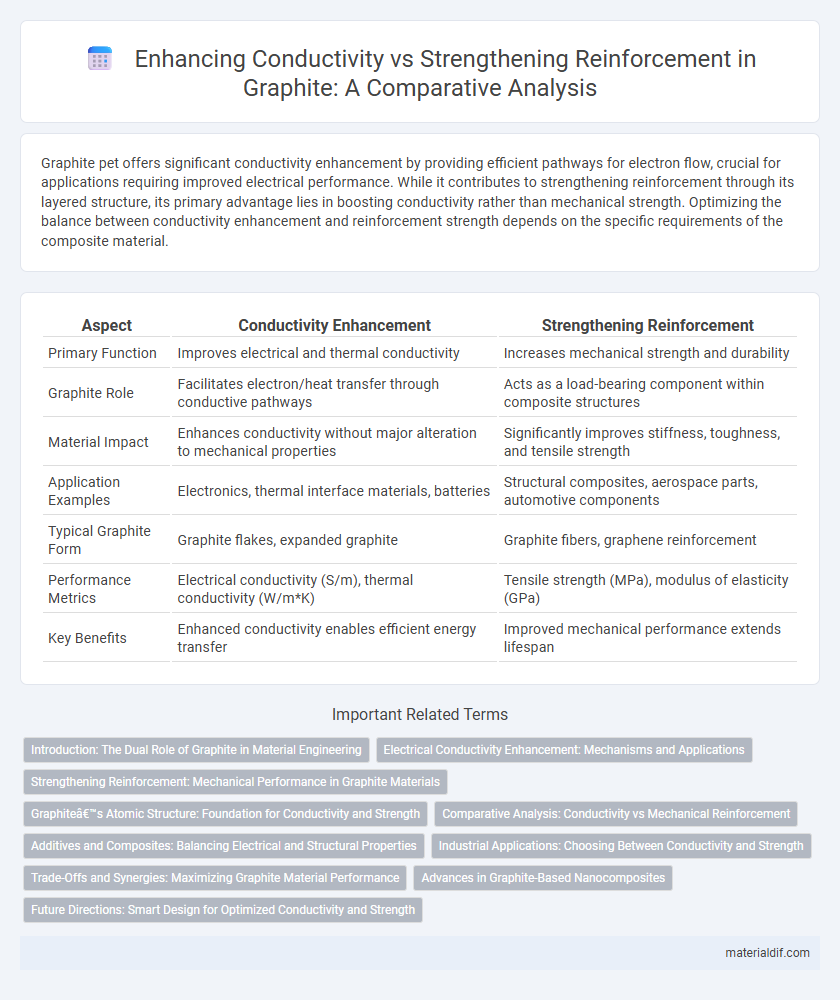

Graphite pet offers significant conductivity enhancement by providing efficient pathways for electron flow, crucial for applications requiring improved electrical performance. While it contributes to strengthening reinforcement through its layered structure, its primary advantage lies in boosting conductivity rather than mechanical strength. Optimizing the balance between conductivity enhancement and reinforcement strength depends on the specific requirements of the composite material.

Table of Comparison

| Aspect | Conductivity Enhancement | Strengthening Reinforcement |

|---|---|---|

| Primary Function | Improves electrical and thermal conductivity | Increases mechanical strength and durability |

| Graphite Role | Facilitates electron/heat transfer through conductive pathways | Acts as a load-bearing component within composite structures |

| Material Impact | Enhances conductivity without major alteration to mechanical properties | Significantly improves stiffness, toughness, and tensile strength |

| Application Examples | Electronics, thermal interface materials, batteries | Structural composites, aerospace parts, automotive components |

| Typical Graphite Form | Graphite flakes, expanded graphite | Graphite fibers, graphene reinforcement |

| Performance Metrics | Electrical conductivity (S/m), thermal conductivity (W/m*K) | Tensile strength (MPa), modulus of elasticity (GPa) |

| Key Benefits | Enhanced conductivity enables efficient energy transfer | Improved mechanical performance extends lifespan |

Introduction: The Dual Role of Graphite in Material Engineering

Graphite serves a dual role in material engineering by simultaneously enhancing electrical conductivity and providing mechanical reinforcement. Its unique layered structure allows electrons to flow easily, improving conductivity, while its strong covalent bonding between carbon atoms contributes to material strength. Balancing these properties is critical for optimizing composite performance in applications such as aerospace and electronics.

Electrical Conductivity Enhancement: Mechanisms and Applications

Electrical conductivity enhancement in graphite is primarily achieved through the optimization of its crystalline structure, promoting electron mobility along the sp2-bonded carbon layers. Defect engineering and controlled doping with heteroatoms like nitrogen or boron introduce charge carriers and reduce electron scattering, thereby significantly increasing conductivity. These mechanisms enable critical applications in advanced energy storage, electromagnetic interference shielding, and high-performance electronics where superior electrical conduction combined with material robustness is essential.

Strengthening Reinforcement: Mechanical Performance in Graphite Materials

Strengthening reinforcement in graphite materials significantly improves mechanical performance by increasing tensile strength, fracture toughness, and wear resistance. Incorporating carbon fibers or ceramic particles into the graphite matrix enhances load transfer efficiency and reduces crack propagation under stress. This reinforcement approach optimizes durability and structural integrity, making graphite composites suitable for high-stress engineering applications.

Graphite’s Atomic Structure: Foundation for Conductivity and Strength

Graphite's atomic structure features layers of carbon atoms arranged in a hexagonal lattice, promoting high electrical conductivity due to delocalized electrons within these planes. This layered configuration allows for effective conductivity enhancement as electrons can move freely along the planes, while the weaker interlayer bonds contribute to mechanical flexibility rather than strength. Strengthening reinforcement in graphite relies on modifying interlayer interactions or incorporating other materials to improve load transfer and mechanical robustness without compromising its inherent conductive properties.

Comparative Analysis: Conductivity vs Mechanical Reinforcement

Graphite exhibits superior electrical conductivity due to its delocalized pi-electrons within the hexagonal carbon layers, making it an ideal material for conductivity enhancement applications. In contrast, mechanical reinforcement benefits from the inherent high tensile strength and stiffness of graphite flakes or fibers, which improve composite strength without significantly altering electrical properties. Comparative analysis reveals that optimizing graphite for conductivity often requires maintaining its structural continuity, while maximizing mechanical reinforcement may involve functionalization or hybridization that can compromise electrical pathways.

Additives and Composites: Balancing Electrical and Structural Properties

Graphite-based composites achieve a critical balance between conductivity enhancement and strengthening reinforcement by integrating conductive additives such as carbon nanotubes, graphene, or metallic nanoparticles. These additives significantly improve the electrical conductivity while simultaneously contributing to mechanical strength through effective load transfer and crack deflection. Optimizing the concentration and dispersion of these additives in matrices like epoxy or polymer composites ensures enhanced electrical pathways without compromising the composite's structural integrity.

Industrial Applications: Choosing Between Conductivity and Strength

Graphite's conductivity enhancement is critical in applications such as electrodes, thermal management systems, and electrical contacts where high electrical and thermal conductivity ensures optimal performance. Strengthening reinforcement with graphite composites is preferred in structural components of aerospace, automotive, and sports equipment industries to achieve lightweight durability and mechanical resilience. Industrial applications must balance these priorities by selecting graphite materials tailored for either superior conductivity or mechanical strength, depending on specific operational demands.

Trade-Offs and Synergies: Maximizing Graphite Material Performance

Enhancing conductivity in graphite often requires structural modifications that may compromise mechanical strength, highlighting a fundamental trade-off between electrical performance and reinforcement. Optimizing graphite's microstructure through controlled defect engineering and tailored interlayer bonding can create synergies, balancing increased electron mobility with improved load-bearing capacity. Advanced composite designs leveraging nanoscale reinforcements enable simultaneous conductivity enhancement and mechanical strengthening, maximizing overall material performance for demanding applications.

Advances in Graphite-Based Nanocomposites

Graphite-based nanocomposites exhibit significant advancements in balancing conductivity enhancement and strengthening reinforcement through the incorporation of nanoscale fillers such as graphene nanoplatelets and carbon nanotubes, which improve electrical conductivity by up to 50% while simultaneously increasing tensile strength by 30-40%. Functionalization techniques at the nanoscale enable improved interfacial bonding between graphite matrices and reinforcing agents, resulting in synergistic effects that optimize both mechanical performance and electrical properties. Recent studies demonstrate that tailoring filler dispersion and alignment within the composite matrix significantly enhances electron transport pathways and load transfer efficiency, advancing applications in flexible electronics and structural materials.

Future Directions: Smart Design for Optimized Conductivity and Strength

Future advancements in graphite-based materials will emphasize smart design techniques integrating nanostructured additives to simultaneously enhance electrical conductivity and mechanical strength. Leveraging machine learning algorithms to predict optimal composite formulations can accelerate the development of graphite reinforcements with tailored multifunctional properties. Emerging approaches focus on hierarchical architectures combining graphene layers and carbon nanotubes to create adaptive materials balancing conductivity and durability for high-performance applications.

Conductivity Enhancement vs Strengthening Reinforcement Infographic

materialdif.com

materialdif.com