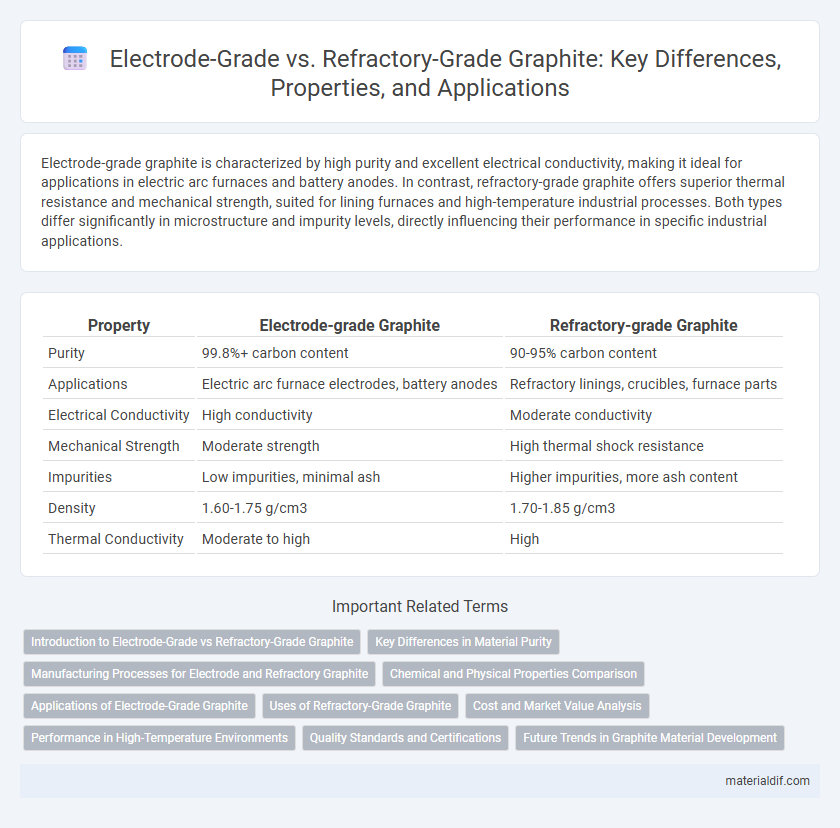

Electrode-grade graphite is characterized by high purity and excellent electrical conductivity, making it ideal for applications in electric arc furnaces and battery anodes. In contrast, refractory-grade graphite offers superior thermal resistance and mechanical strength, suited for lining furnaces and high-temperature industrial processes. Both types differ significantly in microstructure and impurity levels, directly influencing their performance in specific industrial applications.

Table of Comparison

| Property | Electrode-grade Graphite | Refractory-grade Graphite |

|---|---|---|

| Purity | 99.8%+ carbon content | 90-95% carbon content |

| Applications | Electric arc furnace electrodes, battery anodes | Refractory linings, crucibles, furnace parts |

| Electrical Conductivity | High conductivity | Moderate conductivity |

| Mechanical Strength | Moderate strength | High thermal shock resistance |

| Impurities | Low impurities, minimal ash | Higher impurities, more ash content |

| Density | 1.60-1.75 g/cm3 | 1.70-1.85 g/cm3 |

| Thermal Conductivity | Moderate to high | High |

Introduction to Electrode-Grade vs Refractory-Grade Graphite

Electrode-grade graphite exhibits high purity, low ash content, and excellent electrical conductivity, making it ideal for manufacturing electrodes in electric arc furnaces. Refractory-grade graphite is characterized by superior thermal resistance and chemical stability, essential for lining furnaces and other high-temperature industrial applications. The distinct physical and chemical properties differentiate their suitability, with electrode-grade focused on conductivity and refractory-grade emphasizing durability under extreme heat.

Key Differences in Material Purity

Electrode-grade graphite features extremely high purity levels, typically exceeding 99.9% carbon content, making it ideal for applications requiring excellent electrical conductivity and minimal impurities. Refractory-grade graphite contains lower purity, often around 85-98% carbon, which suits heat-resistant applications but limits its electrical performance. The difference in material purity directly impacts the performance characteristics, with electrode-grade graphite excelling in battery anodes and electrical equipment, while refractory-grade is optimized for high-temperature furnace linings.

Manufacturing Processes for Electrode and Refractory Graphite

Electrode-grade graphite is manufactured through a high-purity process involving petroleum coke and coal tar pitch, followed by baking, impregnation, and graphitization at temperatures exceeding 2500degC to achieve optimal electrical conductivity and mechanical strength for use in electric arc furnaces. Refractory-grade graphite is produced by carbonizing and graphitizing natural and synthetic graphite under slightly lower temperatures, focusing on thermal resistance and structural integrity for high-temperature furnace linings and crucibles. The manufacturing differentiation lies in the raw material selection, impurity control, and thermal treatment parameters tailored to meet the electrical and thermal performance requirements of each graphite grade.

Chemical and Physical Properties Comparison

Electrode-grade graphite exhibits high purity levels above 99.8% carbon with low ash content, ensuring excellent electrical conductivity and thermal stability crucial for electric arc furnace electrodes. Refractory-grade graphite contains slightly lower carbon purity, typically around 98-99%, with higher impurities that affect its thermal shock resistance but provides superior mechanical strength for high-temperature furnace linings. The physical structure of electrode-grade graphite features fine grain size and high density to optimize electrical performance, while refractory-grade graphite prioritizes coarse grains and porosity control to withstand abrasive wear and chemical corrosion in harsh metallurgical environments.

Applications of Electrode-Grade Graphite

Electrode-grade graphite is primarily used in the manufacturing of electrodes for electric arc furnaces in steel production due to its high purity, excellent electrical conductivity, and superior thermal resistance. It enables efficient and reliable performance in aluminum smelting, battery anodes, and electrolytic cells where consistent electrical properties and chemical stability are essential. Unlike refractory-grade graphite, which is optimized for resistance to high-temperature corrosion and thermal shock in furnace linings, electrode-grade graphite is tailored for applications demanding high electrical conductivity and minimal impurities.

Uses of Refractory-Grade Graphite

Refractory-grade graphite is primarily used in high-temperature industrial applications such as furnace linings, thermal insulation, and crucibles due to its excellent thermal stability and resistance to oxidation. This type of graphite is essential in steel-making processes, as it can withstand extreme heat and corrosive environments without degrading. Its ability to maintain mechanical strength at elevated temperatures makes refractory-grade graphite vital for manufacturing components in metallurgy and chemical industries.

Cost and Market Value Analysis

Electrode-grade graphite commands higher market value due to its superior purity, electrical conductivity, and mechanical strength, essential for steelmaking and battery applications, translating to a premium cost compared to refractory-grade graphite. Refractory-grade graphite, utilized primarily for furnace linings and thermal insulation, has lower production requirements and chemical specifications, resulting in a significantly reduced cost structure and broader market accessibility. Market trends indicate steady demand growth for electrode-grade graphite driven by electric vehicle battery expansion, whereas refractory-grade graphite faces stable but limited market growth tied to traditional industrial sectors.

Performance in High-Temperature Environments

Electrode-grade graphite exhibits superior electrical conductivity and structural integrity at temperatures exceeding 3000degC, making it ideal for use in electric arc furnaces and other high-temperature industrial applications. Refractory-grade graphite, while also resistant to high temperatures, offers enhanced thermal shock resistance and mechanical strength crucial for furnace linings and crucibles operating under fluctuating thermal loads. Electrode-grade graphite maintains stable performance under continuous electrical and thermal stress, whereas refractory-grade graphite is optimized for durability under cyclic thermal conditions.

Quality Standards and Certifications

Electrode-grade graphite meets stringent quality standards such as ASTM D417 and ISO 9001 certifications, ensuring high purity, electrical conductivity, and mechanical strength essential for electric arc furnace electrodes. Refractory-grade graphite adheres to different criteria focused on thermal resistance and durability, complying with standards like ASTM C552 and ISO 14001 for environmental management. Both grades require rigorous testing for particle size, ash content, and conductivity, but electrode-grade graphite demands superior consistency to withstand extreme conditions in steelmaking.

Future Trends in Graphite Material Development

Electrode-grade graphite exhibits significant advancements due to its critical role in electric arc furnace steelmaking and emerging energy storage applications. Future trends emphasize enhancing purity, electrical conductivity, and structural uniformity to meet increasing demands in lithium-ion batteries and clean energy technologies. Conversely, refractory-grade graphite development focuses on improving thermal resistance and mechanical strength to withstand extreme conditions in high-temperature industrial furnaces, signaling a parallel evolution aligned with stringent industry standards and sustainability goals.

Electrode-grade Graphite vs Refractory-grade Graphite Infographic

materialdif.com

materialdif.com