Synthetic graphite production offers consistent quality and purity levels, enabling precise control over material properties compared to natural mining, which often results in variable composition due to geological differences. While natural graphite mining can lead to environmental degradation and supply chain uncertainties, synthetic graphite manufacturing relies on industrial processes that reduce impurities and improve structural uniformity. Advances in synthetic activity thus provide scalable and sustainable graphite solutions ideal for high-performance applications such as batteries and electronics.

Table of Comparison

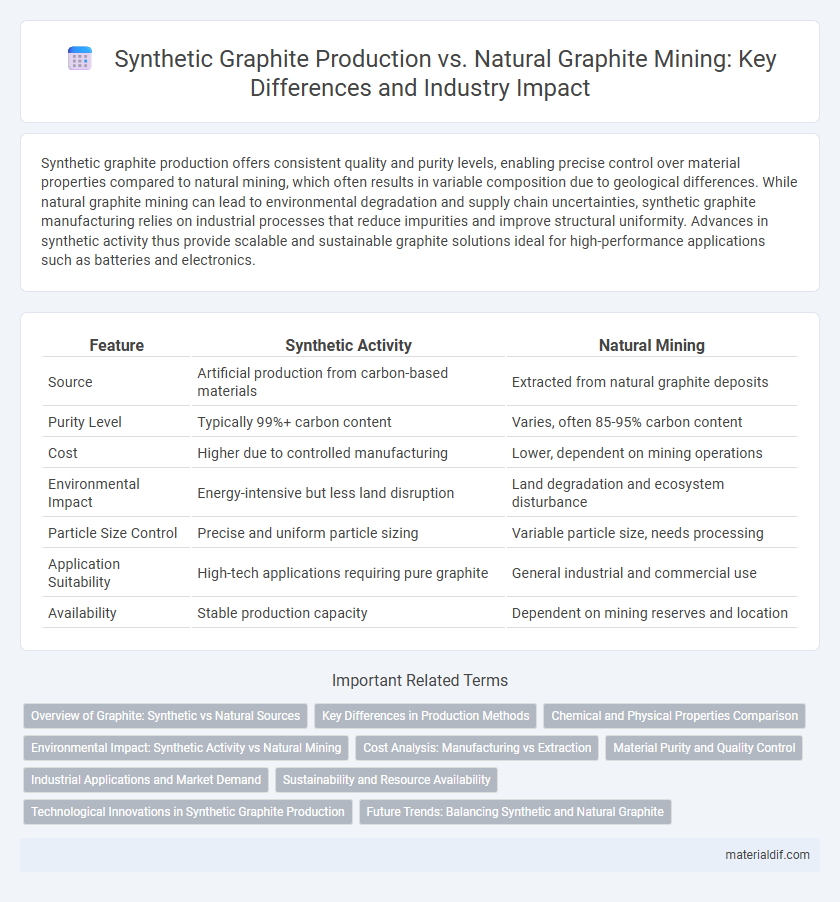

| Feature | Synthetic Activity | Natural Mining |

|---|---|---|

| Source | Artificial production from carbon-based materials | Extracted from natural graphite deposits |

| Purity Level | Typically 99%+ carbon content | Varies, often 85-95% carbon content |

| Cost | Higher due to controlled manufacturing | Lower, dependent on mining operations |

| Environmental Impact | Energy-intensive but less land disruption | Land degradation and ecosystem disturbance |

| Particle Size Control | Precise and uniform particle sizing | Variable particle size, needs processing |

| Application Suitability | High-tech applications requiring pure graphite | General industrial and commercial use |

| Availability | Stable production capacity | Dependent on mining reserves and location |

Overview of Graphite: Synthetic vs Natural Sources

Graphite is sourced from both natural mining and synthetic production, each offering distinct advantages in purity and application. Natural graphite, extracted through mining, is abundant but often contains impurities requiring additional processing, making it suitable for traditional uses like refractory materials and lubricants. Synthetic graphite, produced via high-temperature treatment of carbon-rich precursors, provides superior purity and consistent quality, making it essential for advanced technologies such as lithium-ion batteries and electric vehicle components.

Key Differences in Production Methods

Synthetic graphite is produced through high-temperature treatment of carbon-rich precursors in a controlled environment, enabling tailored purity and structural uniformity, while natural graphite is mined directly from metamorphic rock deposits, requiring extensive purification to remove impurities. The synthetic process involves precise control over temperature, duration, and atmosphere to achieve specific crystalline structures, contrasting with the variable composition and quality inherent in natural graphite extraction. Production methods for synthetic graphite offer scalability and consistency, whereas natural mining depends on geographical availability and involves significant environmental disturbance.

Chemical and Physical Properties Comparison

Synthetic graphite exhibits higher purity levels, improved electrical conductivity, and greater structural uniformity compared to natural graphite, which often contains impurities like quartz and mica. Natural graphite possesses variable crystalline structures, resulting in inconsistent thermal stability and mechanical strength, whereas synthetic graphite shows enhanced density and consistent hardness due to controlled manufacturing processes. Chemical resistance is generally superior in synthetic graphite, making it more suitable for high-temperature and corrosive environments than natural graphite.

Environmental Impact: Synthetic Activity vs Natural Mining

Synthetic graphite production generally results in higher energy consumption and greenhouse gas emissions compared to natural graphite mining, due to its reliance on high-temperature processes and fossil fuels. Natural graphite mining, while disruptive to local ecosystems and biodiversity, typically has a lower carbon footprint and generates fewer airborne pollutants. Both methods pose environmental challenges, but synthetic graphite's carbon intensity highlights the need for cleaner production technologies and sustainable energy sources.

Cost Analysis: Manufacturing vs Extraction

Synthetic graphite production typically incurs higher manufacturing costs due to energy-intensive processes like high-temperature graphitization and raw material refinement, whereas natural graphite mining has lower initial extraction expenses but involves significant environmental remediation and beneficiation costs. The capital expenditure for synthetic graphite plants is substantial, driven by complex equipment and controlled conditions, while natural mining demands extensive land acquisition and regulatory compliance, impacting overall profitability. Lifecycle cost analysis reveals synthetic graphite offers more consistent quality and scalability, potentially offsetting higher production costs compared to the variable grade and supply chain uncertainties of natural graphite mining.

Material Purity and Quality Control

Synthetic graphite offers superior material purity compared to natural graphite due to controlled manufacturing processes that minimize impurities such as silica and metallic elements. Quality control in synthetic graphite production involves stringent monitoring of particle size distribution, crystalline structure, and electrical conductivity to ensure consistency and performance in applications like batteries and electrodes. Natural graphite, while cost-effective, often requires extensive purification and grading to meet industrial standards, making synthetic alternatives preferable for high-precision industries.

Industrial Applications and Market Demand

Synthetic graphite offers consistent purity and superior structural uniformity compared to natural graphite, making it ideal for high-performance industrial applications such as battery anodes, refractories, and lubricants. Natural graphite, sourced through mining, remains essential due to its cost-effectiveness and abundance, driving continuous demand in steelmaking, foundries, and expandable graphite production. Market trends indicate growing industrial preference for synthetic graphite in electric vehicle batteries, while natural graphite maintains strong demand in traditional metallurgical sectors.

Sustainability and Resource Availability

Synthetic graphite production consumes significant energy and relies on fossil-based precursors, raising sustainability concerns and carbon footprint issues. Natural graphite mining impacts ecosystems, but advanced extraction techniques and increased recycling efforts help mitigate environmental damage and preserve resource availability. Balancing synthetic and natural graphite sources is critical to ensuring sustainable supply chains amid growing demand in batteries and renewable energy technologies.

Technological Innovations in Synthetic Graphite Production

Technological innovations in synthetic graphite production have enhanced purity levels and structural uniformity, significantly outperforming natural graphite extraction. Advanced processes like chemical vapor deposition and high-temperature graphitization enable precise control over particle size and morphology, resulting in superior electrical conductivity and thermal stability. These improvements drive synthetic graphite's expanding applications in batteries, electronics, and aerospace industries.

Future Trends: Balancing Synthetic and Natural Graphite

Future trends in graphite production emphasize balancing synthetic and natural graphite to meet rising demand in electric vehicle batteries and renewable energy storage. Innovations in synthetic graphite manufacturing aim to reduce environmental impact and production costs, while advancements in natural graphite mining focus on sustainability and resource efficiency. Industry forecasts predict integrated supply chains combining both sources to optimize performance, cost, and ecological footprint.

Synthetic Activity vs Natural Mining Infographic

materialdif.com

materialdif.com