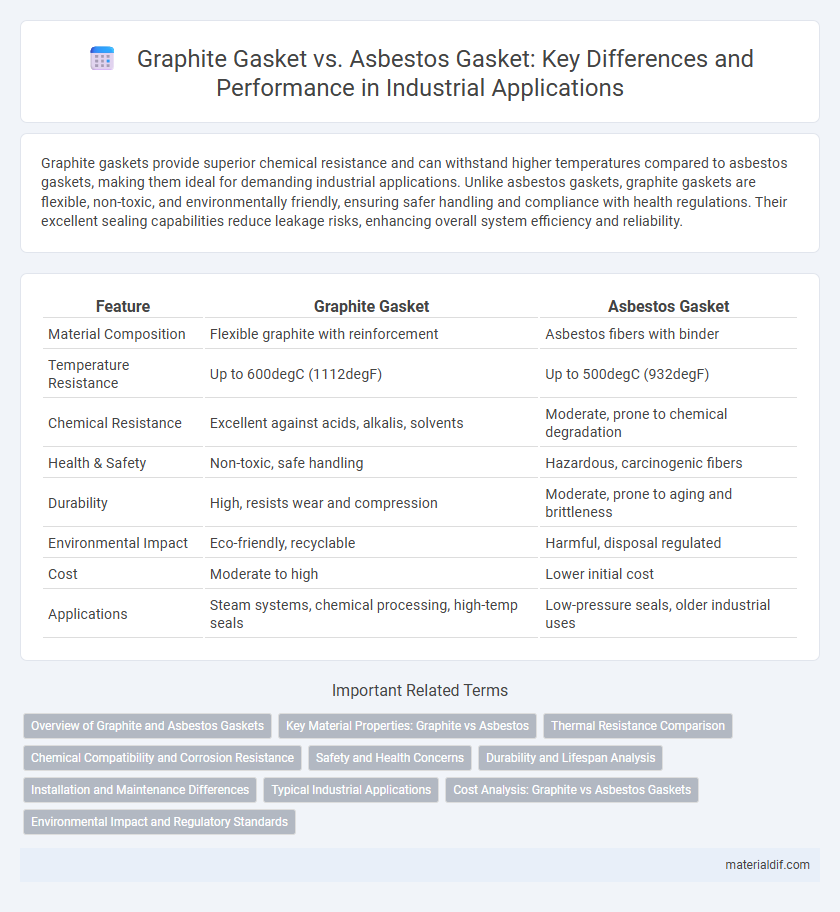

Graphite gaskets provide superior chemical resistance and can withstand higher temperatures compared to asbestos gaskets, making them ideal for demanding industrial applications. Unlike asbestos gaskets, graphite gaskets are flexible, non-toxic, and environmentally friendly, ensuring safer handling and compliance with health regulations. Their excellent sealing capabilities reduce leakage risks, enhancing overall system efficiency and reliability.

Table of Comparison

| Feature | Graphite Gasket | Asbestos Gasket |

|---|---|---|

| Material Composition | Flexible graphite with reinforcement | Asbestos fibers with binder |

| Temperature Resistance | Up to 600degC (1112degF) | Up to 500degC (932degF) |

| Chemical Resistance | Excellent against acids, alkalis, solvents | Moderate, prone to chemical degradation |

| Health & Safety | Non-toxic, safe handling | Hazardous, carcinogenic fibers |

| Durability | High, resists wear and compression | Moderate, prone to aging and brittleness |

| Environmental Impact | Eco-friendly, recyclable | Harmful, disposal regulated |

| Cost | Moderate to high | Lower initial cost |

| Applications | Steam systems, chemical processing, high-temp seals | Low-pressure seals, older industrial uses |

Overview of Graphite and Asbestos Gaskets

Graphite gaskets offer excellent chemical resistance, high-temperature tolerance up to 4500degF, and superior flexibility, making them ideal for sealing applications in extreme environments. Asbestos gaskets, historically known for heat resistance and durability, have been largely phased out due to health risks associated with asbestos fiber inhalation. Modern graphite gaskets provide a safer and more versatile alternative without compromising sealing performance in high-pressure and high-temperature conditions.

Key Material Properties: Graphite vs Asbestos

Graphite gaskets exhibit excellent chemical resistance, high thermal stability up to 650degC, and superior flexibility, making them ideal for harsh industrial environments. Asbestos gaskets, once favored for their heat resistance and durability, pose significant health risks due to fibrous particles and are limited to temperatures around 400degC. The inert nature of graphite ensures minimal gasket degradation and prevents contamination, whereas asbestos fibers can deteriorate, compromising gasket integrity and safety.

Thermal Resistance Comparison

Graphite gaskets exhibit superior thermal resistance compared to asbestos gaskets, withstanding temperatures up to 550degC (1022degF) without degradation, whereas asbestos typically endures only around 300degC (572degF). Graphite's excellent thermal stability and flexibility make it ideal for high-temperature applications in industries like petrochemical and power generation. Its ability to maintain integrity under extreme thermal cycling surpasses asbestos gaskets, ensuring longer service life and enhanced safety.

Chemical Compatibility and Corrosion Resistance

Graphite gaskets offer superior chemical compatibility and corrosion resistance compared to asbestos gaskets, making them ideal for use in aggressive chemical environments and high-temperature applications. Unlike asbestos, graphite withstands a wide range of acids, alkalis, and solvents without degradation, ensuring long-lasting seal integrity. The non-reactive nature of graphite minimizes corrosion risks on flange surfaces, enhancing equipment lifespan and safety.

Safety and Health Concerns

Graphite gaskets offer superior chemical resistance and thermal stability without the toxic risks associated with asbestos gaskets, which have been linked to severe respiratory diseases such as asbestosis and mesothelioma. Graphite's non-fibrous composition drastically reduces health hazards, making it safer for handling and installation in high-temperature industrial applications. Regulatory agencies worldwide have increasingly restricted or banned asbestos use, further emphasizing the importance of switching to graphite gaskets for enhanced safety and compliance.

Durability and Lifespan Analysis

Graphite gaskets exhibit superior durability and a longer lifespan compared to asbestos gaskets due to their exceptional resistance to high temperatures, chemicals, and pressure fluctuations. Graphite's flexibility and self-lubricating properties reduce wear and deformation, enabling extended service intervals in demanding industrial applications. In contrast, asbestos gaskets degrade more rapidly under similar conditions, posing higher replacement and maintenance costs.

Installation and Maintenance Differences

Graphite gaskets offer easier installation due to their flexibility and resilience, allowing them to conform better to flange irregularities without requiring excessive bolt load. Maintenance is simplified because graphite gaskets resist chemicals and high temperatures, resulting in longer service life and fewer replacements compared to asbestos gaskets. Unlike asbestos gaskets, which demand careful handling and disposal due to health hazards, graphite gaskets provide a safer and more environmentally friendly option throughout their lifespan.

Typical Industrial Applications

Graphite gaskets are widely used in high-temperature and corrosive industrial applications such as chemical processing, power generation, and petrochemical plants due to their excellent thermal stability and chemical resistance. In contrast, asbestos gaskets, historically applied in steam systems, boilers, and automotive engines, have been largely replaced because of health hazards despite their initial durability and heat resistance. Modern industries favor graphite gaskets for sealing flange joints in reactors, heat exchangers, and pipelines where safety and environmental compliance are critical.

Cost Analysis: Graphite vs Asbestos Gaskets

Graphite gaskets generally offer a higher upfront cost compared to asbestos gaskets but provide longer service life and superior chemical resistance, reducing maintenance expenses over time. Asbestos gaskets, while cheaper initially, pose significant health and environmental risks leading to regulatory restrictions and potential legal liabilities that can increase long-term costs. Evaluating total cost of ownership reveals graphite gaskets as a cost-effective solution in industrial applications prioritizing safety and durability.

Environmental Impact and Regulatory Standards

Graphite gaskets offer superior environmental benefits compared to asbestos gaskets due to their non-toxic and recyclable nature, reducing hazardous waste and air quality concerns. Regulatory standards such as OSHA and EPA have banned or heavily restricted asbestos use because of carcinogenic risks, leading industries to adopt graphite gaskets for compliance and sustainability. Graphite's thermal stability and chemical resistance also meet stringent environmental regulations while minimizing ecological footprints in industrial applications.

Graphite Gasket vs Asbestos Gasket Infographic

materialdif.com

materialdif.com