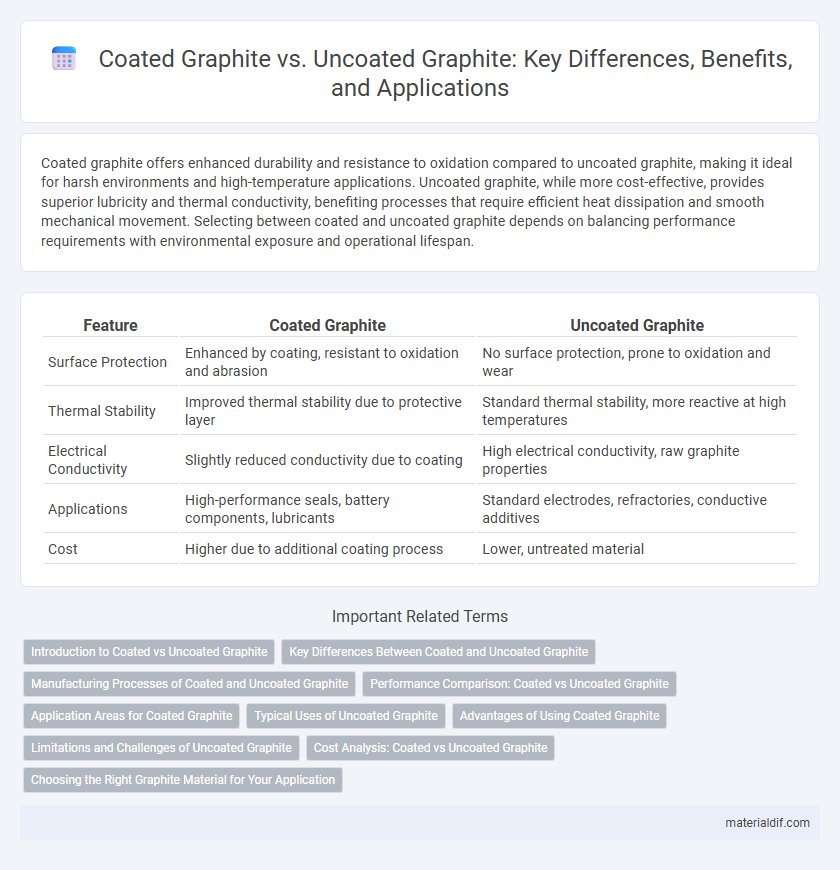

Coated graphite offers enhanced durability and resistance to oxidation compared to uncoated graphite, making it ideal for harsh environments and high-temperature applications. Uncoated graphite, while more cost-effective, provides superior lubricity and thermal conductivity, benefiting processes that require efficient heat dissipation and smooth mechanical movement. Selecting between coated and uncoated graphite depends on balancing performance requirements with environmental exposure and operational lifespan.

Table of Comparison

| Feature | Coated Graphite | Uncoated Graphite |

|---|---|---|

| Surface Protection | Enhanced by coating, resistant to oxidation and abrasion | No surface protection, prone to oxidation and wear |

| Thermal Stability | Improved thermal stability due to protective layer | Standard thermal stability, more reactive at high temperatures |

| Electrical Conductivity | Slightly reduced conductivity due to coating | High electrical conductivity, raw graphite properties |

| Applications | High-performance seals, battery components, lubricants | Standard electrodes, refractories, conductive additives |

| Cost | Higher due to additional coating process | Lower, untreated material |

Introduction to Coated vs Uncoated Graphite

Coated graphite features a protective layer that enhances corrosion resistance and improves sealing properties, making it ideal for high-performance applications. Uncoated graphite offers natural lubrication and thermal stability but lacks the enhanced durability provided by coatings. The choice between coated and uncoated graphite depends on operating conditions such as temperature, chemical exposure, and mechanical stress.

Key Differences Between Coated and Uncoated Graphite

Coated graphite features a protective layer that enhances its oxidation resistance and durability, making it suitable for high-temperature or corrosive environments. Uncoated graphite lacks this protective layer, resulting in higher purity and better electrical conductivity but reduced resistance to wear and chemical attack. The primary difference lies in coated graphite's improved mechanical stability and lifespan, whereas uncoated graphite offers superior thermal conductivity and reactivity for specific industrial applications.

Manufacturing Processes of Coated and Uncoated Graphite

Coated graphite undergoes an additional manufacturing step where it is treated with a thin layer of resin or polymer to enhance its surface properties, such as corrosion resistance and electrical conductivity. Uncoated graphite is produced by compacting or extruding purified natural or synthetic graphite powders without any surface treatment, resulting in a material with inherent porosity and reactivity. The coating process involves curing and heat treatment cycles that improve mechanical strength and durability, making coated graphite suitable for high-performance applications.

Performance Comparison: Coated vs Uncoated Graphite

Coated graphite exhibits enhanced wear resistance and oxidation stability compared to uncoated graphite, making it ideal for high-temperature and high-friction applications. The coating layer reduces surface porosity, improving sealing performance and minimizing gas leakage in mechanical seals and gaskets. Uncoated graphite offers superior thermal conductivity and electrical performance, preferred in applications requiring efficient heat dissipation or electrical conductivity without additional protective layers.

Application Areas for Coated Graphite

Coated graphite is extensively used in high-performance applications such as automotive brake linings, gaskets, and seals, where enhanced wear resistance and improved lubricity are critical. Its protective layer provides superior corrosion resistance and thermal stability, making it ideal for use in extreme temperature environments like aerospace and industrial machinery components. Coated graphite's ability to reduce friction and prevent contamination also makes it valuable in electrical contacts and battery electrodes.

Typical Uses of Uncoated Graphite

Uncoated graphite is commonly used in applications requiring high thermal conductivity and excellent lubrication, such as in brake linings, batteries, and refractory materials. Its natural purity and porous structure make it ideal for electrical contacts, fuel cells, and heat exchangers. Uncoated graphite's intrinsic properties also enhance performance in foundry facings and lubricants without the need for additional coatings.

Advantages of Using Coated Graphite

Coated graphite offers enhanced corrosion resistance and improved durability compared to uncoated graphite, making it ideal for harsh industrial environments. The coating reduces friction and wear, extending the service life of mechanical components such as seals and bearings. Its superior chemical stability also prevents contamination in sensitive applications, ensuring consistent performance and reliability.

Limitations and Challenges of Uncoated Graphite

Uncoated graphite faces challenges such as higher susceptibility to oxidation and wear at elevated temperatures, which limits its durability in demanding industrial applications. Its lack of protective coating leads to increased friction and reduced lubrication efficiency, resulting in faster degradation during mechanical use. These limitations make uncoated graphite less suitable for high-performance environments compared to coated graphite variants.

Cost Analysis: Coated vs Uncoated Graphite

Coated graphite typically incurs higher manufacturing costs due to the additional layering process, enhancing corrosion resistance and durability compared to uncoated graphite. Uncoated graphite offers lower upfront expenses but may result in increased maintenance and replacement costs over time in corrosive environments. Cost analysis reveals coated graphite as a more economical choice for long-term applications, balancing initial investment against service life and performance.

Choosing the Right Graphite Material for Your Application

Coated graphite offers enhanced resistance to oxidation and corrosion, making it ideal for high-temperature and chemically aggressive environments, whereas uncoated graphite provides superior thermal conductivity and electrical performance for applications requiring efficient heat dissipation. Selecting the right graphite material depends on factors such as operating temperature, chemical exposure, and mechanical stress, with coated graphite preferred for durability and uncoated graphite chosen for optimal conductivity. Understanding the specific demands of your application ensures improved performance and longevity by matching graphite's properties to operational requirements.

Coated Graphite vs Uncoated Graphite Infographic

materialdif.com

materialdif.com