Graphite recirculation in the production process involves reusing graphite material to enhance efficiency and reduce waste, while non-recirculation relies on fresh graphite input each cycle, potentially increasing raw material costs. Recirculation methods improve sustainability by minimizing environmental impact and conserving resources without compromising product quality. Non-recirculation processes may offer more consistent purity levels but at the expense of higher operational costs and resource consumption.

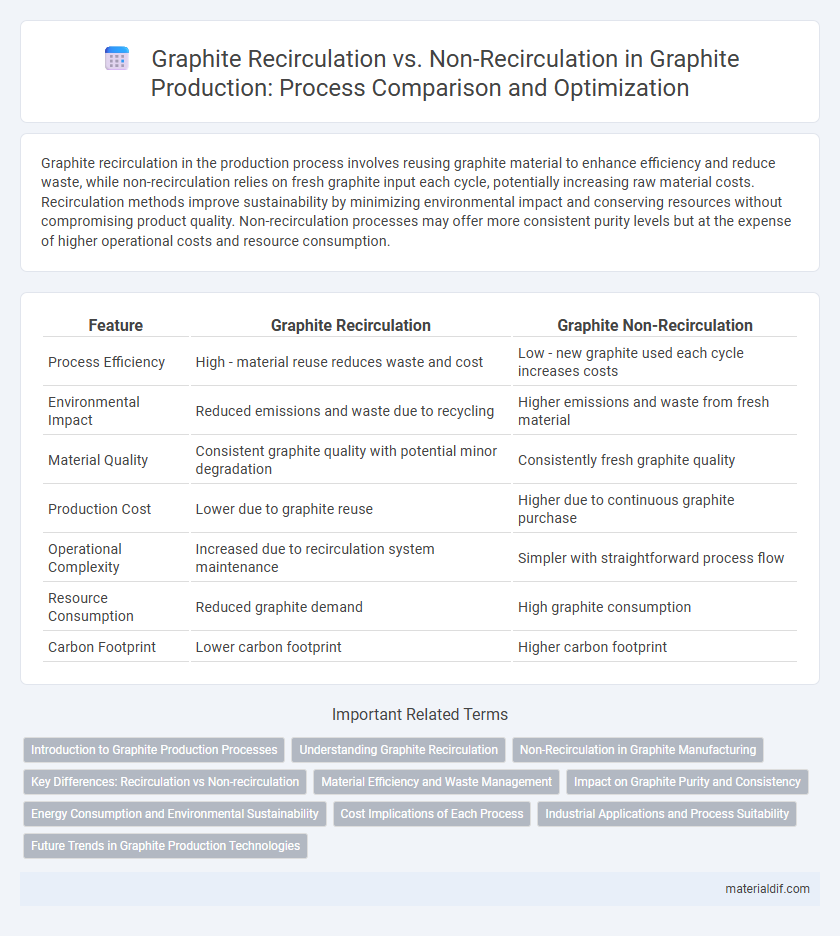

Table of Comparison

| Feature | Graphite Recirculation | Graphite Non-Recirculation |

|---|---|---|

| Process Efficiency | High - material reuse reduces waste and cost | Low - new graphite used each cycle increases costs |

| Environmental Impact | Reduced emissions and waste due to recycling | Higher emissions and waste from fresh material |

| Material Quality | Consistent graphite quality with potential minor degradation | Consistently fresh graphite quality |

| Production Cost | Lower due to graphite reuse | Higher due to continuous graphite purchase |

| Operational Complexity | Increased due to recirculation system maintenance | Simpler with straightforward process flow |

| Resource Consumption | Reduced graphite demand | High graphite consumption |

| Carbon Footprint | Lower carbon footprint | Higher carbon footprint |

Introduction to Graphite Production Processes

Graphite production processes are classified into recirculation and non-recirculation systems, each impacting efficiency and quality differently. Recirculation processes recycle process materials and gases, enhancing resource utilization, reducing waste, and improving product consistency. Non-recirculation methods discharge materials directly, often leading to higher raw material consumption and environmental emissions.

Understanding Graphite Recirculation

Graphite recirculation in production processes involves reusing graphite materials to enhance efficiency, reduce waste, and lower production costs, while non-recirculation methods dispose of used graphite after a single use. Understanding graphite recirculation requires analyzing factors such as material purity, particle size distribution, and the impact on product quality and process stability. Effective recirculation ensures a sustainable supply chain by minimizing raw material consumption and maintaining consistent performance in graphite-dependent manufacturing operations.

Non-Recirculation in Graphite Manufacturing

Non-recirculation in graphite manufacturing involves using fresh process materials without reintroducing waste or off-spec products back into the system, which reduces contamination risks and enhances product purity. This approach often requires higher raw material consumption and increased waste management efforts compared to recirculation processes. Non-recirculation is preferred in high-purity graphite production where consistent quality and material integrity are critical.

Key Differences: Recirculation vs Non-recirculation

Graphite recirculation in production processes involves the reuse of graphite materials to enhance efficiency and reduce waste, whereas non-recirculation systems use fresh graphite for each cycle, leading to higher material consumption. Recirculation methods typically lower overall production costs and environmental impact due to mineral recovery and reduced raw material demand. Non-recirculation, while simpler to implement, often results in increased emissions and raw material depletion, impacting sustainability metrics negatively.

Material Efficiency and Waste Management

Graphite recirculation in production significantly enhances material efficiency by reducing raw graphite consumption and minimizing scrap generation through continuous reuse of graphite particles. Non-recirculation processes typically result in higher waste volumes due to the direct disposal of spent graphite material, leading to increased costs and environmental impact. Implementing graphite recirculation systems supports sustainable waste management by lowering landfill contributions and enabling resource conservation, contributing to eco-friendly production cycles.

Impact on Graphite Purity and Consistency

Graphite recirculation enhances purity by continuously recycling and refining graphite particles, reducing contaminants and improving overall quality. Non-recirculation processes often result in variable graphite consistency due to the lack of repeated purification stages, leading to fluctuations in particle size and impurity levels. Recirculation also stabilizes the production process, enabling more consistent graphite characteristics critical for high-performance applications.

Energy Consumption and Environmental Sustainability

Graphite recirculation in production significantly reduces energy consumption by reusing heat and minimizing raw material processing compared to non-recirculation methods, which rely on continuous input of fresh graphite and higher energy input. This energy efficiency translates into lower greenhouse gas emissions and reduced environmental footprint, enhancing overall sustainability of the manufacturing process. Non-recirculation systems, while simpler, contribute to higher resource depletion and increased waste generation, undermining long-term environmental goals.

Cost Implications of Each Process

Graphite recirculation in production processes reduces raw material waste, leading to lower overall material costs and improved sustainability. Non-recirculation methods often incur higher expenses due to the continuous need for fresh graphite feedstock and increased disposal costs. Energy consumption differs as well, with recirculation systems typically requiring more complex infrastructure but offering long-term cost savings through resource efficiency.

Industrial Applications and Process Suitability

Graphite recirculation in industrial applications enhances material efficiency by reusing graphite particles, reducing waste and lowering raw material costs in processes like battery anode production and refractories manufacturing. Non-recirculation systems, while simpler and less prone to contamination, are better suited for high-purity graphite requirements where consistent material properties are critical, such as in semiconductor or aerospace coatings. Choosing between recirculation and non-recirculation depends on the specific process demands for material quality, environmental impact, and economic considerations in graphite-dependent industries.

Future Trends in Graphite Production Technologies

Graphite recirculation in production processes enhances material efficiency by reprocessing fine particles and reducing waste, leading to lower environmental impact and cost savings. Non-recirculation methods typically involve direct use of mined graphite with minimal reuse, often resulting in higher resource consumption and increased tailings. Future trends emphasize integrating advanced recirculation technologies combined with automation and AI-driven process optimization to achieve higher purity, reduce energy consumption, and promote sustainable graphite production.

Graphite Recirculation vs Non-recirculation (production process) Infographic

materialdif.com

materialdif.com