Graphite blocks offer larger, solid structures ideal for industrial applications requiring high thermal resistance and durability, while graphite rods provide slender, uniform shapes suited for precision tasks like electrodes or conductors. The choice between graphite block and graphite rod depends on the specific application's size, shape, and conductivity requirements. Graphite rods typically allow better control in electrical and chemical environments, whereas blocks excel in mechanical stability and heat distribution.

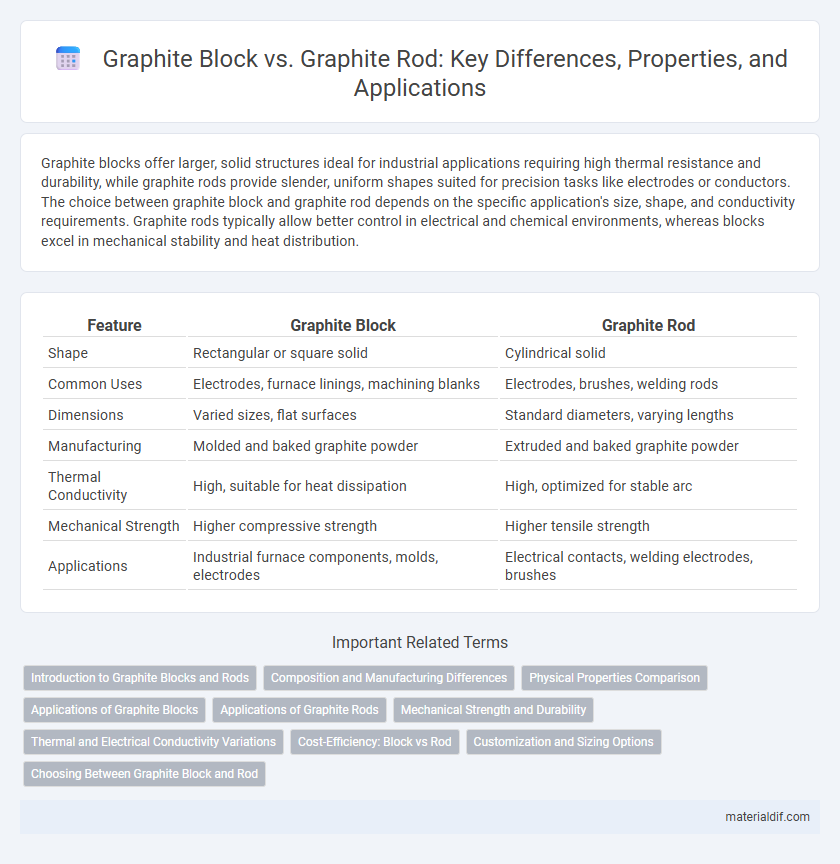

Table of Comparison

| Feature | Graphite Block | Graphite Rod |

|---|---|---|

| Shape | Rectangular or square solid | Cylindrical solid |

| Common Uses | Electrodes, furnace linings, machining blanks | Electrodes, brushes, welding rods |

| Dimensions | Varied sizes, flat surfaces | Standard diameters, varying lengths |

| Manufacturing | Molded and baked graphite powder | Extruded and baked graphite powder |

| Thermal Conductivity | High, suitable for heat dissipation | High, optimized for stable arc |

| Mechanical Strength | Higher compressive strength | Higher tensile strength |

| Applications | Industrial furnace components, molds, electrodes | Electrical contacts, welding electrodes, brushes |

Introduction to Graphite Blocks and Rods

Graphite blocks are large, solid units primarily used in industrial applications for heat resistance and electrical conductivity, while graphite rods are cylindrical forms utilized as electrodes or in precision manufacturing. Both graphite blocks and rods exhibit exceptional thermal stability, high electrical conductivity, and chemical inertness, making them essential in metallurgical, electrical, and chemical industries. The choice between graphite blocks and rods depends on the specific application requirements, such as shape, size, and mechanical strength.

Composition and Manufacturing Differences

Graphite blocks are typically fabricated from synthetic graphite, produced by calcining petroleum coke and coal tar pitch, then baking, graphitizing, and machining into shape, resulting in uniform density and high thermal stability. Graphite rods, in contrast, are often made from natural graphite powders or synthetic graphite, formed by extrusion or isostatic pressing before undergoing similar heat treatments, which can affect their mechanical strength and electrical conductivity. These compositional and manufacturing variations influence the microstructure, porosity, and overall performance of graphite blocks and rods in industrial applications.

Physical Properties Comparison

Graphite blocks typically have higher density and better structural integrity compared to graphite rods, making them ideal for applications requiring durability and stability. Graphite rods are generally more flexible and easier to machine, with lower thermal conductivity and slightly reduced mechanical strength. Both forms exhibit excellent electrical conductivity and thermal resistance, but blocks outperform rods in wear resistance and compressive strength.

Applications of Graphite Blocks

Graphite blocks are widely used in industrial applications requiring high heat resistance and thermal conductivity, such as in metallurgy for furnace linings and heat exchangers. Their dense and durable structure makes them ideal for high-temperature environments where stability and wear resistance are critical. Graphite rods, by contrast, are commonly utilized in applications like electrodes and components in chemical processing due to their machinability and electrical conductivity.

Applications of Graphite Rods

Graphite rods are primarily used as electrodes in electric arc furnaces, batteries, and electrolysis processes due to their excellent electrical conductivity and high thermal resistance. Unlike graphite blocks, which serve structural or insulation purposes in high-temperature environments, graphite rods are favored in applications requiring precision and durability under chemical or mechanical stress. Their versatility in industrial applications includes use in metallurgy, chemical manufacturing, and electrical industries.

Mechanical Strength and Durability

Graphite rods exhibit higher mechanical strength compared to graphite blocks due to their uniform grain structure and reduced porosity, enhancing resistance to deformation under stress. Graphite blocks, however, may offer improved durability in applications involving thermal cycling due to their larger mass and heat dissipation properties. These characteristics influence the selection between graphite rods and blocks based on the specific mechanical and thermal demands of industrial processes.

Thermal and Electrical Conductivity Variations

Graphite blocks exhibit higher thermal conductivity compared to graphite rods due to their dense crystallographic structure and fewer grain boundaries, facilitating superior heat transfer. In contrast, graphite rods, often fabricated with a more porous microstructure, show reduced thermal conductivity but maintain reasonable electrical conductivity suitable for electrode applications. Electrical conductivity varies with orientation and manufacturing process, with graphite blocks generally offering enhanced conductivity along the crystallographic planes, while rods provide consistent conductivity for industrial uses like arc furnace electrodes.

Cost-Efficiency: Block vs Rod

Graphite rods generally offer greater cost-efficiency due to their simpler manufacturing process and lower material usage compared to graphite blocks. While graphite blocks provide higher density and structural integrity, their increased production complexity leads to higher costs, making rods more economical for applications where strength requirements are moderate. Selecting graphite rods can significantly reduce expenses in projects prioritizing budget without compromising essential electrical or thermal conductivity.

Customization and Sizing Options

Graphite blocks offer extensive customization options, including tailored shapes and precise sizing to suit specific industrial applications such as metallurgy and electronics. Graphite rods provide versatile sizing options with customizable diameters and lengths, ideal for manufacturing components requiring high thermal conductivity and electrical resistance. Both graphite blocks and rods can be engineered to meet unique specifications, ensuring optimal performance and integration in specialized environments.

Choosing Between Graphite Block and Rod

Choosing between a graphite block and a graphite rod depends primarily on the application's mechanical and thermal requirements. Graphite blocks offer robust compressive strength and are ideal for machining into complex shapes, making them suitable for molds and heat treatment. Graphite rods provide superior tensile strength and are often used in electrical conductors, electrodes, or components requiring precise cylindrical shapes.

Graphite Block vs Graphite Rod Infographic

materialdif.com

materialdif.com