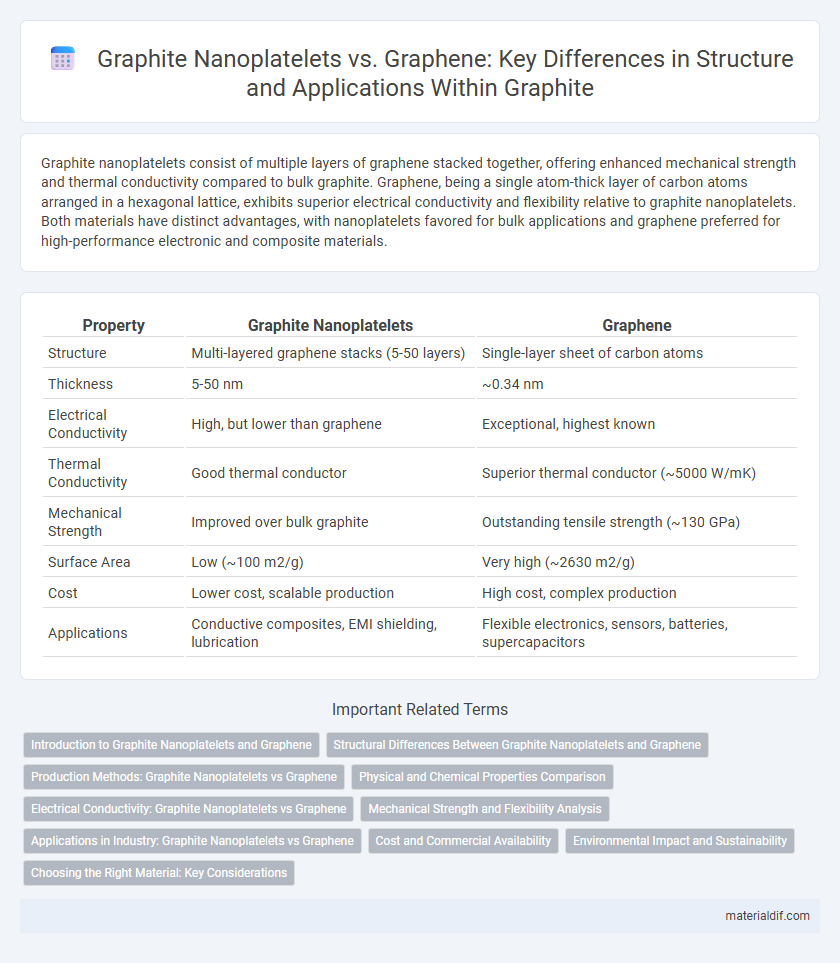

Graphite nanoplatelets consist of multiple layers of graphene stacked together, offering enhanced mechanical strength and thermal conductivity compared to bulk graphite. Graphene, being a single atom-thick layer of carbon atoms arranged in a hexagonal lattice, exhibits superior electrical conductivity and flexibility relative to graphite nanoplatelets. Both materials have distinct advantages, with nanoplatelets favored for bulk applications and graphene preferred for high-performance electronic and composite materials.

Table of Comparison

| Property | Graphite Nanoplatelets | Graphene |

|---|---|---|

| Structure | Multi-layered graphene stacks (5-50 layers) | Single-layer sheet of carbon atoms |

| Thickness | 5-50 nm | ~0.34 nm |

| Electrical Conductivity | High, but lower than graphene | Exceptional, highest known |

| Thermal Conductivity | Good thermal conductor | Superior thermal conductor (~5000 W/mK) |

| Mechanical Strength | Improved over bulk graphite | Outstanding tensile strength (~130 GPa) |

| Surface Area | Low (~100 m2/g) | Very high (~2630 m2/g) |

| Cost | Lower cost, scalable production | High cost, complex production |

| Applications | Conductive composites, EMI shielding, lubrication | Flexible electronics, sensors, batteries, supercapacitors |

Introduction to Graphite Nanoplatelets and Graphene

Graphite nanoplatelets are thin, platelet-shaped particles derived from natural graphite, offering unique mechanical and thermal properties due to their layered structure. Graphene is a single layer of carbon atoms arranged in a two-dimensional hexagonal lattice, known for its exceptional electrical conductivity, strength, and flexibility. While graphene provides superior performance at the atomic level, graphite nanoplatelets serve as a cost-effective alternative for enhancing composite materials and thermal management applications.

Structural Differences Between Graphite Nanoplatelets and Graphene

Graphite nanoplatelets consist of multiple stacked graphene layers, typically ranging from a few to several tens of layers, whereas graphene is a single monolayer of carbon atoms arranged in a hexagonal lattice. The interlayer spacing in graphite nanoplatelets is approximately 0.34 nanometers, resulting in distinct mechanical and electrical properties compared to single-layer graphene. Structural differences influence their surface area, conductivity, and suitability for applications such as composites, sensors, and energy storage devices.

Production Methods: Graphite Nanoplatelets vs Graphene

Graphite nanoplatelets (GNPs) are primarily produced through mechanical exfoliation or chemical oxidation of natural graphite, resulting in few-layer graphene-like structures with larger lateral dimensions but thicker morphology. In contrast, graphene production often employs chemical vapor deposition (CVD), epitaxial growth, or more refined exfoliation techniques to achieve monolayer or few-layer films with higher electrical conductivity and mechanical strength. The scalability and cost-effectiveness of GNP production methods make them favorable for bulk industrial applications, whereas graphene's complex synthesis routes target high-performance electronic and composite materials.

Physical and Chemical Properties Comparison

Graphite nanoplatelets consist of multiple stacked graphene layers, exhibiting high mechanical strength, excellent thermal conductivity, and chemical stability similar to graphene but with reduced surface area and electrical conductivity. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, offering exceptional tensile strength, superior electrical conductivity, and higher surface reactivity due to its monolayer structure. Both materials demonstrate significant potential for enhancing composite materials, but graphene's atomic-scale thickness affords it unique electronic and chemical properties not found in graphite nanoplatelets.

Electrical Conductivity: Graphite Nanoplatelets vs Graphene

Graphene exhibits superior electrical conductivity compared to graphite nanoplatelets due to its single-layer, two-dimensional atomic structure that allows for efficient electron mobility. Graphite nanoplatelets consist of multiple graphene layers stacked together, which results in increased electron scattering and reduced conductivity. This structural difference is pivotal in applications requiring high electrical conductivity, where graphene significantly outperforms graphite nanoplatelets.

Mechanical Strength and Flexibility Analysis

Graphite nanoplatelets exhibit superior mechanical strength compared to graphene due to their multilayered structure, providing enhanced load-bearing capacity and resistance to fracture. In flexibility analysis, graphene outperforms graphite nanoplatelets because of its single-layer atomic arrangement, allowing exceptional bendability and elastic deformation. The balance between strength and flexibility in these carbon nanomaterials depends on their structural morphology, with nanoplatelets ideal for reinforcement and graphene suitable for flexible electronics.

Applications in Industry: Graphite Nanoplatelets vs Graphene

Graphite nanoplatelets offer enhanced thermal conductivity and mechanical reinforcement for composites used in automotive and aerospace industries, making them ideal for lightweight structural components. Graphene provides superior electrical conductivity and flexibility, driving innovations in flexible electronics, sensors, and energy storage devices. Both materials enable advancements in industrial applications, with graphite nanoplatelets favored for bulk thermal management and graphene for high-performance nanoelectronics.

Cost and Commercial Availability

Graphite nanoplatelets are more cost-effective and commercially available in larger quantities compared to graphene, making them preferable for bulk industrial applications. Graphene production remains expensive and limited by complex manufacturing processes, restricting its widespread commercial use. This cost and availability disparity drives the preference for graphite nanoplatelets in cost-sensitive markets requiring scalable material supply.

Environmental Impact and Sustainability

Graphite nanoplatelets offer a lower environmental impact compared to graphene due to their simpler production processes that consume less energy and generate fewer emissions. Their scalability and lower manufacturing costs contribute to more sustainable industrial applications while maintaining effective mechanical and thermal properties. Despite graphene's superior strength and conductivity, graphite nanoplatelets present a more eco-friendly alternative in sustainability-focused material development.

Choosing the Right Material: Key Considerations

Graphene offers exceptional electrical conductivity and mechanical strength due to its single-layer atomic structure, making it ideal for high-performance applications. Graphite nanoplatelets provide a cost-effective alternative with good thermal conductivity and ease of dispersion, useful in composites and coatings. Selecting the right material depends on balancing performance requirements, scalability, and budget constraints specific to industries such as electronics, energy storage, and thermal management.

Graphite Nanoplatelets vs Graphene Infographic

materialdif.com

materialdif.com