Graphene production involves extracting single or few layers of carbon atoms from graphite, requiring advanced methods like chemical vapor deposition or exfoliation, which are more complex and cost-intensive compared to graphite production. Graphite production primarily focuses on mining and processing naturally occurring carbon-rich materials, making it more abundant and less expensive. The distinct manufacturing processes result in graphene exhibiting superior electrical, thermal, and mechanical properties, while graphite remains widely used in traditional applications such as batteries and lubricants.

Table of Comparison

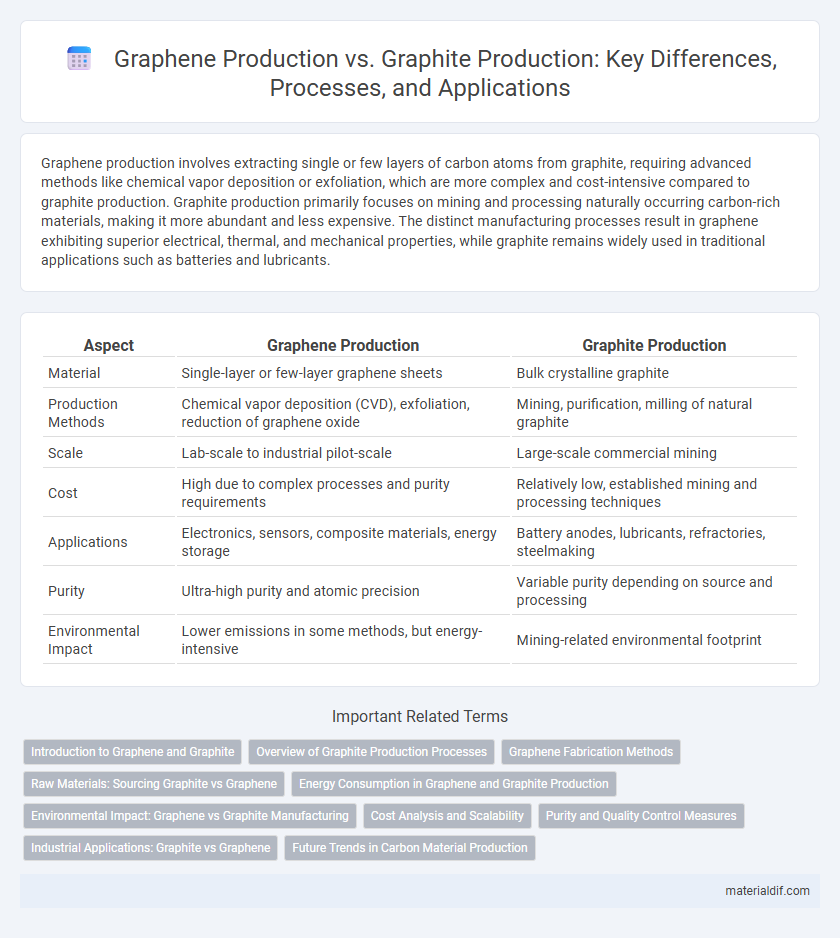

| Aspect | Graphene Production | Graphite Production |

|---|---|---|

| Material | Single-layer or few-layer graphene sheets | Bulk crystalline graphite |

| Production Methods | Chemical vapor deposition (CVD), exfoliation, reduction of graphene oxide | Mining, purification, milling of natural graphite |

| Scale | Lab-scale to industrial pilot-scale | Large-scale commercial mining |

| Cost | High due to complex processes and purity requirements | Relatively low, established mining and processing techniques |

| Applications | Electronics, sensors, composite materials, energy storage | Battery anodes, lubricants, refractories, steelmaking |

| Purity | Ultra-high purity and atomic precision | Variable purity depending on source and processing |

| Environmental Impact | Lower emissions in some methods, but energy-intensive | Mining-related environmental footprint |

Introduction to Graphene and Graphite

Graphite, a naturally occurring form of carbon, serves as the primary raw material for graphene production, which involves exfoliating graphite layers into single-atom-thick sheets. While global graphite production exceeds millions of tons annually for industrial applications, graphene production remains in the nascent stage, measured in grams to kilograms due to complex fabrication processes. Graphene's exceptional electrical, thermal, and mechanical properties distinguish it from bulk graphite, driving rapidly growing research and high-value applications despite its current production scale.

Overview of Graphite Production Processes

Graphite production primarily involves extracting natural graphite through mining or producing synthetic graphite via high-temperature processing of carbon-rich materials. Key methods include flaky and lump graphite mining, followed by purifying and milling to achieve desired grades for industrial use. Synthetic graphite production utilizes coke and pitch through graphitization at temperatures exceeding 2500degC, offering consistent properties for applications like electrodes and battery anodes.

Graphene Fabrication Methods

Graphene fabrication methods include chemical vapor deposition (CVD), mechanical exfoliation, and liquid-phase exfoliation, enabling high-quality graphene sheets from graphite sources. Unlike bulk graphite production, which primarily involves mining and processing natural graphite, graphene production requires precise techniques to isolate single or few-layer graphene with superior electrical and mechanical properties. Advances in scalable fabrication methods, such as CVD on copper substrates, have significantly enhanced graphene yield and consistency compared to conventional graphite extraction.

Raw Materials: Sourcing Graphite vs Graphene

Graphite production relies heavily on natural mining of crystalline carbon deposits, primarily sourced from countries like China, Brazil, and Canada, making raw material availability region-specific and geologically dependent. Graphene production, by contrast, often originates from processed graphite through methods such as chemical vapor deposition or exfoliation, requiring high-purity graphite flakes as feedstock, thus making the quality of raw graphite essential for efficient graphene yield. The efficient sourcing of raw graphite directly influences the scalability and cost-effectiveness of graphene production, highlighting the importance of high-grade graphite reserves in the supply chain.

Energy Consumption in Graphene and Graphite Production

Graphene production typically requires significantly higher energy consumption compared to traditional graphite production due to processes such as chemical vapor deposition and exfoliation techniques. Graphite mining and processing involve comparatively lower energy usage, primarily focusing on mining, purification, and milling. The energy-intensive nature of graphene synthesis impacts its cost and environmental footprint, influencing industrial scalability and application development.

Environmental Impact: Graphene vs Graphite Manufacturing

Graphene production generally exhibits a lower environmental impact compared to traditional graphite manufacturing due to its reduced energy consumption and fewer chemical byproducts. The synthesis of graphene often utilizes advanced methods like chemical vapor deposition and exfoliation, which minimize waste and greenhouse gas emissions relative to graphite mining and processing. As a result, graphene manufacturing supports sustainable material innovation with a smaller ecological footprint than conventional graphite extraction.

Cost Analysis and Scalability

Graphite production currently benefits from established mining infrastructure, resulting in lower per-unit costs but limited scalability due to resource depletion and environmental concerns. Graphene production, while promising superior material properties, faces high manufacturing costs and scalability challenges linked to complex synthesis methods such as chemical vapor deposition and exfoliation. Advances in scalable, cost-effective graphene production techniques are critical to compete with graphite's economic and industrial footprint.

Purity and Quality Control Measures

Graphene production involves advanced techniques such as chemical vapor deposition and exfoliation to achieve high purity levels exceeding 99.99%, crucial for its exceptional electrical and mechanical properties. In contrast, graphite production focuses on large-scale mining and milling, where purity ranges from 90% to 99%, necessitating rigorous quality control measures like flotation and chemical treatments to remove impurities. Quality control in graphene emphasizes atomic-scale inspection tools such as Raman spectroscopy and electron microscopy, whereas graphite quality control relies more on elemental analysis and structural consistency assessments.

Industrial Applications: Graphite vs Graphene

Graphite production remains significantly higher than graphene production, primarily due to graphite's widespread industrial applications such as electrodes in electric arc furnaces, lubricants, and batteries. Graphene, though produced at a smaller scale, is rapidly gaining traction in advanced sectors like flexible electronics, high-strength composites, and energy storage due to its superior electrical conductivity and mechanical strength. The scalable manufacturing of graphene is still a challenge, limiting its immediate industrial adoption compared to the mature graphite market.

Future Trends in Carbon Material Production

Graphene production is poised to revolutionize carbon material manufacturing with its exceptional electrical conductivity and mechanical strength, surpassing traditional graphite applications. Emerging methods like chemical vapor deposition and liquid phase exfoliation offer scalable, cost-effective solutions, accelerating commercial viability. Future trends indicate a shift towards hybrid carbon materials, integrating graphene's properties with graphite to enhance energy storage and electronic devices.

Graphene Production vs Graphite Production Infographic

materialdif.com

materialdif.com