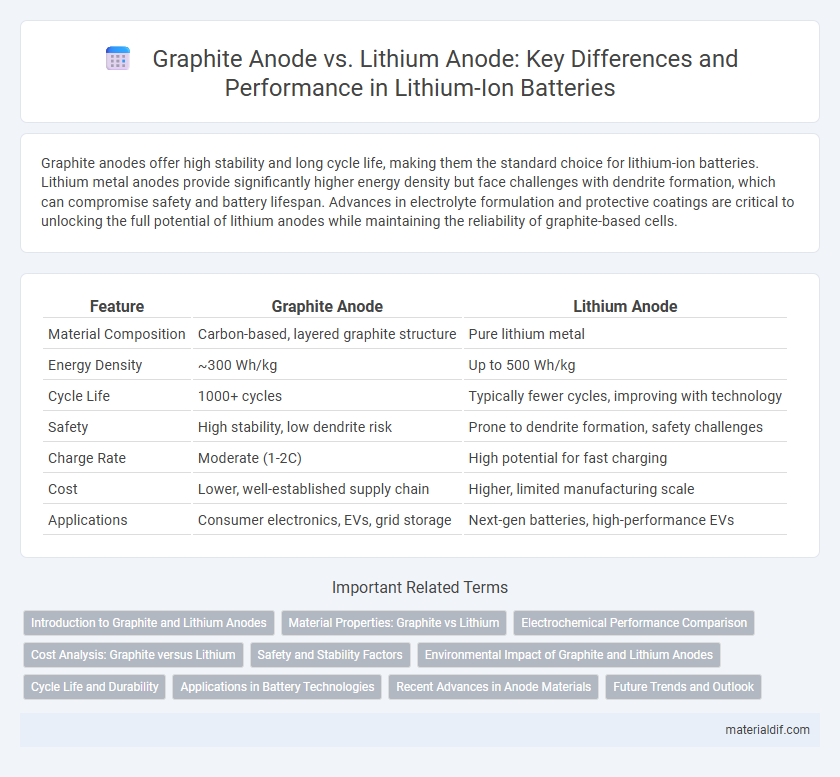

Graphite anodes offer high stability and long cycle life, making them the standard choice for lithium-ion batteries. Lithium metal anodes provide significantly higher energy density but face challenges with dendrite formation, which can compromise safety and battery lifespan. Advances in electrolyte formulation and protective coatings are critical to unlocking the full potential of lithium anodes while maintaining the reliability of graphite-based cells.

Table of Comparison

| Feature | Graphite Anode | Lithium Anode |

|---|---|---|

| Material Composition | Carbon-based, layered graphite structure | Pure lithium metal |

| Energy Density | ~300 Wh/kg | Up to 500 Wh/kg |

| Cycle Life | 1000+ cycles | Typically fewer cycles, improving with technology |

| Safety | High stability, low dendrite risk | Prone to dendrite formation, safety challenges |

| Charge Rate | Moderate (1-2C) | High potential for fast charging |

| Cost | Lower, well-established supply chain | Higher, limited manufacturing scale |

| Applications | Consumer electronics, EVs, grid storage | Next-gen batteries, high-performance EVs |

Introduction to Graphite and Lithium Anodes

Graphite anodes are widely used in lithium-ion batteries due to their high electrical conductivity and layered structure, which allows efficient lithium-ion intercalation and deintercalation. Lithium metal anodes offer higher theoretical capacity and energy density but face challenges like dendrite formation and safety concerns that limit commercial adoption. Understanding the electrochemical properties and stability differences between graphite and lithium anodes is critical for advancing next-generation battery technologies.

Material Properties: Graphite vs Lithium

Graphite anodes exhibit high structural stability, excellent electrical conductivity, and a layered carbon structure that facilitates lithium ion intercalation, making them the standard choice in lithium-ion batteries. Lithium metal anodes offer significantly higher theoretical capacity and lower electrochemical potential, but suffer from dendrite formation and poor cycle stability due to their soft, reactive nature. The contrasting material properties--graphite's mechanical robustness versus lithium's high energy density--drive ongoing research to optimize battery performance and safety.

Electrochemical Performance Comparison

Graphite anodes exhibit a high cyclic stability and a moderate specific capacity of about 370 mAh/g, making them the industry standard for lithium-ion batteries. Lithium metal anodes offer a significantly higher theoretical capacity of 3860 mAh/g and lower electrochemical potential, enabling enhanced energy density and faster charging rates. However, lithium anodes face challenges like dendrite formation and limited cycle life, which impact their practical electrochemical performance compared to graphite.

Cost Analysis: Graphite versus Lithium

Graphite anodes exhibit significantly lower production costs compared to lithium metal anodes due to abundant natural reserves and established manufacturing processes. Lithium anodes require advanced handling and safety measures, increasing overall cell production expenses, impacting product scalability. Cost-efficient graphite enables competitive pricing in lithium-ion batteries, while lithium anodes demand breakthroughs in material stabilization to reduce cost barriers.

Safety and Stability Factors

Graphite anodes exhibit superior safety and stability compared to lithium metal anodes due to their stable solid electrolyte interphase (SEI) formation, which minimizes dendrite growth and reduces the risk of short circuits. Lithium metal anodes, while offering higher theoretical capacity, suffer from significant safety challenges including lithium dendrite formation, leading to potential thermal runaway and battery failure. Advanced graphite anode designs enhance cycle life and thermal stability, making them the preferred choice for commercial lithium-ion batteries where safety and long-term reliability are critical.

Environmental Impact of Graphite and Lithium Anodes

Graphite anodes exhibit a lower environmental impact compared to lithium anodes due to their abundant natural availability and less intensive mining processes, resulting in reduced carbon emissions and ecological disruption. Lithium extraction involves high water consumption and habitat degradation, especially in arid regions like the Lithium Triangle of South America, contributing to significant environmental degradation. Recycling of graphite anodes is more feasible and energy-efficient, enhancing their sustainability profile against lithium anodes whose recycling infrastructure remains underdeveloped.

Cycle Life and Durability

Graphite anodes exhibit superior cycle life and durability compared to lithium metal anodes due to their stable intercalation mechanism, which minimizes volume expansion and enhances structural integrity over multiple charge-discharge cycles. Lithium metal anodes face challenges with dendrite formation and significant volume changes, leading to reduced cycle stability and increased safety risks. Advances in graphite anode formulations and surface coatings further improve their long-term performance in lithium-ion batteries.

Applications in Battery Technologies

Graphite anodes dominate commercial lithium-ion batteries due to their stable cycling performance and high Coulombic efficiency, making them ideal for consumer electronics and electric vehicles. Lithium metal anodes offer significantly higher specific capacity and energy density, which is critical for next-generation batteries targeting extended driving ranges and longer device usage times. Challenges in lithium anode applications include dendrite formation and safety concerns, prompting research into advanced solid electrolytes and protective coatings to enhance battery longevity and performance.

Recent Advances in Anode Materials

Recent advances in anode materials highlight the shift from traditional graphite anodes to lithium metal anodes, driven by lithium's higher theoretical capacity of approximately 3860 mAh/g compared to graphite's 372 mAh/g. Researchers have developed novel nanostructured lithium anodes and protective solid electrolyte interphases (SEI) to mitigate dendrite formation and improve cycling stability. These innovations promise enhanced energy density and longer battery life for next-generation lithium-ion and lithium-metal batteries.

Future Trends and Outlook

Graphite anodes currently dominate lithium-ion battery technology due to their proven stability and cost-effectiveness, while lithium metal anodes promise significantly higher energy density and faster charging capabilities. Future trends indicate increasing research investments in lithium metal anode development to overcome challenges such as dendrite formation and cycle life limitations. The outlook for battery technology involves hybrid approaches and solid-state electrolytes that could enable safe, high-performance lithium anodes, potentially revolutionizing electric vehicles and grid storage markets.

Graphite Anode vs Lithium Anode Infographic

materialdif.com

materialdif.com