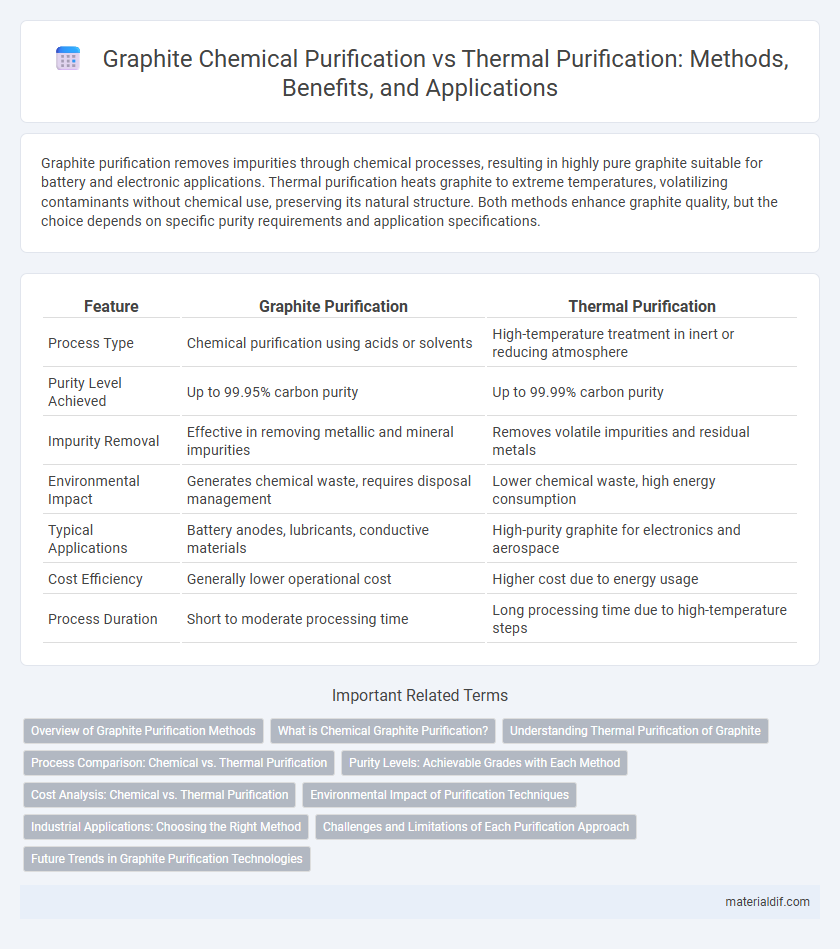

Graphite purification removes impurities through chemical processes, resulting in highly pure graphite suitable for battery and electronic applications. Thermal purification heats graphite to extreme temperatures, volatilizing contaminants without chemical use, preserving its natural structure. Both methods enhance graphite quality, but the choice depends on specific purity requirements and application specifications.

Table of Comparison

| Feature | Graphite Purification | Thermal Purification |

|---|---|---|

| Process Type | Chemical purification using acids or solvents | High-temperature treatment in inert or reducing atmosphere |

| Purity Level Achieved | Up to 99.95% carbon purity | Up to 99.99% carbon purity |

| Impurity Removal | Effective in removing metallic and mineral impurities | Removes volatile impurities and residual metals |

| Environmental Impact | Generates chemical waste, requires disposal management | Lower chemical waste, high energy consumption |

| Typical Applications | Battery anodes, lubricants, conductive materials | High-purity graphite for electronics and aerospace |

| Cost Efficiency | Generally lower operational cost | Higher cost due to energy usage |

| Process Duration | Short to moderate processing time | Long processing time due to high-temperature steps |

Overview of Graphite Purification Methods

Graphite purification methods primarily include chemical purification and thermal purification, each targeting impurities to enhance graphite quality for industrial applications. Chemical purification typically involves acid treatments to remove metallic contaminants, while thermal purification uses high temperatures above 2500degC in inert atmospheres to eliminate residual ash and non-carbon elements. The choice between these methods depends on desired purity levels, with thermal purification achieving ultra-high purity suitable for advanced battery anodes and nuclear-grade graphite.

What is Chemical Graphite Purification?

Chemical graphite purification involves using chemical agents to remove impurities such as iron, silica, and alumina from raw graphite ore, enhancing its purity and performance. This process typically employs acids, alkaline solutions, or oxidizing agents to dissolve and separate contaminants without altering the graphite's crystalline structure. Compared to thermal purification, chemical methods offer precise control over impurity removal, resulting in high-purity graphite suitable for applications in batteries, electronics, and nuclear reactors.

Understanding Thermal Purification of Graphite

Thermal purification of graphite involves heating graphite to extremely high temperatures, typically above 2500degC, in an inert or reducing atmosphere to remove impurities. This process effectively eliminates metallic and non-metallic contaminants, resulting in high-purity graphite suitable for advanced applications such as lithium-ion batteries and nuclear reactors. Compared to chemical purification, thermal purification offers superior impurity removal without introducing additional chemicals, ensuring enhanced electrical conductivity and structural integrity.

Process Comparison: Chemical vs. Thermal Purification

Graphite purification involves chemical purification, which uses acidic or alkaline solutions to dissolve impurities, resulting in high-purity graphite suitable for battery anodes and electronic applications. Thermal purification employs high temperatures, often exceeding 2500degC, to vaporize non-carbon impurities, offering a cleaner process but requiring significant energy input and specialized equipment. Chemical purification allows precise control over impurity removal at lower temperatures, while thermal purification ensures higher purity levels by eliminating a broader range of contaminants through oxidation and sublimation.

Purity Levels: Achievable Grades with Each Method

Graphite purification methods vary significantly in purity levels, with chemical graphite purification achieving between 99.5% to 99.9% carbon content by removing impurities via acid leaching and other chemical treatments. Thermal purification, involving high-temperature treatment above 2500degC in inert or vacuum conditions, can produce ultrahigh purity graphite exceeding 99.99% carbon by eliminating metallic and non-carbon contaminants. The choice between chemical and thermal purification depends on the target application's required purity grade, with thermal methods preferred for electronic and nuclear industry standards demanding the highest purity.

Cost Analysis: Chemical vs. Thermal Purification

Chemical graphite purification typically offers lower operational costs compared to thermal purification due to reduced energy consumption and simpler processing requirements. Thermal purification demands high temperatures exceeding 2000degC, leading to significant energy expenses and specialized equipment investments. Cost analysis favors chemical methods for scalability and economic efficiency, especially in large-scale graphite production applications.

Environmental Impact of Purification Techniques

Graphite purification techniques significantly affect environmental sustainability with chemical graphite purification often involving hazardous acids and generating toxic waste, posing higher environmental risks. Thermal purification methods, such as high-temperature treatment under inert atmospheres, reduce chemical use and minimize harmful effluents but consume substantial energy, raising concerns about carbon emissions. Balancing the environmental impact necessitates optimizing energy efficiency in thermal processes while developing greener chemical alternatives.

Industrial Applications: Choosing the Right Method

Graphite purification methods significantly impact industrial applications, where high purity levels are essential for optimal performance in lithium-ion batteries, semiconductors, and refractory materials. Chemical graphite purification typically achieves purities above 99.95%, ideal for electronic components requiring minimal impurities, while thermal purification uses high-temperature treatments to remove volatiles and metallic contaminants, suitable for bulk industrial uses like steelmaking and crucibles. Selecting between chemical and thermal purification depends on the required purity level, cost considerations, and the specific industrial application's tolerance to residual impurities.

Challenges and Limitations of Each Purification Approach

Graphite purification faces challenges such as the removal of metal impurities and maintaining structural integrity, with chemical purification sometimes causing surface damage and incomplete impurity removal. Thermal purification requires extremely high temperatures, leading to energy-intensive processes and potential graphitization defects that affect material quality. Both methods struggle to balance cost, efficiency, and the purity levels needed for advanced applications like lithium-ion batteries and nuclear reactors.

Future Trends in Graphite Purification Technologies

Emerging trends in graphite purification emphasize advanced chemical methods such as high-efficiency flotation and hydrochloric acid leaching to achieve ultra-high purity levels above 99.9%. Thermal purification remains crucial for producing battery-grade graphite, yet innovations aim to reduce energy consumption through microwave and plasma-based techniques. Future developments increasingly integrate AI-driven process optimization and sustainable practices to enhance yield and minimize environmental impact.

Graphite Purification vs Thermal Purification Infographic

materialdif.com

materialdif.com