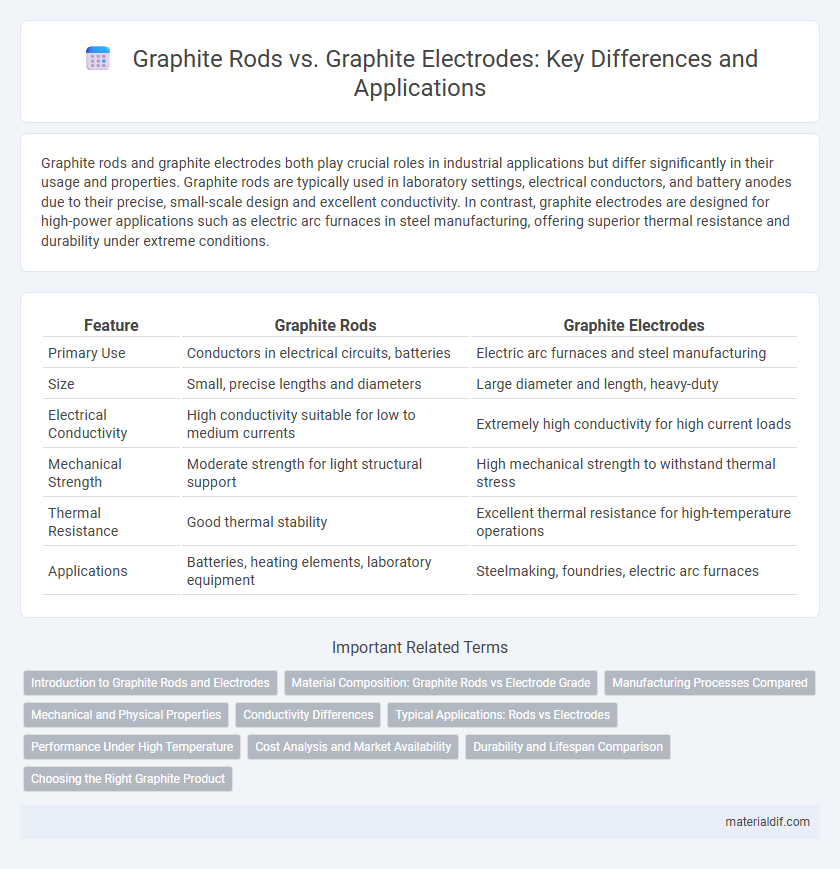

Graphite rods and graphite electrodes both play crucial roles in industrial applications but differ significantly in their usage and properties. Graphite rods are typically used in laboratory settings, electrical conductors, and battery anodes due to their precise, small-scale design and excellent conductivity. In contrast, graphite electrodes are designed for high-power applications such as electric arc furnaces in steel manufacturing, offering superior thermal resistance and durability under extreme conditions.

Table of Comparison

| Feature | Graphite Rods | Graphite Electrodes |

|---|---|---|

| Primary Use | Conductors in electrical circuits, batteries | Electric arc furnaces and steel manufacturing |

| Size | Small, precise lengths and diameters | Large diameter and length, heavy-duty |

| Electrical Conductivity | High conductivity suitable for low to medium currents | Extremely high conductivity for high current loads |

| Mechanical Strength | Moderate strength for light structural support | High mechanical strength to withstand thermal stress |

| Thermal Resistance | Good thermal stability | Excellent thermal resistance for high-temperature operations |

| Applications | Batteries, heating elements, laboratory equipment | Steelmaking, foundries, electric arc furnaces |

Introduction to Graphite Rods and Electrodes

Graphite rods are solid carbon components primarily used as electrodes in various electrochemical applications due to their excellent electrical conductivity and chemical stability. Graphite electrodes, larger and often hollow, are specially designed for high-current applications such as electric arc furnaces in steel manufacturing, offering superior heat resistance and mechanical strength. Both graphite rods and electrodes leverage graphite's unique properties for efficient electrical conduction and durability in industrial processes.

Material Composition: Graphite Rods vs Electrode Grade

Graphite rods are typically made from a lower grade of graphite, designed for applications like electrical discharge machining and general conductivity, where purity and density are less critical. In contrast, graphite electrodes are manufactured using electrode-grade graphite characterized by high purity, high density, and excellent electrical conductivity, essential for electric arc furnace operations in steelmaking. The difference in material composition affects their mechanical strength, thermal stability, and electrical performance, with electrode-grade graphite exhibiting superior qualities for industrial heavy-duty use.

Manufacturing Processes Compared

Graphite rods are typically manufactured through the extrusion of graphite powder mixed with a binder, followed by drying and baking to achieve desired shape and density. Graphite electrodes undergo a more complex process involving mixing petroleum coke and coal tar pitch, forming via molding or extrusion, baking at high temperatures, and subsequent graphitization at around 3000degC to enhance electrical conductivity. The higher-temperature graphitization and shaping techniques in electrodes result in superior structural integrity and conductivity compared to the simpler fabrication of graphite rods.

Mechanical and Physical Properties

Graphite rods exhibit high mechanical strength and excellent thermal conductivity, making them ideal for precision applications where stability and heat dissipation are critical. In contrast, graphite electrodes possess superior electrical conductivity and thermal shock resistance, essential for sustaining high-current environments in electric arc furnaces. Both materials benefit from low thermal expansion and high chemical resistance, but rods emphasize rigidity, while electrodes prioritize current-carrying capacity and durability under intense operational conditions.

Conductivity Differences

Graphite electrodes exhibit higher electrical conductivity compared to graphite rods due to their denser microstructure and enhanced purity tailored for electric arc furnace operations. The optimized porosity and grain alignment in graphite electrodes facilitate efficient current transfer, making them superior in high-temperature industrial applications. Graphite rods, often used in laboratory or low-current settings, have lower conductivity resulting from their less dense composition and manufacturing processes.

Typical Applications: Rods vs Electrodes

Graphite rods find typical applications in electrical discharge machining (EDM), laboratory electrodes for electrochemical experiments, and as components in high-temperature furnaces due to their thermal conductivity and resistance to thermal shock. Graphite electrodes are predominantly used in electric arc furnaces for steel production, where their high electrical conductivity supports the intense current required for melting scrap metal. While rods are favored for precision and smaller-scale applications, electrodes serve large industrial processes demanding robust performance under heavy electrical loads.

Performance Under High Temperature

Graphite rods exhibit excellent thermal conductivity and stability, making them ideal for applications requiring consistent performance under high temperatures. Graphite electrodes, designed for electric arc furnaces, feature enhanced resistance to thermal shock and mechanical wear, ensuring durability during intense heating cycles. While both maintain structural integrity at elevated temperatures, electrodes provide superior electrical conductivity critical for industrial metallurgical processes.

Cost Analysis and Market Availability

Graphite rods generally offer a lower cost alternative compared to graphite electrodes, primarily due to their simpler manufacturing process and lower grade application requirements. Graphite electrodes, essential in electric arc furnace steelmaking, demand higher purity and durability, resulting in higher prices but greater market demand and limited availability from specialized suppliers. Market availability of graphite rods is broader, serving diverse industries such as batteries and chemical processing, while electrodes are confined to metallurgical and high-temperature applications, impacting their supply chain dynamics and pricing structures.

Durability and Lifespan Comparison

Graphite rods exhibit moderate durability and a typical lifespan suited for applications like electrical brushes and batteries, while graphite electrodes are engineered for extreme conditions in electric arc furnaces, offering significantly higher wear resistance and longevity. The dense microstructure and high purity of graphite electrodes enable them to withstand intense thermal and mechanical stresses, extending their service life compared to standard graphite rods. This durability difference highlights graphite electrodes' suitability for industrial metallurgical processes requiring sustained high performance.

Choosing the Right Graphite Product

Graphite rods offer precise electrical conductivity and thermal resistance ideal for applications like arc lamps and electrolysis, while graphite electrodes are specifically engineered for high current conductivity in electric arc furnaces for steelmaking. Selecting the right graphite product depends on factors such as required current capacity, mechanical strength, and operational temperature conditions. Understanding the specific industrial use and performance demands ensures optimal efficiency and longevity of the graphite material.

Graphite Rods vs Graphite Electrodes Infographic

materialdif.com

materialdif.com