Pyrolytic graphite exhibits a highly ordered, layered structure with superior thermal conductivity and anisotropic electrical properties compared to graphitized carbon, making it ideal for specialized electronic and heat management applications. Graphitized carbon, produced through the high-temperature treatment of carbonaceous materials, offers a more random crystalline structure and versatile mechanical strength suited for industrial uses like electrodes and reinforcement materials. Understanding the distinctions in crystallinity and thermal behavior between these materials is crucial for selecting the appropriate form of graphite-based pet for specific technological and manufacturing needs.

Table of Comparison

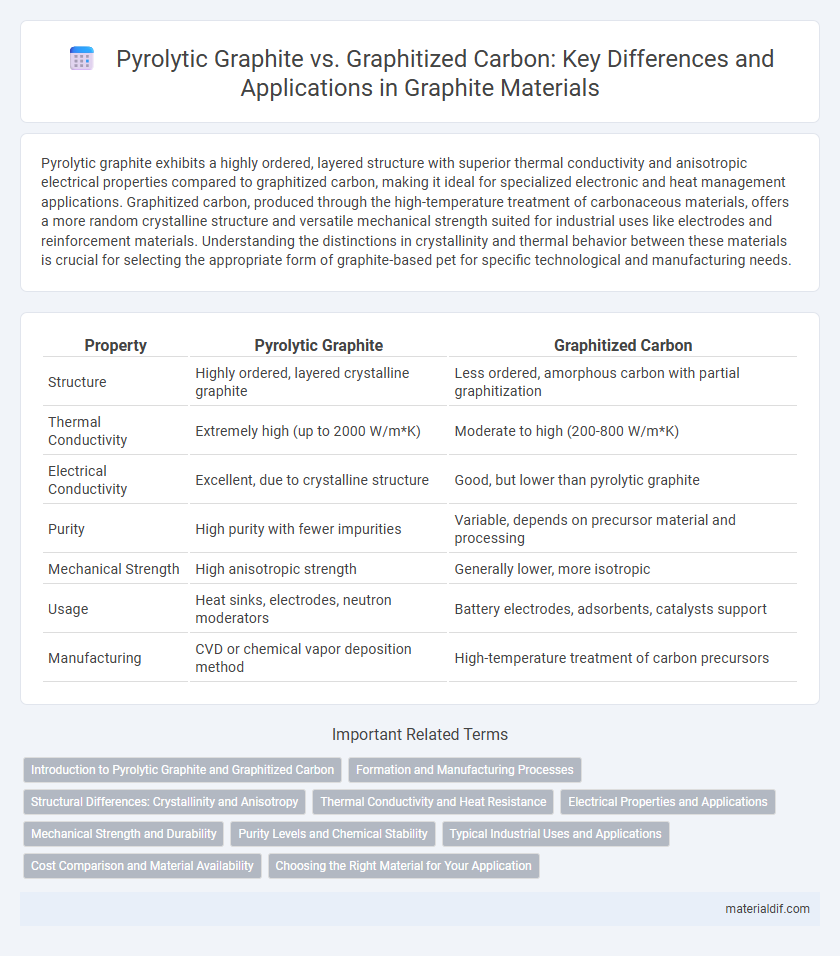

| Property | Pyrolytic Graphite | Graphitized Carbon |

|---|---|---|

| Structure | Highly ordered, layered crystalline graphite | Less ordered, amorphous carbon with partial graphitization |

| Thermal Conductivity | Extremely high (up to 2000 W/m*K) | Moderate to high (200-800 W/m*K) |

| Electrical Conductivity | Excellent, due to crystalline structure | Good, but lower than pyrolytic graphite |

| Purity | High purity with fewer impurities | Variable, depends on precursor material and processing |

| Mechanical Strength | High anisotropic strength | Generally lower, more isotropic |

| Usage | Heat sinks, electrodes, neutron moderators | Battery electrodes, adsorbents, catalysts support |

| Manufacturing | CVD or chemical vapor deposition method | High-temperature treatment of carbon precursors |

Introduction to Pyrolytic Graphite and Graphitized Carbon

Pyrolytic graphite is a highly ordered form of carbon produced by chemical vapor deposition, exhibiting exceptional anisotropic thermal and electrical conductivity along its basal planes. Graphitized carbon refers to carbon materials that have undergone high-temperature graphitization, resulting in increased crystallinity and improved electrical conductivity compared to amorphous carbon. Both materials are integral in applications requiring superior thermal management and electrical performance, with pyrolytic graphite offering superior directional properties and graphitized carbon providing enhanced bulk conductivity.

Formation and Manufacturing Processes

Pyrolytic graphite forms through high-temperature chemical vapor deposition, where hydrocarbons decompose on a heated substrate, resulting in anisotropic, highly ordered layers with superior thermal conductivity. In contrast, graphitized carbon is produced by subjecting carbonaceous precursors to graphitization at temperatures above 2500degC, transforming amorphous carbon into more crystalline, graphitic structures through rearrangement of atomic layers. The distinct manufacturing workflows significantly influence their microstructures, with pyrolytic graphite exhibiting layered orientation controlled by deposition conditions, while graphitized carbon reflects the purity and precursor nature of the starting material.

Structural Differences: Crystallinity and Anisotropy

Pyrolytic graphite exhibits high crystallinity with well-aligned graphene layers, resulting in pronounced anisotropy in its thermal and electrical conductivities. In contrast, graphitized carbon typically contains less ordered graphitic domains with more defects and random orientation, leading to reduced anisotropic properties. The structural differences significantly influence their performance in applications requiring directional conductivity or thermal management.

Thermal Conductivity and Heat Resistance

Pyrolytic graphite exhibits exceptional thermal conductivity, with values reaching up to 1500 W/m*K along its basal plane, outperforming most graphitized carbon materials, which typically have thermal conductivities around 100-400 W/m*K. Its anisotropic heat conduction allows efficient dissipation of heat, making it ideal for high-performance thermal management applications. Pyrolytic graphite also demonstrates superior heat resistance, maintaining structural integrity at temperatures above 3000degC in inert atmospheres, whereas graphitized carbon materials generally degrade at lower temperatures under similar conditions.

Electrical Properties and Applications

Pyrolytic graphite exhibits exceptional anisotropic electrical conductivity, with in-plane conductivity values reaching up to 10^5 S/m, making it ideal for electronic heat spreaders and electromagnetic shielding. In contrast, graphitized carbon, with more isotropic but generally lower conductivity around 10^3 to 10^4 S/m, is widely used in battery electrodes and fuel cells due to its stable electrochemical performance. The distinct electrical properties stem from pyrolytic graphite's highly ordered graphene layers, whereas graphitized carbon features a less uniform structure impacting its electrical behavior and application scope.

Mechanical Strength and Durability

Pyrolytic graphite exhibits superior mechanical strength and durability compared to graphitized carbon due to its highly ordered layered structure and strong covalent bonding within the graphene planes. The anisotropic nature of pyrolytic graphite enhances its resistance to mechanical stress and thermal shock, making it ideal for high-performance applications. In contrast, graphitized carbon typically has lower mechanical integrity and is more prone to fracture under stress because of its less uniform microstructure.

Purity Levels and Chemical Stability

Pyrolytic graphite exhibits higher purity levels with fewer impurities compared to graphitized carbon, resulting in superior chemical stability and resistance to oxidation. Its layered crystalline structure enhances durability under harsh chemical environments, making it ideal for high-temperature applications. In contrast, graphitized carbon often contains more structural defects and impurities, reducing its chemical stability and limiting its use in corrosive conditions.

Typical Industrial Uses and Applications

Pyrolytic graphite is commonly used in applications requiring exceptional thermal conductivity and electromagnetic shielding, such as heat spreaders in electronics and neutron moderators in nuclear reactors. Graphitized carbon, known for its mechanical strength and chemical stability, finds typical industrial use in high-temperature furnace components, electrodes for electric arc furnaces, and refractory materials. Both materials serve critical roles in industries like aerospace, electronics, and metallurgy due to their unique structural and thermal properties.

Cost Comparison and Material Availability

Pyrolytic graphite typically incurs higher production costs due to its complex manufacturing process involving chemical vapor deposition, resulting in limited availability and niche applications. In contrast, graphitized carbon is generally more cost-effective, benefiting from conventional graphitization techniques applied to carbon precursors, leading to wider material availability and broader industrial use. The cost-efficiency and scalability of graphitized carbon make it the preferred choice for bulk applications, whereas pyrolytic graphite suits specialized fields demanding superior anisotropic thermal and electrical properties.

Choosing the Right Material for Your Application

Pyrolytic graphite offers exceptional thermal conductivity and anisotropic properties, making it ideal for high-performance thermal management and electronic applications. Graphitized carbon, characterized by its isotropic structure and ease of machining, is better suited for chemical processing and mechanical components requiring moderate conductivity and durability. Selecting the right material depends on application-specific needs such as thermal performance, mechanical strength, and chemical resistance.

Pyrolytic Graphite vs Graphitized Carbon Infographic

materialdif.com

materialdif.com