Friction graphite is primarily used to enhance lubrication and reduce wear in mechanical applications, providing a smooth, durable surface. Conductive graphite, on the other hand, excels in electrical conductivity and is commonly applied in electronic components and conductive coatings. Understanding the distinct physical and chemical properties of friction and conductive graphite is essential for selecting the right material based on performance requirements.

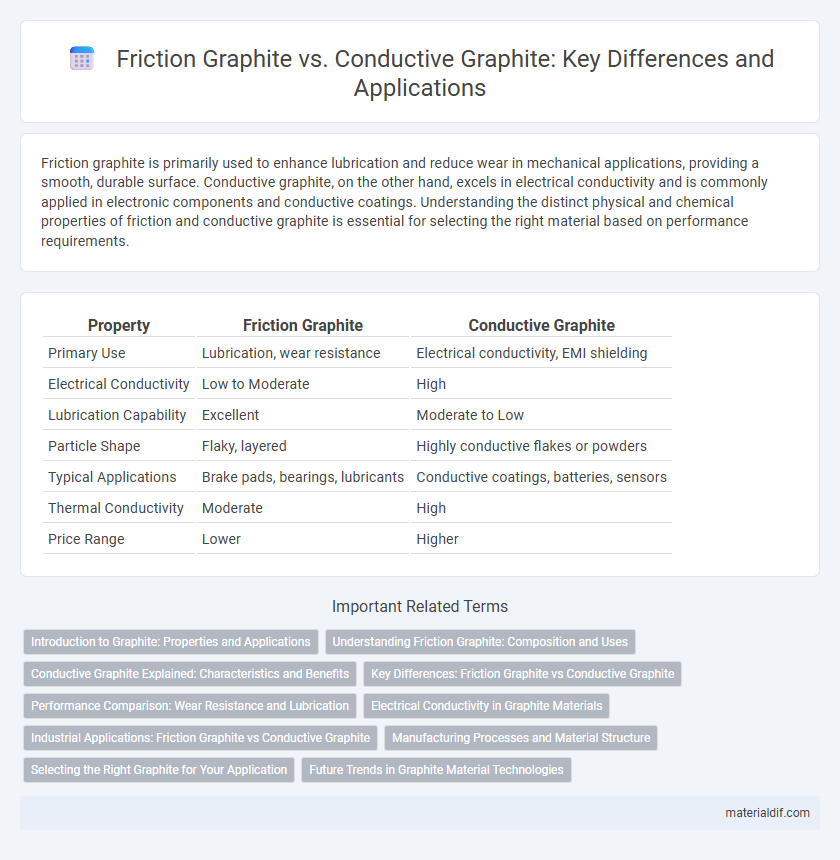

Table of Comparison

| Property | Friction Graphite | Conductive Graphite |

|---|---|---|

| Primary Use | Lubrication, wear resistance | Electrical conductivity, EMI shielding |

| Electrical Conductivity | Low to Moderate | High |

| Lubrication Capability | Excellent | Moderate to Low |

| Particle Shape | Flaky, layered | Highly conductive flakes or powders |

| Typical Applications | Brake pads, bearings, lubricants | Conductive coatings, batteries, sensors |

| Thermal Conductivity | Moderate | High |

| Price Range | Lower | Higher |

Introduction to Graphite: Properties and Applications

Graphite exhibits distinct properties that categorize it into friction graphite and conductive graphite, each tailored for specific industrial applications. Friction graphite is optimized for lubrication and wear resistance in mechanical systems, while conductive graphite excels in electrical conductivity for electrodes and battery components. Understanding these variations enhances the effective utilization of graphite in manufacturing, electronics, and energy storage solutions.

Understanding Friction Graphite: Composition and Uses

Friction graphite consists primarily of natural graphite combined with binders and additives to enhance wear resistance and thermal stability, making it ideal for brake linings and clutch materials. Its layered carbon structure provides excellent lubricity and heat dissipation, crucial for reducing friction and wear in mechanical systems. Unlike conductive graphite, which focuses on electrical conductivity, friction graphite is optimized for mechanical performance in high-stress environments.

Conductive Graphite Explained: Characteristics and Benefits

Conductive graphite exhibits exceptional electrical conductivity due to its unique layered structure, making it ideal for applications in batteries, sensors, and electronic devices. Its high purity and consistent particle size enhance charge transfer efficiency, leading to improved performance in conductive coatings and composite materials. Additionally, conductive graphite offers excellent thermal stability and corrosion resistance, extending the lifespan and reliability of electronic components.

Key Differences: Friction Graphite vs Conductive Graphite

Friction graphite is primarily used in brake pads and clutch materials due to its excellent wear resistance and high lubricity, which reduce heat and friction during operation. Conductive graphite, on the other hand, is optimized for electrical conductivity and is commonly employed in batteries, electrodes, and conductive coatings to facilitate efficient electron transfer. The key differences lie in their physical properties and applications: friction graphite emphasizes mechanical durability and thermal stability, while conductive graphite prioritizes electrical performance and connectivity.

Performance Comparison: Wear Resistance and Lubrication

Friction graphite exhibits superior wear resistance due to its layered crystal structure, which reduces material degradation during mechanical contact, making it ideal for applications requiring consistent lubrication and durability. Conductive graphite, while offering excellent electrical conductivity, generally has lower wear resistance and is more prone to abrasion under frictional stress. Performance comparisons reveal that friction graphite maintains lubrication effectiveness longer, reducing tool wear and energy consumption in industrial machinery.

Electrical Conductivity in Graphite Materials

Friction graphite typically exhibits lower electrical conductivity due to its structure optimized for wear resistance and lubrication properties rather than electron flow. Conductive graphite is engineered with higher purity and crystalline order, enhancing free electron movement and resulting in superior electrical conductivity. The electrical conductivity of conductive graphite can reach up to 10,000 S/m, whereas friction graphite's conductivity commonly remains under 1,000 S/m.

Industrial Applications: Friction Graphite vs Conductive Graphite

Friction graphite is extensively used in industrial brake linings, clutch materials, and lubricants due to its excellent wear resistance and high-temperature stability, improving performance and durability in automotive and heavy machinery applications. Conductive graphite is essential for electrical applications, including battery electrodes, conductive coatings, and electronic components, where its high electrical conductivity and chemical inertness enhance efficiency and reliability. Industrial sectors rely on friction graphite for mechanical durability and conductive graphite for superior electrical performance, tailoring material choice to application-specific requirements.

Manufacturing Processes and Material Structure

Friction graphite is produced through high-temperature baking and graphitization, resulting in a porous, irregular microstructure optimized for lubrication and wear resistance. Conductive graphite undergoes precise extrusion or molding followed by controlled graphitization, creating a dense, uniform crystalline structure that enhances electrical conductivity. Differences in manufacturing processes directly influence material properties, with friction graphite prioritizing mechanical stability and conductive graphite emphasizing electron mobility.

Selecting the Right Graphite for Your Application

Selecting the right graphite depends on the application's specific requirements for friction and conductivity. Friction graphite provides excellent lubrication and wear resistance, ideal for mechanical components and high-friction environments. Conductive graphite offers superior electrical conductivity, making it suitable for electrodes, batteries, and electronic devices where efficient current flow is essential.

Future Trends in Graphite Material Technologies

Friction graphite improves wear resistance and lubrication properties, making it essential in automotive brake pads and industrial machinery, while conductive graphite prioritizes electrical conductivity for applications in batteries, fuel cells, and electronic components. Emerging trends highlight nanostructured graphite and graphene-enhanced composites, which offer superior performance in both friction and conductivity by optimizing surface area and electron mobility. Future developments focus on sustainable production methods and integration with advanced materials like silicon anodes, driving innovation in energy storage and friction-reducing technologies.

Friction Graphite vs Conductive Graphite Infographic

materialdif.com

materialdif.com