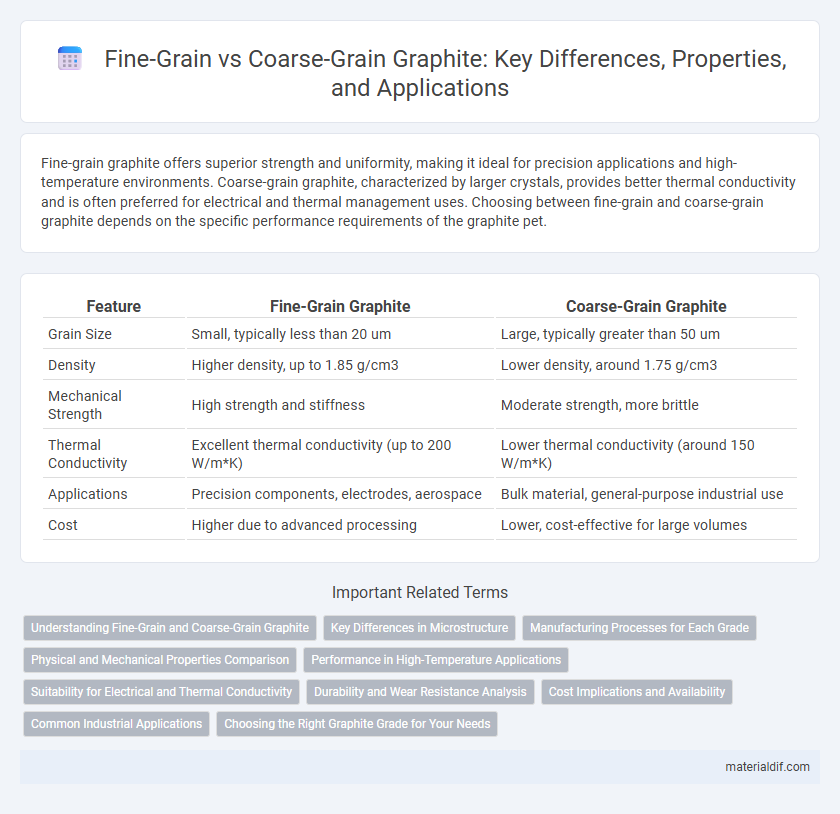

Fine-grain graphite offers superior strength and uniformity, making it ideal for precision applications and high-temperature environments. Coarse-grain graphite, characterized by larger crystals, provides better thermal conductivity and is often preferred for electrical and thermal management uses. Choosing between fine-grain and coarse-grain graphite depends on the specific performance requirements of the graphite pet.

Table of Comparison

| Feature | Fine-Grain Graphite | Coarse-Grain Graphite |

|---|---|---|

| Grain Size | Small, typically less than 20 um | Large, typically greater than 50 um |

| Density | Higher density, up to 1.85 g/cm3 | Lower density, around 1.75 g/cm3 |

| Mechanical Strength | High strength and stiffness | Moderate strength, more brittle |

| Thermal Conductivity | Excellent thermal conductivity (up to 200 W/m*K) | Lower thermal conductivity (around 150 W/m*K) |

| Applications | Precision components, electrodes, aerospace | Bulk material, general-purpose industrial use |

| Cost | Higher due to advanced processing | Lower, cost-effective for large volumes |

Understanding Fine-Grain and Coarse-Grain Graphite

Fine-grain graphite consists of small, uniformly distributed graphite particles, which enhance strength and improve wear resistance in high-stress applications. Coarse-grain graphite features larger particles, providing superior thermal conductivity and electrical performance, making it ideal for heat management and electrical contacts. Understanding the balance between fine-grain and coarse-grain graphite properties is crucial for optimizing material selection based on mechanical, thermal, and electrical requirements.

Key Differences in Microstructure

Fine-grain graphite exhibits a microstructure characterized by smaller, more uniformly distributed graphite particles, resulting in higher mechanical strength and improved wear resistance. Coarse-grain graphite features larger, irregularly shaped graphite flakes or particles that contribute to enhanced thermal conductivity but lower structural integrity. The distinct microstructural variations directly influence the material's performance in applications requiring specific mechanical and thermal properties.

Manufacturing Processes for Each Grade

Fine-grain graphite manufacturing involves precise control of raw materials, pulverizing coke and pitch into very small particles, followed by isostatic pressing to achieve uniform density and fine microstructure. Coarse-grain graphite production typically uses larger particle sizes and extrusion or vibration molding methods, resulting in a more heterogeneous microstructure with higher permeability. The key distinction lies in the particle size distribution and molding technique, which directly influence the mechanical properties and applications of each graphite grade.

Physical and Mechanical Properties Comparison

Fine-grain graphite exhibits higher strength and hardness due to its smaller and more uniform grain size, resulting in improved wear resistance and mechanical stability under stress compared to coarse-grain graphite. Coarse-grain graphite, characterized by larger grain structures, shows lower tensile strength and increased porosity, which reduces its density and mechanical integrity but allows better thermal shock resistance. The fine-grain variety typically demonstrates greater elastic modulus and fracture toughness, making it more suitable for precision applications requiring high durability and dimensional stability.

Performance in High-Temperature Applications

Fine-grain graphite exhibits superior performance in high-temperature applications due to its higher density and lower porosity, which enhance thermal conductivity and mechanical strength. Its fine microstructure resists thermal shock and oxidation better than coarse-grain graphite, ensuring longevity in extreme environments such as furnaces and reactors. Coarse-grain graphite, while having higher thermal shock resistance in some contexts, generally suffers from lower mechanical stability and increased oxidation rates at elevated temperatures.

Suitability for Electrical and Thermal Conductivity

Fine-grain graphite exhibits superior electrical and thermal conductivity due to its closely packed crystal structure, making it ideal for applications requiring efficient heat dissipation and electrical current flow, such as in electrodes and heat exchangers. Coarse-grain graphite, characterized by larger crystal sizes and lower density, offers reduced conductivity but enhanced mechanical strength and thermal shock resistance, which suits it for applications where structural integrity under stress is prioritized over maximum conductivity. Selecting fine-grain or coarse-grain graphite depends on balancing conductivity demands with mechanical and thermal stability requirements in specific industrial uses.

Durability and Wear Resistance Analysis

Fine-grain graphite exhibits superior durability and wear resistance due to its uniform microstructure and reduced porosity, which enhances mechanical strength and reduces fracture risk. In contrast, coarse-grain graphite tends to have larger grain boundaries that act as stress concentrators, leading to lower wear resistance and higher susceptibility to cracking under mechanical stress. The improved homogeneity of fine-grain graphite makes it ideal for applications requiring high wear performance and long service life in abrasive environments.

Cost Implications and Availability

Fine-grain graphite typically commands higher costs due to its refined structure demanding more intensive processing, whereas coarse-grain graphite is generally more affordable and abundant, making it suitable for large-scale industrial applications. Availability of fine-grain graphite is limited by the scarcity of high-purity raw materials and specialized manufacturing techniques, while coarse-grain graphite remains widely accessible from multiple global mining sources. Cost implications favor coarse-grain graphite for projects with budget constraints, whereas fine-grain graphite's premium pricing reflects its superior performance in precision technologies.

Common Industrial Applications

Fine-grain graphite, characterized by a particle size below 20 microns, is widely used in precision instruments, battery anodes, and electrical contacts due to its excellent electrical conductivity and high mechanical strength. Coarse-grain graphite, with larger particle sizes above 50 microns, finds applications in high-temperature industrial processes such as crucibles, foundry molds, and refractory linings where superior thermal shock resistance is required. Both types are essential in steel manufacturing, but fine-grain graphite is preferred for components demanding precision and longevity, while coarse-grain graphite suits large-scale metallurgical applications.

Choosing the Right Graphite Grade for Your Needs

Fine-grain graphite offers superior machinability, higher strength, and better thermal conductivity, making it ideal for precision components and applications requiring intricate detailing. Coarse-grain graphite provides greater porosity and lower density, which suits applications needing high thermal shock resistance and wear resistance. Selecting the right graphite grade depends on specific requirements such as mechanical properties, thermal performance, and manufacturing processes.

Fine-Grain Graphite vs Coarse-Grain Graphite Infographic

materialdif.com

materialdif.com