Isotropic graphite exhibits uniform properties in all directions due to its randomly oriented grains, making it ideal for applications requiring consistent mechanical strength and thermal conductivity. Anisotropic graphite, with its grains aligned in specific directions, offers enhanced performance where directional properties like increased electrical conductivity or thermal expansion are beneficial. Selecting between isotropic and anisotropic graphite depends on the application's demand for uniformity versus directional strength and conductivity.

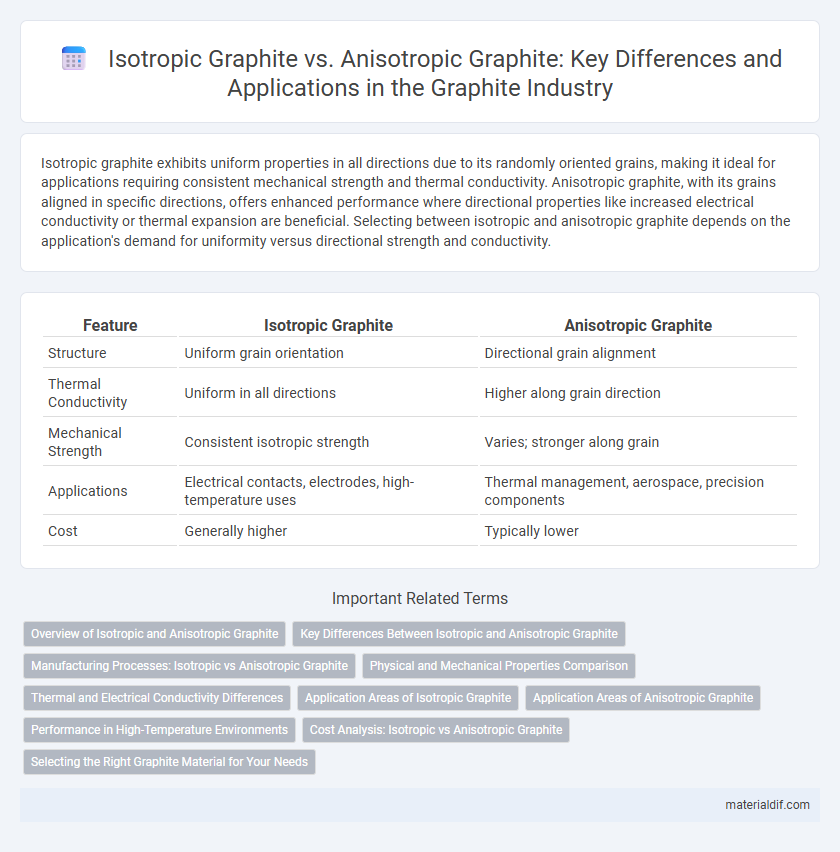

Table of Comparison

| Feature | Isotropic Graphite | Anisotropic Graphite |

|---|---|---|

| Structure | Uniform grain orientation | Directional grain alignment |

| Thermal Conductivity | Uniform in all directions | Higher along grain direction |

| Mechanical Strength | Consistent isotropic strength | Varies; stronger along grain |

| Applications | Electrical contacts, electrodes, high-temperature uses | Thermal management, aerospace, precision components |

| Cost | Generally higher | Typically lower |

Overview of Isotropic and Anisotropic Graphite

Isotropic graphite possesses uniform physical properties in all directions due to its microstructure, making it ideal for applications requiring consistent strength and thermal conductivity. Anisotropic graphite exhibits directional differences in mechanical and thermal properties, resulting from its aligned grain structure, which enhances performance in specialized industrial processes. Understanding the distinction between isotropic and anisotropic graphite is critical for selecting the appropriate material in high-temperature electrodes, aerospace components, and nuclear reactors.

Key Differences Between Isotropic and Anisotropic Graphite

Isotropic graphite exhibits uniform properties in all directions due to its homogeneous microstructure, making it ideal for applications requiring consistent strength and thermal conductivity. In contrast, anisotropic graphite features directional properties, with variations in thermal expansion and conductivity aligned along its grain structure, which benefits uses needing specific directional performance. The key differences lie in their manufacturing processes, with isotropic graphite produced through fine coke blending for uniformity, while anisotropic graphite results from natural or extruded materials that create layered anisotropy.

Manufacturing Processes: Isotropic vs Anisotropic Graphite

Isotropic graphite is manufactured through a process involving fine coke and pitch, which are baked and then graphitized under high temperatures to produce uniform properties in all directions. Anisotropic graphite, in contrast, is typically produced by machining or extrusion methods that align the grain structure, resulting in directional properties that vary depending on the axis. The choice between isotropic and anisotropic graphite manufacturing processes directly impacts mechanical strength, thermal conductivity, and electrical resistivity tailored for specific industrial applications.

Physical and Mechanical Properties Comparison

Isotropic graphite exhibits uniform physical and mechanical properties in all directions, featuring consistent thermal conductivity and strength, making it suitable for applications requiring predictable performance under stress. In contrast, anisotropic graphite displays direction-dependent properties, with higher thermal conductivity and mechanical strength along the grain direction but weaker properties perpendicular to it, affecting its reliability in multi-directional stress environments. The choice between isotropic and anisotropic graphite depends on the required balance of strength, thermal management, and dimensional stability for specific industrial uses.

Thermal and Electrical Conductivity Differences

Isotropic graphite exhibits uniform thermal and electrical conductivity in all directions due to its randomly oriented graphite grains, making it ideal for applications requiring consistent performance. Anisotropic graphite has significantly higher conductivity along the grain planes compared to the perpendicular direction, resulting from its aligned crystalline structure. This directional difference in anisotropic graphite leads to enhanced electrical and thermal conduction parallel to the layers but reduced performance across them.

Application Areas of Isotropic Graphite

Isotropic graphite, known for its uniform properties in all directions, is widely used in applications requiring consistent thermal expansion and high structural integrity, such as in nuclear reactors, aerospace components, and precision instruments. Its excellent machinability and resistance to thermal shock make it ideal for manufacturing electrodes in electric arc furnaces and components in semiconductor production. These characteristics differentiate isotropic graphite from anisotropic graphite, which is better suited for applications needing directional conductivity and strength.

Application Areas of Anisotropic Graphite

Anisotropic graphite exhibits directional properties that make it ideal for applications requiring controlled electrical and thermal conductivity, such as in electrodes for electric arc furnaces, battery anodes, and heat sinks in electronic devices. Its anisotropy allows for superior mechanical strength and thermal expansion in specific directions, enhancing performance in aerospace components and nuclear reactors. These characteristics position anisotropic graphite as a critical material for industries demanding precision and efficiency in high-temperature and high-stress environments.

Performance in High-Temperature Environments

Isotropic graphite exhibits uniform thermal conductivity and expansion in all directions, making it highly stable under rapid temperature fluctuations in high-temperature environments. Anisotropic graphite demonstrates directional thermal conductivity, which can lead to uneven thermal stresses but offers superior performance in applications requiring specific heat dissipation paths. The choice between isotropic and anisotropic graphite significantly impacts durability and efficiency in furnaces, reactors, and aerospace components operating above 2500degC.

Cost Analysis: Isotropic vs Anisotropic Graphite

Isotropic graphite typically incurs higher production costs due to its uniform grain structure achieved through specialized manufacturing processes like extrusion or molding. Anisotropic graphite, often produced by standard carbonization methods, tends to be less expensive owing to its directional grain orientation and simpler fabrication techniques. When evaluating cost-effectiveness, isotropic graphite offers superior mechanical properties and thermal stability that may justify the premium in high-performance applications.

Selecting the Right Graphite Material for Your Needs

Isotropic graphite offers uniform properties in all directions, making it ideal for applications requiring consistent thermal and electrical conductivity. Anisotropic graphite exhibits directional properties, which can be leveraged for specialized uses like electrodes or nuclear reactors where specific thermal expansion or strength characteristics are crucial. Evaluating application requirements such as thermal stability, mechanical strength, and electrical conductivity helps determine whether isotropic or anisotropic graphite best suits your needs.

Isotropic Graphite vs Anisotropic Graphite Infographic

materialdif.com

materialdif.com