Graphite crucibles offer superior thermal conductivity and resistance to thermal shock compared to carbon crucibles, making them ideal for applications requiring rapid heating and cooling cycles. Carbon crucibles, often made from amorphous carbon materials, provide excellent chemical resistance and high-temperature stability but generally have lower thermal conductivity than graphite. Choosing between graphite and carbon crucibles depends on the specific requirements for temperature control, durability, and chemical exposure in the intended metallurgical or chemical processes.

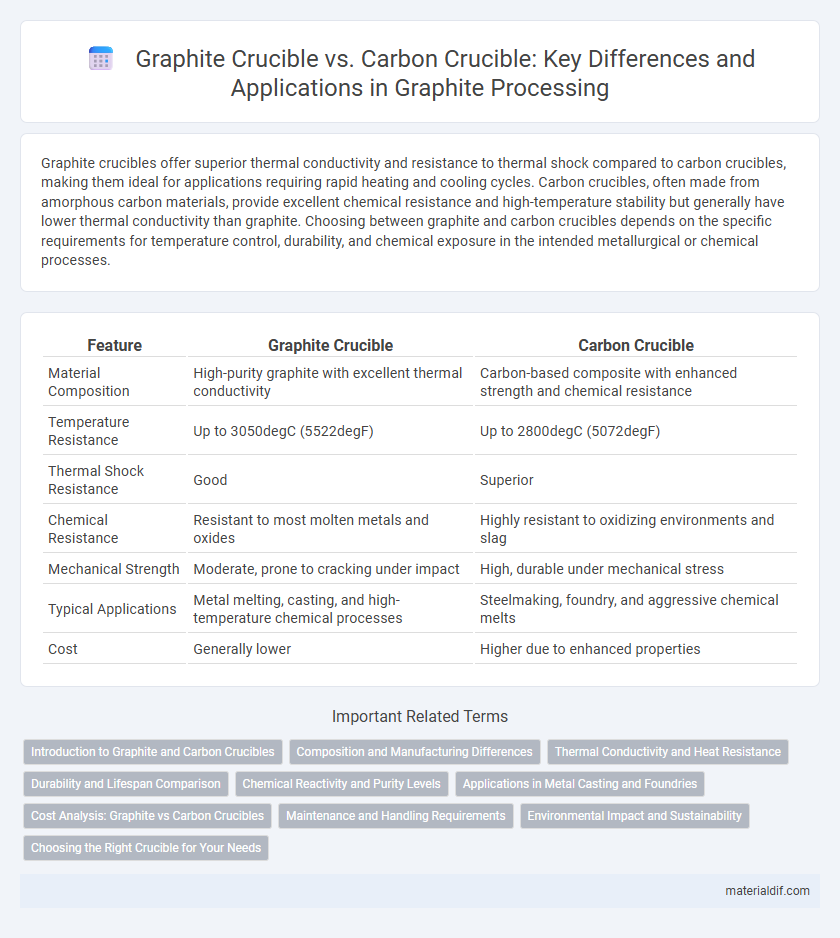

Table of Comparison

| Feature | Graphite Crucible | Carbon Crucible |

|---|---|---|

| Material Composition | High-purity graphite with excellent thermal conductivity | Carbon-based composite with enhanced strength and chemical resistance |

| Temperature Resistance | Up to 3050degC (5522degF) | Up to 2800degC (5072degF) |

| Thermal Shock Resistance | Good | Superior |

| Chemical Resistance | Resistant to most molten metals and oxides | Highly resistant to oxidizing environments and slag |

| Mechanical Strength | Moderate, prone to cracking under impact | High, durable under mechanical stress |

| Typical Applications | Metal melting, casting, and high-temperature chemical processes | Steelmaking, foundry, and aggressive chemical melts |

| Cost | Generally lower | Higher due to enhanced properties |

Introduction to Graphite and Carbon Crucibles

Graphite crucibles are made from crystalline carbon with excellent thermal conductivity and resistance to thermal shock, making them ideal for high-temperature metal melting processes. Carbon crucibles, often composed of amorphous carbon or carbon composites, offer superior chemical resistance and durability under varied industrial conditions. Both crucible types provide efficient heat distribution but differ in structure, with graphite crucibles favored for their machinability and carbon crucibles for their robustness in corrosive environments.

Composition and Manufacturing Differences

Graphite crucibles consist mainly of carbon atoms arranged in a crystalline lattice, providing superior thermal conductivity and resistance to thermal shock compared to carbon crucibles, which are typically made from amorphous carbon or a blend of carbon materials. Manufacturing of graphite crucibles involves high-temperature baking and graphitization processes that enhance purity and structural integrity, whereas carbon crucibles are produced through carbonization of organic binders and materials at lower temperatures, resulting in less uniformity and mechanical strength. These compositional and manufacturing distinctions lead to graphite crucibles offering better performance in high-temperature metal melting and chemical resistance applications.

Thermal Conductivity and Heat Resistance

Graphite crucibles exhibit superior thermal conductivity, typically around 120-160 W/m*K, allowing them to heat uniformly and cool rapidly compared to carbon crucibles, which usually have lower thermal conductivity near 30-50 W/m*K. In terms of heat resistance, graphite crucibles can withstand temperatures up to 3000degC due to their crystalline carbon structure, whereas carbon crucibles generally tolerate maximum temperatures around 2100degC. This makes graphite crucibles highly suitable for high-temperature applications requiring rapid thermal cycling and excellent heat retention.

Durability and Lifespan Comparison

Graphite crucibles exhibit superior thermal shock resistance and maintain structural integrity at extremely high temperatures, resulting in longer lifespans compared to carbon crucibles. Carbon crucibles, while effective in heat retention, tend to degrade faster under prolonged exposure to corrosive materials and extreme heat cycles. The enhanced durability of graphite crucibles makes them a preferred choice for high-temperature industrial processes requiring consistent performance and extended service life.

Chemical Reactivity and Purity Levels

Graphite crucibles exhibit low chemical reactivity and high purity levels, making them suitable for melting reactive metals and alloys without contamination risks. Carbon crucibles, while offering good thermal conductivity, can introduce impurities due to their higher chemical reactivity, especially at elevated temperatures. Graphite's inert nature ensures superior chemical stability and purity retention, critical for processes demanding minimal contamination.

Applications in Metal Casting and Foundries

Graphite crucibles offer superior thermal conductivity and resistance to thermal shock, making them ideal for high-temperature metal casting applications such as aluminum, copper, and precious metals foundries. Carbon crucibles, while cost-effective and durable, are better suited for melting non-ferrous metals and alloys with moderate temperature requirements due to their lower thermal stability. Foundries prioritize graphite crucibles for precision casting and high-volume production processes because of their ability to maintain consistent temperatures and resist chemical corrosion.

Cost Analysis: Graphite vs Carbon Crucibles

Graphite crucibles generally offer higher thermal conductivity and longer lifespan compared to carbon crucibles, resulting in better cost-efficiency over time despite a higher initial price. Carbon crucibles, while cheaper upfront, tend to wear out faster and require more frequent replacements, increasing long-term operational costs. Evaluating total cost of ownership reveals that graphite crucibles provide superior value for industries requiring high-temperature stability and durability.

Maintenance and Handling Requirements

Graphite crucibles require careful handling due to their brittleness and susceptibility to thermal shock, necessitating gradual temperature changes to prevent cracking. Carbon crucibles, while more robust against mechanical stress, demand protection from oxidation at high temperatures through protective atmospheres or coatings. Both types benefit from regular inspection for wear and surface integrity to ensure longevity and maintain optimal performance in metallurgical processes.

Environmental Impact and Sustainability

Graphite crucibles exhibit lower environmental impact compared to carbon crucibles due to their higher thermal efficiency, which reduces energy consumption during metal melting processes. The manufacturing of graphite crucibles involves sustainable sourcing from natural graphite, leading to less carbon footprint than carbon crucibles made from petroleum-derived materials. Additionally, graphite crucibles have better recyclability, enhancing sustainability efforts in foundry and metallurgical industries.

Choosing the Right Crucible for Your Needs

Graphite crucibles offer excellent thermal conductivity and resistance to thermal shock, making them ideal for melting non-ferrous metals like gold, silver, and aluminum. Carbon crucibles provide superior chemical resistance and are suited for high-temperature applications involving corrosive materials or alloys. Selecting the right crucible depends on factors like the melting temperature, type of metal, and chemical environment to ensure durability and efficient heat transfer.

Graphite Crucible vs Carbon Crucible Infographic

materialdif.com

materialdif.com