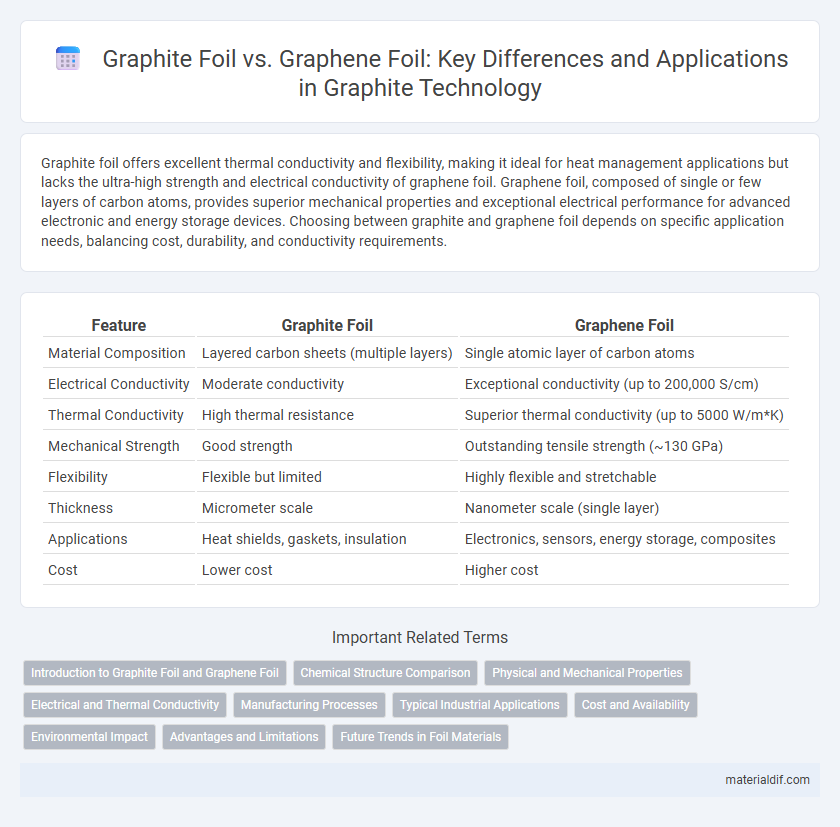

Graphite foil offers excellent thermal conductivity and flexibility, making it ideal for heat management applications but lacks the ultra-high strength and electrical conductivity of graphene foil. Graphene foil, composed of single or few layers of carbon atoms, provides superior mechanical properties and exceptional electrical performance for advanced electronic and energy storage devices. Choosing between graphite and graphene foil depends on specific application needs, balancing cost, durability, and conductivity requirements.

Table of Comparison

| Feature | Graphite Foil | Graphene Foil |

|---|---|---|

| Material Composition | Layered carbon sheets (multiple layers) | Single atomic layer of carbon atoms |

| Electrical Conductivity | Moderate conductivity | Exceptional conductivity (up to 200,000 S/cm) |

| Thermal Conductivity | High thermal resistance | Superior thermal conductivity (up to 5000 W/m*K) |

| Mechanical Strength | Good strength | Outstanding tensile strength (~130 GPa) |

| Flexibility | Flexible but limited | Highly flexible and stretchable |

| Thickness | Micrometer scale | Nanometer scale (single layer) |

| Applications | Heat shields, gaskets, insulation | Electronics, sensors, energy storage, composites |

| Cost | Lower cost | Higher cost |

Introduction to Graphite Foil and Graphene Foil

Graphite foil consists of multiple layers of graphene sheets stacked together, offering high thermal conductivity and electrical conductivity with flexibility and chemical stability. Graphene foil, composed of a single or few layers of graphene, exhibits exceptional mechanical strength, superior electrical conductivity, and remarkable thermal properties at an atomic thickness. Both materials find applications in electronics, energy storage, and thermal management due to their unique carbon-based structures and conductivity profiles.

Chemical Structure Comparison

Graphite foil consists of multiple layers of hexagonally arranged carbon atoms bonded by weak van der Waals forces, allowing easy layer sliding, whereas graphene foil is a single atom-thick sheet of carbon atoms with sp2 hybridization forming a robust and highly conductive planar hexagonal lattice. The chemical structure of graphene enables superior electrical and thermal conductivity compared to the multilayered graphite foil, which has thicker, stacked carbon layers. Graphene's monolayer configuration maximizes surface area and mechanical strength, fundamentally differentiating its chemical and physical properties from graphite foil.

Physical and Mechanical Properties

Graphite foil exhibits high thermal conductivity and excellent chemical resistance, making it suitable for heat management applications, but its mechanical strength is limited due to its layered structure. Graphene foil, composed of single or few layers of carbon atoms, offers superior tensile strength and flexibility while maintaining excellent electrical conductivity and thermal properties, surpassing graphite foil significantly. The mechanical resilience and lightweight nature of graphene foil enable advanced applications in flexible electronics and composite materials where enhanced durability and performance are required.

Electrical and Thermal Conductivity

Graphite foil exhibits high electrical conductivity due to its layered structure allowing electron mobility but suffers from lower thermal conductivity compared to graphene. Graphene foil, composed of a single layer of carbon atoms arranged in a hexagonal lattice, offers exceptional electrical conductivity surpassing graphite, along with superior thermal conductivity reaching values above 5000 W/mK. The enhanced electron transport and heat dissipation properties of graphene foil make it ideal for advanced electronic and thermal management applications.

Manufacturing Processes

Graphite foil is typically manufactured through exfoliation and compression of natural graphite, involving processes like chemical intercalation and thermal expansion to create thin, flexible sheets. In contrast, graphene foil production often employs chemical vapor deposition (CVD) on metal substrates, resulting in single-layer or few-layer graphene films with superior electrical and mechanical properties. The complexity and cost of graphene foil manufacturing remain higher compared to graphite foil due to advanced synthesis techniques and substrate removal steps.

Typical Industrial Applications

Graphite foil is widely utilized in thermal management applications such as heat shields, gaskets, and insulation in aerospace and automotive industries due to its excellent thermal conductivity and chemical resistance. Graphene foil, offering superior electrical conductivity and mechanical strength, is increasingly adopted in flexible electronics, advanced sensors, and energy storage devices like supercapacitors and batteries. Both materials play crucial roles in industrial manufacturing, with graphite foil preferred for high-temperature environments and graphene foil driving innovation in next-generation electronic components.

Cost and Availability

Graphite foil is generally more cost-effective and widely available compared to graphene foil, which remains expensive due to complex production methods and limited large-scale manufacturing. The abundance of natural graphite resources enables mass production of graphite foil, ensuring steady supply chains. In contrast, graphene foil's high demand in advanced electronics drives up prices and limits its accessibility for broad industrial use.

Environmental Impact

Graphite foil typically has a lower environmental impact during production compared to graphene foil, mainly due to simpler manufacturing processes and less energy consumption. Graphene foil, while offering superior mechanical and electrical properties, demands more intensive chemical treatments and energy use, resulting in higher carbon emissions and resource depletion. Lifecycle assessments highlight that scaling graphene production sustainably is crucial to minimizing its ecological footprint relative to conventional graphite foil.

Advantages and Limitations

Graphite foil offers excellent thermal conductivity and flexibility, making it ideal for heat dissipation in electronic and industrial applications, but it has a lower electrical conductivity compared to graphene foil. Graphene foil provides superior mechanical strength, higher electrical and thermal conductivity, and exceptional chemical stability, yet its production cost and scalability remain significant limitations. Both materials serve critical roles in advanced technology, with graphite foil preferred for cost-effective heat management and graphene foil favored for high-performance electronic and energy storage solutions.

Future Trends in Foil Materials

Graphene foil is rapidly emerging as a superior alternative to graphite foil due to its exceptional electrical conductivity, mechanical strength, and thermal stability. Future trends in foil materials emphasize the integration of graphene for advanced applications in flexible electronics, energy storage devices, and thermal management systems. Innovations in scalable manufacturing techniques are expected to accelerate the commercial adoption of graphene foils, outperforming traditional graphite-based materials.

Graphite foil vs Graphene foil Infographic

materialdif.com

materialdif.com