Refractory graphite is engineered to withstand extreme temperatures and chemical corrosion, making it ideal for high-temperature industrial applications such as furnace linings and molds. Conductive graphite, on the other hand, is prized for its excellent electrical conductivity, used in batteries, electrodes, and electronic devices. Understanding the distinct thermal and electrical properties of refractory versus conductive graphite ensures optimal performance in specialized manufacturing processes.

Table of Comparison

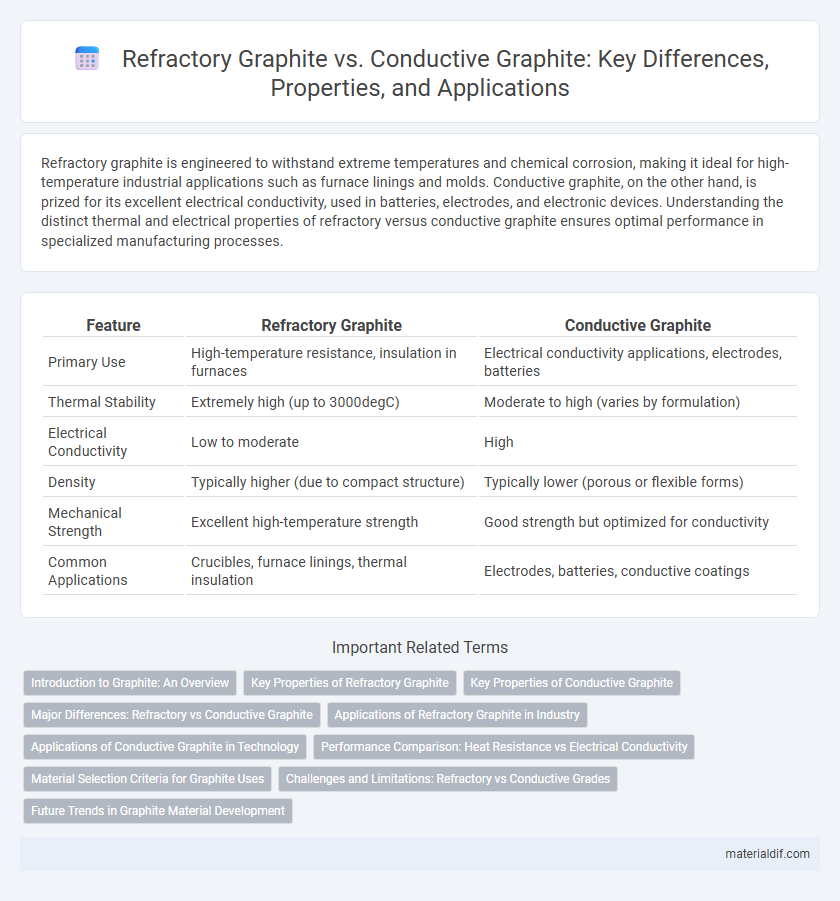

| Feature | Refractory Graphite | Conductive Graphite |

|---|---|---|

| Primary Use | High-temperature resistance, insulation in furnaces | Electrical conductivity applications, electrodes, batteries |

| Thermal Stability | Extremely high (up to 3000degC) | Moderate to high (varies by formulation) |

| Electrical Conductivity | Low to moderate | High |

| Density | Typically higher (due to compact structure) | Typically lower (porous or flexible forms) |

| Mechanical Strength | Excellent high-temperature strength | Good strength but optimized for conductivity |

| Common Applications | Crucibles, furnace linings, thermal insulation | Electrodes, batteries, conductive coatings |

Introduction to Graphite: An Overview

Refractory graphite is characterized by its high thermal stability and resistance to chemical attack, making it essential for applications in extreme environments such as crucibles and furnace linings. Conductive graphite, in contrast, excels in electrical conductivity and is widely used in electrodes, batteries, and electronic devices. Understanding the unique properties of refractory versus conductive graphite is crucial for selecting the appropriate type for industrial processes and technological applications.

Key Properties of Refractory Graphite

Refractory graphite features exceptional thermal stability, high melting point above 3600degC, and excellent chemical resistance, making it ideal for high-temperature applications. Its low thermal expansion and superior mechanical strength ensure durability in harsh environments, unlike conductive graphite, which prioritizes electrical conductivity. These key properties enable refractory graphite to withstand extreme heat and corrosive conditions in industries such as aerospace and metallurgy.

Key Properties of Conductive Graphite

Conductive graphite exhibits exceptional electrical conductivity and thermal stability, making it crucial for applications in electrical electrodes, batteries, and fuel cells. Its low electrical resistivity, coupled with high purity and fine crystalline structure, enhances electron mobility and ensures efficient current flow. The material also features excellent chemical resistance and mechanical strength, supporting durability in harsh operational environments.

Major Differences: Refractory vs Conductive Graphite

Refractory graphite exhibits exceptional heat resistance and structural stability at high temperatures, making it ideal for use in furnace linings and high-temperature molds. Conductive graphite, on the other hand, is characterized by high electrical conductivity and is widely used in electrodes, batteries, and electronic components. The major difference lies in refractory graphite's thermal resilience versus conductive graphite's superior electrical properties.

Applications of Refractory Graphite in Industry

Refractory graphite is primarily used in high-temperature industrial applications, including the production of crucibles, electrodes for electric arc furnaces, and heat shields due to its excellent thermal stability and resistance to chemical attack. This type of graphite is essential in metallurgy, where it withstands extreme temperatures for smelting and refining metals like steel and aluminum. Its superior mechanical strength and oxidation resistance make refractory graphite indispensable for continuous casting molds and furnace linings in manufacturing processes.

Applications of Conductive Graphite in Technology

Conductive graphite finds extensive applications in technology, particularly in the manufacturing of electrodes for electric arc furnaces and lithium-ion batteries due to its excellent electrical conductivity. Its role in electromagnetic shielding materials ensures enhanced performance in electronic devices by minimizing interference. Additionally, conductive graphite is used in fuel cells and sensors, leveraging its stability and conductivity to improve efficiency and sensitivity.

Performance Comparison: Heat Resistance vs Electrical Conductivity

Refractory graphite excels in heat resistance withstanding temperatures up to 3000degC, making it ideal for high-temperature industrial applications such as furnace linings and heat exchangers. Conductive graphite offers superior electrical conductivity, reaching up to 10^4 S/m, essential for electrodes and electrical contacts where efficient current flow is critical. The choice between refractory and conductive graphite depends on whether thermal stability or electrical performance is the primary requirement in specific industrial processes.

Material Selection Criteria for Graphite Uses

Material selection criteria for refractory graphite prioritize high thermal stability, resistance to oxidation, and mechanical strength at elevated temperatures, making it ideal for furnace linings and aerospace components. Conductive graphite is chosen based on its electrical conductivity, purity, and machinability, which are critical for applications in batteries, electrodes, and electronic devices. Understanding the specific thermal, electrical, and mechanical requirements ensures the optimal use of graphite types in industrial and technological environments.

Challenges and Limitations: Refractory vs Conductive Grades

Refractory graphite faces challenges such as limited electrical conductivity and increased brittleness at high temperatures, restricting its use in applications requiring efficient heat dissipation. Conductive graphite offers superior electrical and thermal conductivity but suffers from lower mechanical strength and reduced resistance to thermal shock. These limitations require careful material selection based on specific application needs in industries like metallurgy and electronics.

Future Trends in Graphite Material Development

Refractory graphite, characterized by high thermal stability and resistance to chemical attack, is increasingly being engineered with enhanced purity and microstructure for next-generation aerospace and nuclear applications. Conductive graphite is evolving through innovations in nanoscale modifications and hybrid composites to significantly improve electrical conductivity and mechanical flexibility for use in advanced batteries and flexible electronics. Future developments in graphite materials emphasize sustainable synthesis methods and multifunctional performance to meet the growing demand in energy storage, electronics, and high-temperature industrial processes.

Refractory Graphite vs Conductive Graphite Infographic

materialdif.com

materialdif.com