Graphite electrodes offer superior electrical conductivity and thermal resistance compared to carbon electrodes, making them ideal for high-temperature applications like electric arc furnaces. Carbon electrodes, while less conductive, provide greater mechanical strength and are typically more cost-effective for lower-temperature uses. Choosing between graphite and carbon electrodes depends on the specific industrial requirements, balancing performance and budget considerations.

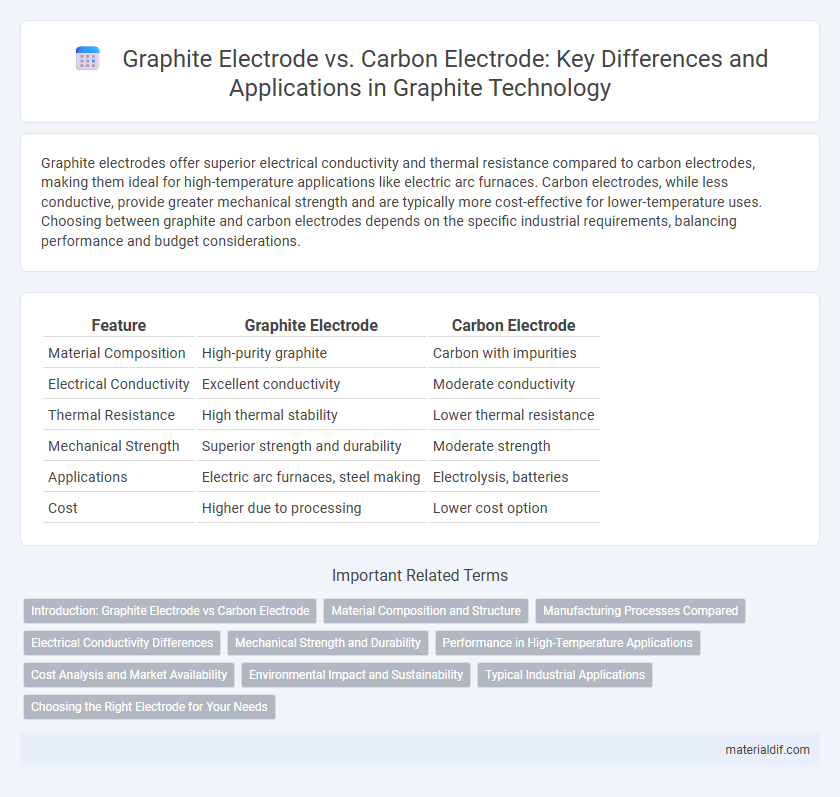

Table of Comparison

| Feature | Graphite Electrode | Carbon Electrode |

|---|---|---|

| Material Composition | High-purity graphite | Carbon with impurities |

| Electrical Conductivity | Excellent conductivity | Moderate conductivity |

| Thermal Resistance | High thermal stability | Lower thermal resistance |

| Mechanical Strength | Superior strength and durability | Moderate strength |

| Applications | Electric arc furnaces, steel making | Electrolysis, batteries |

| Cost | Higher due to processing | Lower cost option |

Introduction: Graphite Electrode vs Carbon Electrode

Graphite electrodes are primarily composed of crystalline carbon structures with high purity and excellent electrical conductivity, making them ideal for electric arc furnace applications in steel manufacturing. Carbon electrodes, by contrast, may include a broader range of carbon forms with varying conductivity and strength, often used in less demanding industrial processes. Understanding the fundamental differences in material composition and performance characteristics is essential for selecting the appropriate electrode type for high-temperature, high-current environments.

Material Composition and Structure

Graphite electrodes are primarily composed of high-purity carbon with a crystalline graphite structure, offering superior electrical conductivity and thermal resistance compared to carbon electrodes, which generally consist of amorphous carbon materials with lower purity. The graphite's hexagonal crystal lattice provides enhanced mechanical strength and oxidation resistance, making it suitable for high-temperature applications such as electric arc furnaces. Carbon electrodes tend to have a more random structure with higher impurity content, resulting in lower conductivity and shorter service life in industrial processes.

Manufacturing Processes Compared

Graphite electrodes are manufactured through the calcination of petroleum coke and pitch, followed by graphitization at temperatures above 2500degC to enhance conductivity and thermal resistance. Carbon electrodes, in contrast, typically undergo baking at lower temperatures around 1200degC and do not reach the graphite stage, resulting in lower electrical conductivity and mechanical strength. The graphitization process in graphite electrodes provides superior performance in electric arc furnaces compared to the more basic manufacturing of carbon electrodes.

Electrical Conductivity Differences

Graphite electrodes exhibit significantly higher electrical conductivity compared to carbon electrodes due to their crystalline structure, which allows for more efficient electron flow. The anisotropic nature of graphite enhances its conductivity along the basal planes, whereas carbon electrodes, often amorphous or less ordered, show lower conductivity and higher electrical resistance. This difference makes graphite electrodes the preferred choice in electric arc furnaces and other high-current applications requiring superior electrical performance.

Mechanical Strength and Durability

Graphite electrodes exhibit superior mechanical strength and durability compared to carbon electrodes due to their higher purity and uniform crystalline structure, which enhances resistance to thermal shock and mechanical stress. The optimized manufacturing process of graphite electrodes results in improved density and reduced porosity, contributing to longer service life in electric arc furnace applications. Carbon electrodes, while effective, generally lack the same level of structural integrity and wear resistance, leading to more frequent replacement and higher operational costs.

Performance in High-Temperature Applications

Graphite electrodes exhibit superior performance in high-temperature applications due to their higher thermal conductivity and resistance to thermal shock compared to carbon electrodes. The crystalline structure of graphite allows for better electrical conductivity and durability under extreme temperatures, making it ideal for electric arc furnaces and steelmaking processes. Conversely, carbon electrodes tend to degrade faster and show reduced efficiency in maintaining consistent electrical performance in intense thermal environments.

Cost Analysis and Market Availability

Graphite electrodes generally cost more than carbon electrodes due to their superior conductivity and durability in electric arc furnace applications, impacting overall production expenses. Market availability of graphite electrodes is tighter, especially during periods of high steel production, resulting in price volatility compared to the more readily available carbon electrodes. Cost analysis reveals that the initial investment in graphite electrodes is offset by their longer lifespan and better performance, making them economically favorable in the long term despite higher upfront costs.

Environmental Impact and Sustainability

Graphite electrodes exhibit lower environmental impact compared to traditional carbon electrodes due to their higher energy efficiency and longer lifespan, reducing the frequency of replacements and raw material consumption. The manufacturing process of graphite electrodes generates fewer greenhouse gas emissions and utilizes more sustainable feedstock sources, aligning with global carbon reduction goals. Enhanced recyclability of graphite electrodes further contributes to sustainability by minimizing waste and promoting circular economy practices in industrial applications.

Typical Industrial Applications

Graphite electrodes are predominantly used in electric arc furnaces for steelmaking due to their high electrical conductivity and thermal resistance, enabling efficient melting of scrap metal. Carbon electrodes find typical applications in metallurgical processes such as aluminum smelting and chemical synthesis, where their resistance to chemical corrosion is crucial. Both electrode types serve essential roles in heavy industries, but graphite's superior mechanical strength and conductivity make it the preferred choice for high-temperature, high-current environments.

Choosing the Right Electrode for Your Needs

Graphite electrodes offer superior electrical conductivity and thermal resistance, making them ideal for electric arc furnace applications, while carbon electrodes provide cost-effective solutions for lower temperature processes. When choosing the right electrode, consider factors such as operational temperature, electrical efficiency, and durability requirements specific to your industrial process. Optimal electrode selection enhances performance, reduces energy consumption, and extends equipment lifespan in metallurgical and chemical industries.

Graphite Electrode vs Carbon Electrode Infographic

materialdif.com

materialdif.com