Expandable graphite is treated with acids to increase its volume when heated, making it ideal for applications requiring thermal expansion, such as fire retardants and sealing materials. Flake graphite, in contrast, retains its original layered structure and is valued for its high purity and lubricating properties, commonly used in batteries, brake linings, and refractories. Both forms offer unique advantages based on particle size and structural characteristics, influencing their selection in industrial applications.

Table of Comparison

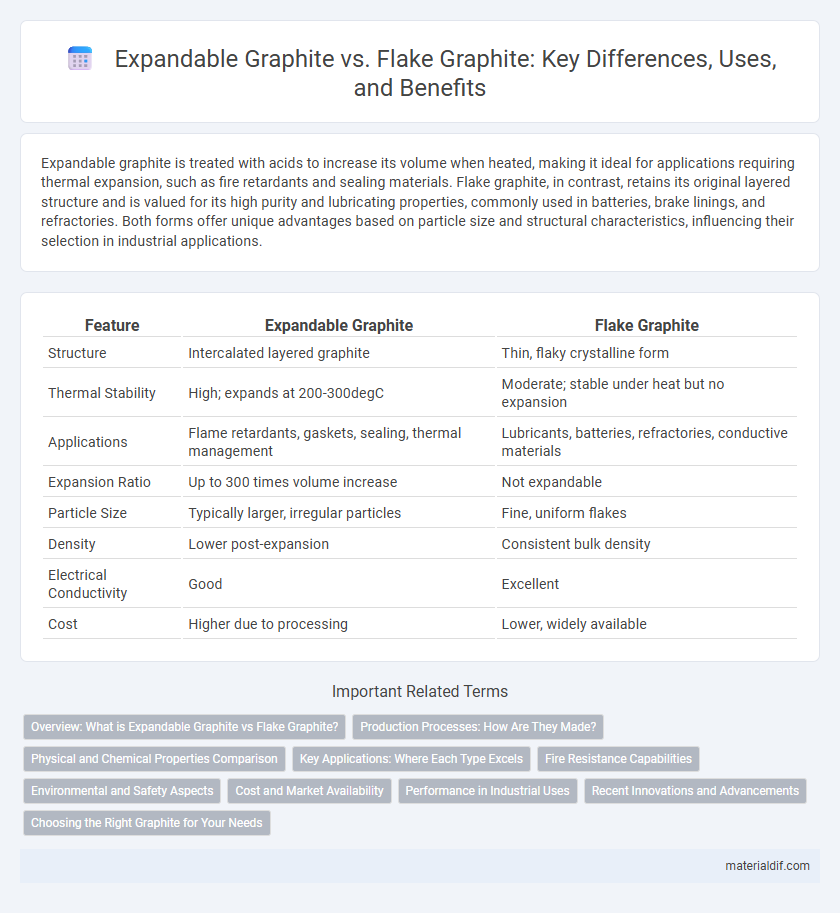

| Feature | Expandable Graphite | Flake Graphite |

|---|---|---|

| Structure | Intercalated layered graphite | Thin, flaky crystalline form |

| Thermal Stability | High; expands at 200-300degC | Moderate; stable under heat but no expansion |

| Applications | Flame retardants, gaskets, sealing, thermal management | Lubricants, batteries, refractories, conductive materials |

| Expansion Ratio | Up to 300 times volume increase | Not expandable |

| Particle Size | Typically larger, irregular particles | Fine, uniform flakes |

| Density | Lower post-expansion | Consistent bulk density |

| Electrical Conductivity | Good | Excellent |

| Cost | Higher due to processing | Lower, widely available |

Overview: What is Expandable Graphite vs Flake Graphite?

Expandable graphite is a form of graphite that has been chemically treated to increase its interlayer spacing, allowing it to expand significantly when exposed to heat. Flake graphite consists of natural crystalline flakes of carbon that exhibit a layered structure, commonly used in applications requiring high thermal conductivity and lubricity. The primary difference lies in expandable graphite's ability to expand and form a protective char in fire retardant applications, whereas flake graphite is valued for its purity and physical properties in industrial uses.

Production Processes: How Are They Made?

Expandable graphite is produced by intercalating natural flake graphite with acids such as sulfuric or nitric acid, followed by rapid heating which causes expansion. Flake graphite is extracted through mining and then processed via flotation to separate the flakes from unwanted minerals, resulting in purified graphite flakes. While flake graphite retains its natural layered structure, expandable graphite undergoes chemical treatment and thermal exfoliation to achieve its unique, expandable form.

Physical and Chemical Properties Comparison

Expandable graphite exhibits a layered, worm-like structure that expands significantly when heated, making it ideal for fire retardant applications, whereas flake graphite maintains a rigid, flat morphology with high electrical and thermal conductivity. Chemically, both forms consist primarily of carbon with a hexagonal crystal lattice, but expandable graphite contains intercalated acid molecules that enable rapid expansion upon heating, unlike flake graphite which remains chemically inert under similar conditions. The density of expandable graphite is lower due to its porous, expanded form, while flake graphite typically has higher density and superior lubricity owing to its compact crystalline layers.

Key Applications: Where Each Type Excels

Expandable graphite is highly effective in fire retardant materials, batteries, and sealing applications due to its ability to expand when heated, providing excellent thermal insulation and flame resistance. Flake graphite excels in lubricants, refractory materials, and conductive powders, offering superior electrical conductivity and mechanical strength. Each type's unique structure determines its suitability for specific industrial uses, optimizing performance in thermal management or electrical conductivity roles.

Fire Resistance Capabilities

Expandable graphite exhibits superior fire resistance capabilities compared to flake graphite due to its ability to expand when exposed to high temperatures, forming an insulating char layer that inhibits heat transfer and flame spread. This property makes expandable graphite highly effective in intumescent coatings and fireproofing applications, where enhanced thermal insulation and durability are critical. Conversely, flake graphite lacks significant expansion under fire conditions, resulting in lower fire resistance performance.

Environmental and Safety Aspects

Expandable graphite offers superior fire retardant properties due to its ability to expand and form an insulating layer, reducing environmental hazards from toxic fumes. Flake graphite, while less effective in fire resistance, presents lower risks during handling as it produces minimal dust, contributing to workplace safety. Both forms require careful management to prevent environmental contamination, but expandable graphite's expansion process mandates stricter control measures to avoid airborne particles and inhalation risks.

Cost and Market Availability

Expandable graphite generally costs more than flake graphite due to the additional processing required to create its unique layered structure. Flake graphite enjoys broader market availability and lower prices, making it the preferred choice for large-scale industrial applications. The price difference is influenced by demand dynamics, processing complexity, and purity levels, with expandable graphite favored in niche applications like fire retardants and thermal management.

Performance in Industrial Uses

Expandable graphite exhibits superior thermal conductivity and chemical stability compared to flake graphite, making it ideal for high-temperature industrial applications such as fire retardants and heat exchangers. Flake graphite offers better electrical conductivity and lubricity, which enhances performance in battery anodes and lubricants. The choice between expandable and flake graphite depends on the specific industrial requirements for thermal resilience versus electrical and mechanical properties.

Recent Innovations and Advancements

Recent innovations in expandable graphite have focused on enhancing its exfoliation efficiency and thermal stability, leveraging nanostructured coatings and advanced intercalation techniques for superior performance in fire retardants and conductive materials. Flake graphite advancements prioritize purity and size uniformity, utilizing novel flotation and chemical treatment methods to improve its applicability in batteries and lubricants. These developments highlight a shift towards tailored properties in graphite forms, optimizing their functionality for high-tech industrial applications.

Choosing the Right Graphite for Your Needs

Expandable graphite offers superior thermal insulation and flame-retardant properties, making it ideal for applications in fireproofing and sealing materials. Flake graphite, characterized by its high electrical conductivity and lubricating properties, is preferred in battery production and industrial lubricants. Selecting the right graphite depends on specific performance requirements such as thermal stability, electrical conductivity, and mechanical flexibility.

Expandable Graphite vs Flake Graphite Infographic

materialdif.com

materialdif.com