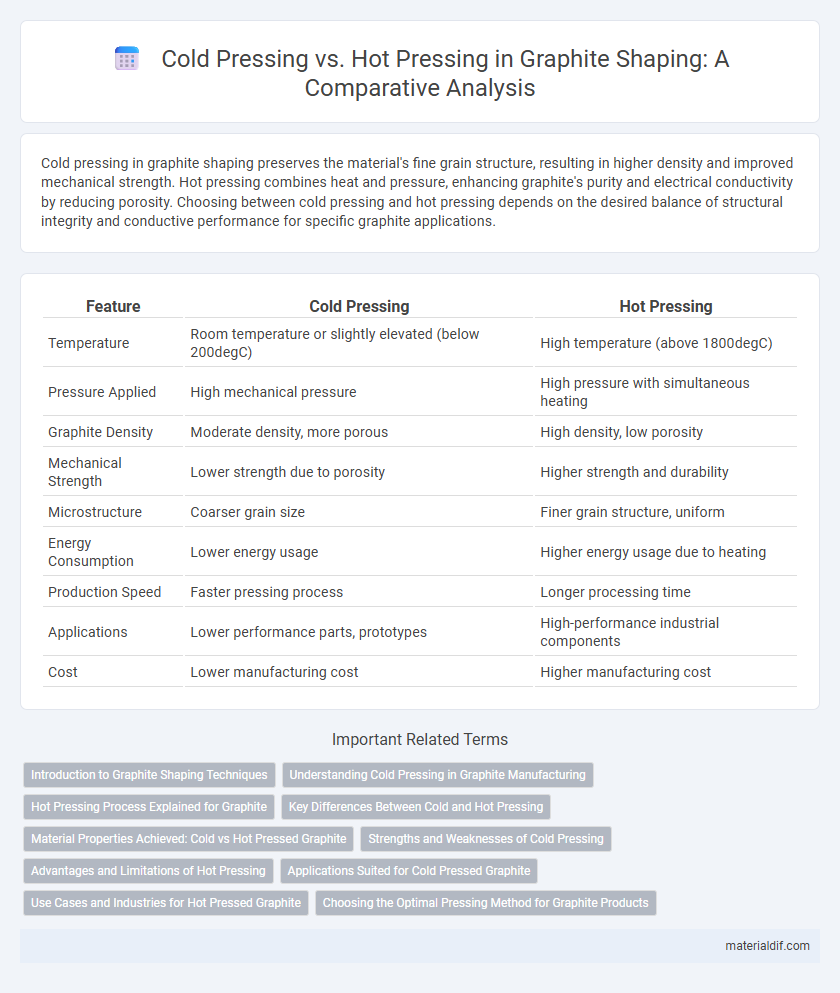

Cold pressing in graphite shaping preserves the material's fine grain structure, resulting in higher density and improved mechanical strength. Hot pressing combines heat and pressure, enhancing graphite's purity and electrical conductivity by reducing porosity. Choosing between cold pressing and hot pressing depends on the desired balance of structural integrity and conductive performance for specific graphite applications.

Table of Comparison

| Feature | Cold Pressing | Hot Pressing |

|---|---|---|

| Temperature | Room temperature or slightly elevated (below 200degC) | High temperature (above 1800degC) |

| Pressure Applied | High mechanical pressure | High pressure with simultaneous heating |

| Graphite Density | Moderate density, more porous | High density, low porosity |

| Mechanical Strength | Lower strength due to porosity | Higher strength and durability |

| Microstructure | Coarser grain size | Finer grain structure, uniform |

| Energy Consumption | Lower energy usage | Higher energy usage due to heating |

| Production Speed | Faster pressing process | Longer processing time |

| Applications | Lower performance parts, prototypes | High-performance industrial components |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

Introduction to Graphite Shaping Techniques

Cold pressing in graphite shaping involves compressing graphite powder at room temperature, producing components with high mechanical strength and fine microstructure, ideal for applications requiring precise dimensional control. Hot pressing applies heat and pressure simultaneously, enhancing density and electrical conductivity by reducing porosity and promoting grain bonding, commonly used in manufacturing high-performance graphite electrodes and molds. Both techniques optimize graphite's structural properties but differ in thermal impact and material characteristics, influencing the choice based on the intended industrial application.

Understanding Cold Pressing in Graphite Manufacturing

Cold pressing in graphite manufacturing involves compressing graphite powders at room temperature to form dense, uniform shapes with minimal thermal stress, preserving the fine microstructure and enhancing electrical conductivity. This method reduces oxidation and contamination risks compared to hot pressing, ensuring high purity and consistent mechanical properties critical for applications like electrodes and refractory components. Cold pressing enables precise control over the final product's porosity and density, optimizing performance in high-temperature industrial processes.

Hot Pressing Process Explained for Graphite

Hot pressing in graphite shaping involves simultaneously applying heat and pressure to graphite powder within a mold, promoting densification and enhancing mechanical properties. This process enables the production of components with higher density, improved strength, and superior thermal conductivity compared to cold pressing. The controlled temperature and pressure conditions during hot pressing facilitate particle bonding and reduce porosity, resulting in high-performance graphite materials used in applications such as electrodes, refractories, and advanced engineering parts.

Key Differences Between Cold and Hot Pressing

Cold pressing in graphite shaping involves compressing graphite powder at room temperature, resulting in lower density and reduced mechanical strength compared to hot pressing. Hot pressing applies heat and pressure simultaneously, enhancing densification, improving grain bonding, and yielding higher strength and thermal conductivity in the final graphite product. Temperature control during hot pressing is crucial for optimizing microstructure and minimizing defects, leading to superior performance in applications requiring high durability and thermal stability.

Material Properties Achieved: Cold vs Hot Pressed Graphite

Cold pressing graphite results in higher density and improved mechanical strength due to uniform particle compaction, enhancing electrical conductivity and thermal resistance. Hot pressing combines heat and pressure, promoting grain growth and bonding, which increases toughness and reduces porosity, leading to superior thermal shock resistance. The choice between cold and hot pressing directly influences the microstructure, porosity, and overall performance of graphite components in high-stress applications.

Strengths and Weaknesses of Cold Pressing

Cold pressing in graphite shaping offers enhanced dimensional accuracy and uniform density, making it ideal for precise and complex shapes. However, it results in lower mechanical strength and higher porosity compared to hot pressing, limiting its use in high-stress applications. The process is energy-efficient and cost-effective but requires subsequent heat treatment to improve material properties.

Advantages and Limitations of Hot Pressing

Hot pressing in graphite shaping offers superior density and mechanical strength due to simultaneous application of heat and pressure, resulting in enhanced thermal conductivity and structural integrity compared to cold pressing. The technique enables faster sintering cycles and produces components with fewer defects, making it ideal for high-performance applications like electrodes and heat exchangers. However, hot pressing requires expensive equipment and precise temperature control, limiting its scalability and increasing production costs.

Applications Suited for Cold Pressed Graphite

Cold pressed graphite excels in applications requiring high purity and uniform density, such as electrodes in electric arc furnaces and battery anodes. Its fine grain structure provides superior electrical conductivity and thermal stability, making it ideal for precision components in the electronics and aerospace industries. Industries leveraging wear resistance and corrosion resistance benefit from cold pressed graphite's consistency and mechanical strength.

Use Cases and Industries for Hot Pressed Graphite

Hot pressed graphite is extensively utilized in industries requiring high-density, uniform, and mechanically robust components, such as aerospace, electronics, and automotive sectors. Its use cases include manufacturing heat sinks, electrodes for electric arc furnaces, and precision molds, where superior thermal conductivity and structural integrity are critical. These properties enable hot pressed graphite to perform effectively in environments involving high temperature, pressure, and corrosive materials.

Choosing the Optimal Pressing Method for Graphite Products

Cold pressing preserves graphite's microstructure, resulting in higher density and improved electrical conductivity, ideal for precision applications like electrodes. Hot pressing enhances mechanical strength by combining heat and pressure to promote bonding at the particle level, suitable for high-stress environments such as aerospace components. Selecting between cold and hot pressing depends on balancing the desired thermal stability, mechanical properties, and production cost efficiency for specific graphite product requirements.

Cold Pressing vs Hot Pressing (in Graphite shaping) Infographic

materialdif.com

materialdif.com