Graphite sheets offer superior thermal conductivity and flexibility compared to metal sheets, making them ideal for heat dissipation in electronic devices. Unlike metal sheets, graphite sheets are lightweight, corrosion-resistant, and provide excellent electrical insulation. These properties enhance durability and performance in applications requiring efficient thermal management.

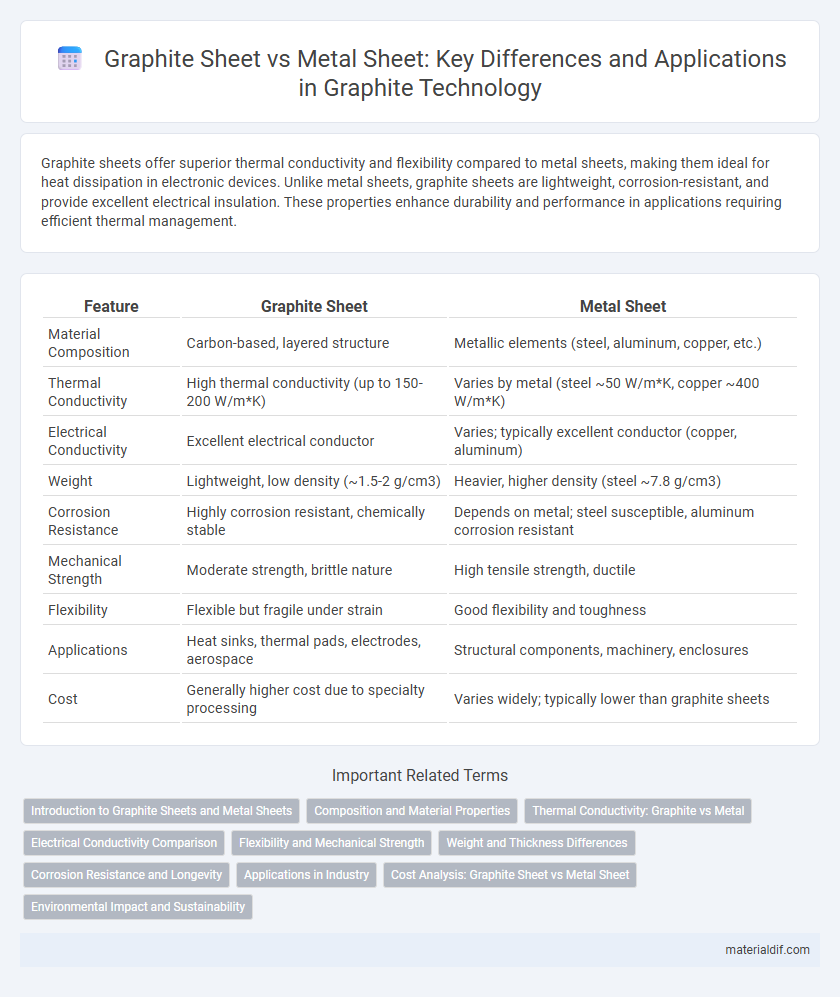

Table of Comparison

| Feature | Graphite Sheet | Metal Sheet |

|---|---|---|

| Material Composition | Carbon-based, layered structure | Metallic elements (steel, aluminum, copper, etc.) |

| Thermal Conductivity | High thermal conductivity (up to 150-200 W/m*K) | Varies by metal (steel ~50 W/m*K, copper ~400 W/m*K) |

| Electrical Conductivity | Excellent electrical conductor | Varies; typically excellent conductor (copper, aluminum) |

| Weight | Lightweight, low density (~1.5-2 g/cm3) | Heavier, higher density (steel ~7.8 g/cm3) |

| Corrosion Resistance | Highly corrosion resistant, chemically stable | Depends on metal; steel susceptible, aluminum corrosion resistant |

| Mechanical Strength | Moderate strength, brittle nature | High tensile strength, ductile |

| Flexibility | Flexible but fragile under strain | Good flexibility and toughness |

| Applications | Heat sinks, thermal pads, electrodes, aerospace | Structural components, machinery, enclosures |

| Cost | Generally higher cost due to specialty processing | Varies widely; typically lower than graphite sheets |

Introduction to Graphite Sheets and Metal Sheets

Graphite sheets are composed of highly ordered carbon layers, offering excellent thermal conductivity, flexibility, and electrical insulation, making them ideal for heat dissipation in electronic devices. Metal sheets, typically made from aluminum or copper, provide superior mechanical strength and electrical conductivity but are heavier and less flexible compared to graphite sheets. The choice between graphite sheets and metal sheets depends on application requirements such as thermal management efficiency, weight constraints, and electrical insulation needs.

Composition and Material Properties

Graphite sheets consist primarily of tightly packed layers of carbon atoms arranged in a hexagonal lattice, providing excellent thermal conductivity, electrical insulation, and chemical stability. Metal sheets are composed of various metallic elements, such as aluminum, copper, or steel, characterized by high mechanical strength, electrical conductivity, and malleability. Graphite sheets exhibit superior heat resistance and dimensional stability compared to metal sheets, which can corrode and deform under extreme conditions.

Thermal Conductivity: Graphite vs Metal

Graphite sheets exhibit exceptional thermal conductivity ranging from 150 to 900 W/m*K, surpassing many metal sheets such as stainless steel (around 15 W/m*K) and aluminum (approximately 205 W/m*K). The anisotropic nature of graphite allows heat to spread rapidly along its planes, making it ideal for efficient thermal management in electronics and high-performance heat dissipation applications. Metal sheets, while conductive, typically suffer from higher weight and corrosion issues, limiting their efficiency compared to lightweight, corrosion-resistant graphite sheets.

Electrical Conductivity Comparison

Graphite sheets exhibit significantly higher electrical conductivity than most metal sheets, with values typically around 10^4 S/m compared to common metals like aluminum or copper, which range from 10^7 S/m but suffer from higher density and weight. The anisotropic nature of graphite allows for superior conductivity along the basal planes, making it ideal for lightweight, flexible electronic applications. Metal sheets, while possessing high conductivity, often face challenges in corrosion resistance and mechanical flexibility that graphite sheets overcome effectively.

Flexibility and Mechanical Strength

Graphite sheets exhibit exceptional flexibility due to their layered atomic structure, allowing them to bend without cracking, unlike metal sheets that tend to deform or fracture under similar stress. Despite their pliability, graphite sheets maintain moderate mechanical strength, making them ideal for applications requiring lightweight durability. Metal sheets offer superior mechanical strength and hardness but lack the same level of flexibility, often resulting in permanent deformation when subjected to bending forces.

Weight and Thickness Differences

Graphite sheets typically offer significantly lower weight compared to metal sheets of similar dimensions, enhancing portability and reducing structural load in applications. They are available in thinner profiles, often starting from fractions of a millimeter, while metal sheets generally require greater thickness to achieve comparable strength and durability. This combination of lightweight and thinness makes graphite sheets advantageous for high-performance industries such as aerospace and electronics where weight-saving is critical.

Corrosion Resistance and Longevity

Graphite sheets exhibit superior corrosion resistance compared to metal sheets due to their inert nature and resistance to chemical reactions, making them ideal for harsh environments. Metal sheets, depending on their alloy composition, can suffer from oxidation and rust, reducing their longevity and requiring frequent maintenance. This inherent durability in graphite sheets translates to longer service life and lower replacement costs in industries exposed to corrosive substances.

Applications in Industry

Graphite sheets exhibit superior thermal conductivity and chemical resistance compared to metal sheets, making them ideal for high-temperature insulation and sealing in aerospace and electronics industries. Metal sheets, preferred for structural applications, offer higher mechanical strength and electrical conductivity, widely used in automotive manufacturing and construction. The unique combination of lightweight flexibility and heat tolerance in graphite sheets drives their adoption in battery technology and semiconductor fabrication.

Cost Analysis: Graphite Sheet vs Metal Sheet

Graphite sheets generally offer a lower material and manufacturing cost compared to metal sheets due to their lightweight and ease of processing, which reduces machining expenses. Metal sheets, particularly those made from stainless steel or aluminum, typically incur higher costs because of raw material prices and energy-intensive fabrication processes. The overall cost-efficiency of graphite sheets makes them an attractive alternative for applications requiring thermal management or electrical conductivity without the weight and expense of metals.

Environmental Impact and Sustainability

Graphite sheets offer a lower environmental impact compared to metal sheets due to their lightweight nature, which reduces energy consumption during transportation and manufacturing. They are also more sustainable as graphite is sourced from abundant natural deposits and can be recycled more easily than metals like aluminum or steel. The reduced carbon footprint and recyclability of graphite sheets contribute significantly to sustainable material choices in industrial and electronic applications.

Graphite sheet vs Metal sheet Infographic

materialdif.com

materialdif.com