Molded graphite offers superior mechanical strength and uniform density, ideal for high-temperature and high-pressure applications in the graphite pet industry. Die-pressed graphite provides precise shape control and enhanced thermal conductivity, making it suitable for intricate or customized graphite pet components. Comparing molded graphite versus die-pressed graphite helps select the optimal material based on specific performance and design requirements.

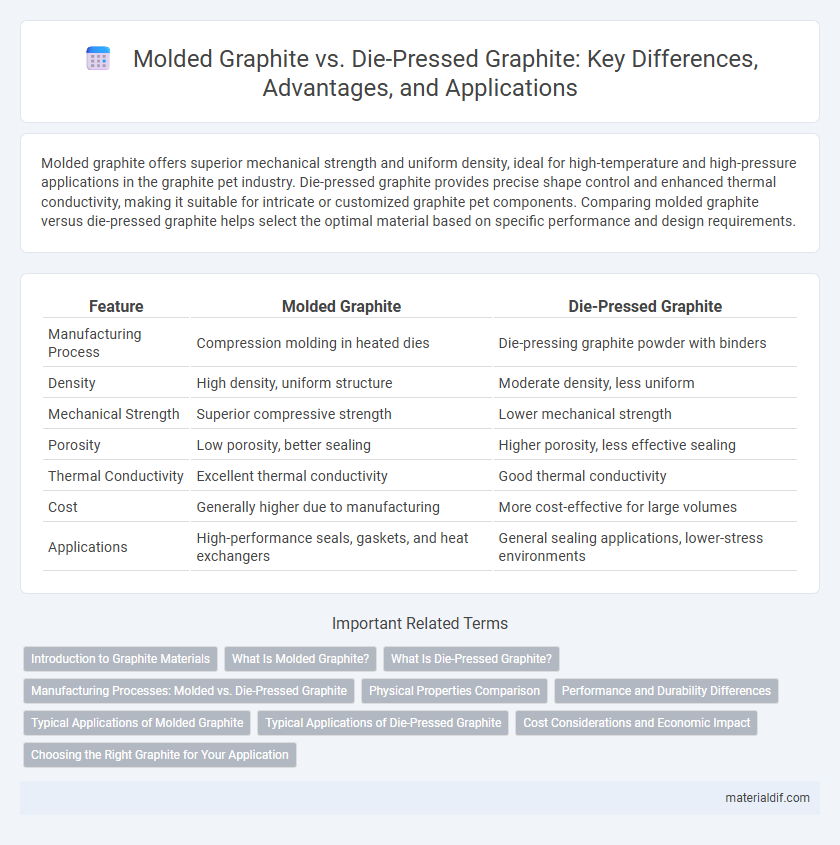

Table of Comparison

| Feature | Molded Graphite | Die-Pressed Graphite |

|---|---|---|

| Manufacturing Process | Compression molding in heated dies | Die-pressing graphite powder with binders |

| Density | High density, uniform structure | Moderate density, less uniform |

| Mechanical Strength | Superior compressive strength | Lower mechanical strength |

| Porosity | Low porosity, better sealing | Higher porosity, less effective sealing |

| Thermal Conductivity | Excellent thermal conductivity | Good thermal conductivity |

| Cost | Generally higher due to manufacturing | More cost-effective for large volumes |

| Applications | High-performance seals, gaskets, and heat exchangers | General sealing applications, lower-stress environments |

Introduction to Graphite Materials

Molded graphite is produced by compressing graphite powder with a binder under high pressure and temperature, resulting in a dense, durable material ideal for high-temperature applications. Die-pressed graphite involves pressing graphite powder into a die, allowing for precise shapes and sizes with excellent mechanical strength and thermal conductivity. Both materials offer unique properties for industrial use, with molded graphite emphasizing toughness and die-pressed graphite providing superior dimensional accuracy.

What Is Molded Graphite?

Molded graphite is a form of synthetic graphite produced by compressing graphite powder mixed with a binder into complex shapes using high-temperature molding processes. It exhibits excellent dimensional stability, high thermal conductivity, and resistance to chemical corrosion, making it ideal for gasket and seal applications in extreme environments. Compared to die-pressed graphite, molded graphite offers superior mechanical strength and versatility in creating intricate geometries.

What Is Die-Pressed Graphite?

Die-pressed graphite is a type of synthetic graphite produced by compressing fine graphite powders into a dense, uniform shape using high pressure in a die mold. This manufacturing process results in a material with excellent mechanical strength, high thermal conductivity, and precise dimensional control, making it suitable for industrial applications such as seals, gaskets, and heat exchangers. Die-pressed graphite typically exhibits lower porosity and higher purity compared to molded graphite, enhancing its performance in demanding environments.

Manufacturing Processes: Molded vs. Die-Pressed Graphite

Molded graphite is produced by mixing fine graphite particles with a binder, then compression molding into complex shapes under controlled heat and pressure, allowing intricate geometries and high strength. Die-pressed graphite involves filling a die cavity with graphite powder followed by uniaxial pressing, resulting in components with uniform density and excellent mechanical properties but limited shape complexity. The choice between molded and die-pressed graphite depends on production volume, dimensional accuracy, and design complexity requirements.

Physical Properties Comparison

Molded graphite exhibits higher density and superior mechanical strength compared to die-pressed graphite, making it ideal for applications requiring enhanced durability and resistance to thermal shock. Die-pressed graphite, while generally less dense, offers better isotropic properties with more uniform electrical and thermal conductivity. Both types vary in porosity, with molded graphite typically having lower porosity, resulting in improved corrosion resistance and structural integrity.

Performance and Durability Differences

Molded graphite exhibits higher density and uniformity compared to die-pressed graphite, resulting in superior thermal conductivity and mechanical strength. Die-pressed graphite typically shows more porosity, which can reduce its resistance to chemical corrosion and mechanical wear. Molded graphite's enhanced structural integrity ensures longer durability in high-temperature and high-stress environments, making it preferable for demanding industrial applications.

Typical Applications of Molded Graphite

Molded graphite is commonly used in applications requiring complex shapes and high-temperature resistance, such as heat exchangers, battery electrodes, and seals in aerospace and chemical industries. Its superior mechanical strength and dimensional stability make it ideal for components exposed to thermal cycling and corrosive environments. These typical applications benefit from molded graphite's ability to maintain performance under extreme conditions compared to die-pressed graphite.

Typical Applications of Die-Pressed Graphite

Die-pressed graphite is commonly used in applications requiring high strength and precision, such as seals, gaskets, and mechanical packing in chemical processing and power generation industries. Its dense, uniform structure provides excellent resistance to thermal shock, corrosion, and mechanical stress, making it ideal for demanding environments with fluctuating temperatures and aggressive chemicals. Key sectors benefiting from die-pressed graphite include petrochemical plants, steel manufacturing, and automotive exhaust systems.

Cost Considerations and Economic Impact

Molded graphite typically involves higher initial production costs due to complex shaping and tooling requirements, whereas die-pressed graphite offers a cost-effective alternative with faster manufacturing cycles and reduced waste. The economic impact of choosing molded graphite lies in its superior performance and durability, potentially lowering long-term maintenance and replacement expenses despite the upfront investment. Die-pressed graphite suits high-volume applications where minimizing unit cost is critical, enabling manufacturers to achieve economies of scale and improve overall cost efficiency.

Choosing the Right Graphite for Your Application

Molded graphite offers superior mechanical strength and isotropic properties, making it ideal for applications requiring uniform thermal conductivity and high durability. Die-pressed graphite, with its anisotropic structure, provides enhanced thermal shock resistance and is cost-effective for complex shapes with intricate designs. Selecting between molded and die-pressed graphite depends on application-specific requirements such as thermal conductivity, mechanical strength, and manufacturing complexity.

Molded Graphite vs Die-Pressed Graphite Infographic

materialdif.com

materialdif.com