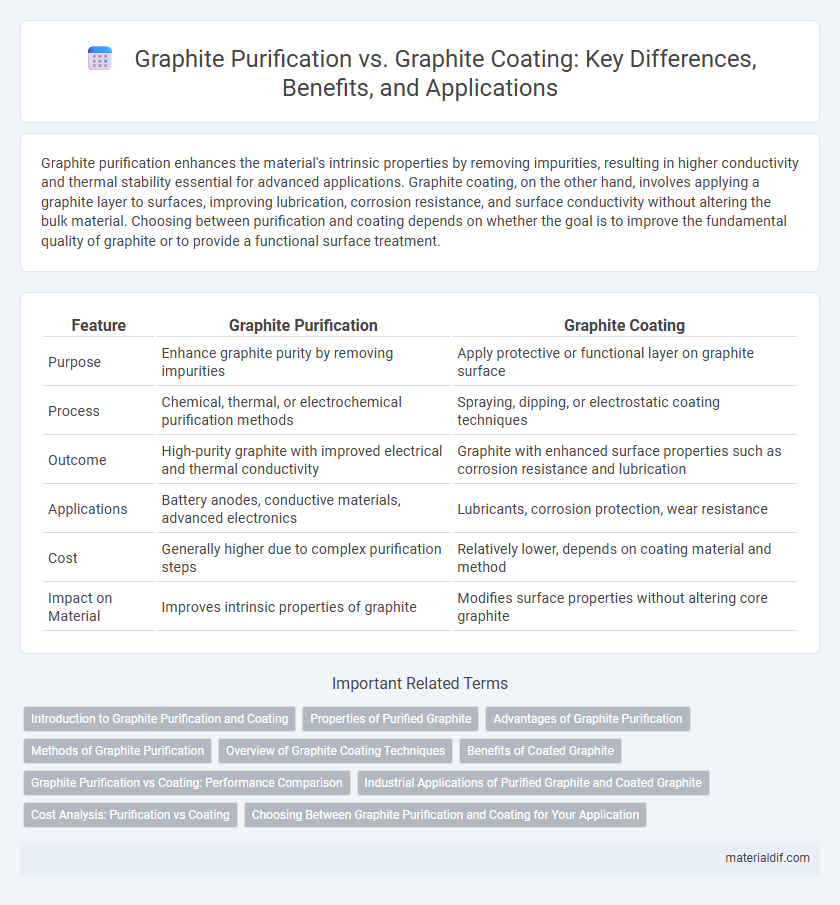

Graphite purification enhances the material's intrinsic properties by removing impurities, resulting in higher conductivity and thermal stability essential for advanced applications. Graphite coating, on the other hand, involves applying a graphite layer to surfaces, improving lubrication, corrosion resistance, and surface conductivity without altering the bulk material. Choosing between purification and coating depends on whether the goal is to improve the fundamental quality of graphite or to provide a functional surface treatment.

Table of Comparison

| Feature | Graphite Purification | Graphite Coating |

|---|---|---|

| Purpose | Enhance graphite purity by removing impurities | Apply protective or functional layer on graphite surface |

| Process | Chemical, thermal, or electrochemical purification methods | Spraying, dipping, or electrostatic coating techniques |

| Outcome | High-purity graphite with improved electrical and thermal conductivity | Graphite with enhanced surface properties such as corrosion resistance and lubrication |

| Applications | Battery anodes, conductive materials, advanced electronics | Lubricants, corrosion protection, wear resistance |

| Cost | Generally higher due to complex purification steps | Relatively lower, depends on coating material and method |

| Impact on Material | Improves intrinsic properties of graphite | Modifies surface properties without altering core graphite |

Introduction to Graphite Purification and Coating

Graphite purification involves the removal of impurities such as ash, silica, and metallic contaminants to enhance the material's conductivity and thermal stability, crucial for high-performance applications. Graphite coating, on the other hand, applies a thin layer of purified graphite onto surfaces to improve lubrication, corrosion resistance, and electrical conductivity. Both processes optimize graphite's functional properties, with purification focusing on material quality improvement and coating targeting surface enhancement.

Properties of Purified Graphite

Purified graphite exhibits enhanced electrical conductivity and thermal stability compared to coated graphite, making it ideal for high-performance applications such as batteries and fuel cells. The purification process removes impurities that otherwise degrade graphite's mechanical strength and corrosion resistance. This results in a material with superior structural integrity and consistent performance under extreme conditions.

Advantages of Graphite Purification

Graphite purification enhances the material's electrical conductivity and thermal stability by removing impurities such as ash, metals, and non-carbon elements, resulting in higher performance for battery and electronic applications. Purified graphite offers improved structural integrity and chemical resistance, leading to longer lifespan and reliability in high-demand industrial processes. This process also increases the graphite's purity level, which is critical for applications requiring ultra-high purity materials, outperforming coated graphite in consistency and performance.

Methods of Graphite Purification

Graphite purification primarily involves chemical methods such as acid leaching, thermal treatment, and flotation to remove impurities like silica, iron, and alumina, enhancing graphite's purity for industrial applications. Thermal purification uses high-temperature oxidation to oxidize non-graphitic carbon and impurities, achieving purity levels above 99.9%. Chemical leaching employs acids like hydrofluoric, hydrochloric, or sulfuric acid to dissolve metallic and non-metallic contaminants without damaging the graphite's crystalline structure.

Overview of Graphite Coating Techniques

Graphite coating techniques include chemical vapor deposition (CVD), electrophoretic deposition, and thermal spraying, each offering unique advantages in enhancing surface properties like conductivity, wear resistance, and corrosion protection. CVD produces high-purity, uniform graphite layers by decomposing hydrocarbon gases at elevated temperatures, while electrophoretic deposition allows controlled thickness on complex geometries through electric field-driven deposition of graphite particles. Thermal spraying applies molten graphite particles onto substrates, enabling rapid coating formation suitable for large-scale industrial applications.

Benefits of Coated Graphite

Coated graphite offers enhanced corrosion resistance and improved lubricity compared to purified graphite, making it ideal for high-performance industrial applications. The coating protects the graphite surface from oxidation and moisture damage, extending the material's lifespan and maintaining conductivity. These benefits enable coated graphite to perform reliably in harsh environments where pure graphite might degrade.

Graphite Purification vs Coating: Performance Comparison

Graphite purification enhances material purity by removing impurities such as ash and metallic contaminants, leading to improved electrical conductivity and thermal stability crucial for high-performance applications. In contrast, graphite coating provides a protective and lubricative surface layer that reduces friction and corrosion but does not improve the intrinsic purity or conductivity of the bulk material. Performance comparison reveals that purified graphite is superior for applications demanding high electrical and thermal efficiency, while coated graphite excels in environments requiring surface protection and wear resistance.

Industrial Applications of Purified Graphite and Coated Graphite

Purified graphite is essential in industrial applications such as lithium-ion batteries, nuclear reactors, and lubricants due to its enhanced electrical conductivity, thermal stability, and chemical inertness. Graphite coating improves surface properties including corrosion resistance, wear resistance, and hydrophobicity, making it ideal for aerospace, automotive, and electronic components. Both purified and coated graphite contribute significantly to performance optimization, durability, and efficiency in high-demand industrial environments.

Cost Analysis: Purification vs Coating

Graphite purification involves removing impurities to achieve high-purity graphite, which requires advanced chemical processes and specialized equipment, resulting in higher operational costs compared to graphite coating. Graphite coating, typically applied as a thin layer to enhance surface properties, involves less complex procedures and lower material consumption, leading to more cost-effective application for mass production. While purification is essential for high-performance applications demanding ultra-pure graphite, coating offers a budget-friendly solution for improving graphite functionality without extensive processing expenses.

Choosing Between Graphite Purification and Coating for Your Application

Choosing between graphite purification and coating depends on the specific application requirements, such as desired conductivity, thermal stability, and mechanical strength. Graphite purification enhances purity by removing impurities to improve electrical and thermal performance, while graphite coating provides a protective layer to prevent oxidation and corrosion. Evaluating factors like operating environment, performance goals, and cost-effectiveness guides the optimal solution selection for your graphite application.

Graphite Purification vs Graphite Coating Infographic

materialdif.com

materialdif.com