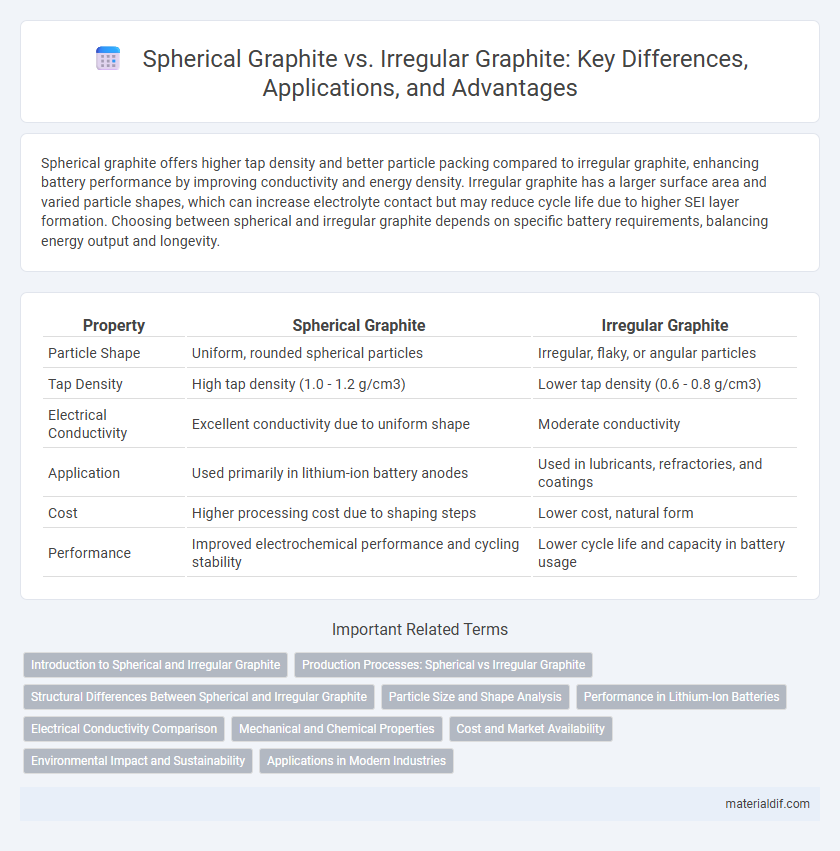

Spherical graphite offers higher tap density and better particle packing compared to irregular graphite, enhancing battery performance by improving conductivity and energy density. Irregular graphite has a larger surface area and varied particle shapes, which can increase electrolyte contact but may reduce cycle life due to higher SEI layer formation. Choosing between spherical and irregular graphite depends on specific battery requirements, balancing energy output and longevity.

Table of Comparison

| Property | Spherical Graphite | Irregular Graphite |

|---|---|---|

| Particle Shape | Uniform, rounded spherical particles | Irregular, flaky, or angular particles |

| Tap Density | High tap density (1.0 - 1.2 g/cm3) | Lower tap density (0.6 - 0.8 g/cm3) |

| Electrical Conductivity | Excellent conductivity due to uniform shape | Moderate conductivity |

| Application | Used primarily in lithium-ion battery anodes | Used in lubricants, refractories, and coatings |

| Cost | Higher processing cost due to shaping steps | Lower cost, natural form |

| Performance | Improved electrochemical performance and cycling stability | Lower cycle life and capacity in battery usage |

Introduction to Spherical and Irregular Graphite

Spherical graphite features a uniform, rounded morphology that offers excellent packing density and high electrical conductivity, making it ideal for lithium-ion battery anodes. Irregular graphite, characterized by uneven shapes and varied particle sizes, provides enhanced surface area and increased active sites for electrochemical reactions. Both types derive from natural or synthetic sources, with processing methods tailored to optimize their physical and electrochemical properties for specific industrial applications.

Production Processes: Spherical vs Irregular Graphite

Spherical graphite is produced through a rigorous process involving purification, micronization, and spheroidization to achieve uniform particle size and shape, essential for high-performance battery anodes. Irregular graphite, on the other hand, is typically sourced directly from natural flake graphite with minimal processing, resulting in variable particle morphology. The advanced production process of spherical graphite enhances conductivity and capacity in lithium-ion batteries, whereas irregular graphite serves applications requiring less stringent material consistency.

Structural Differences Between Spherical and Irregular Graphite

Spherical graphite exhibits a uniform, rounded morphology with high crystallinity, resulting in enhanced electrical conductivity and packing density compared to irregular graphite. Irregular graphite features a flaky, uneven structure with varying particle sizes and lower crystallinity, often leading to less efficient electrochemical performance. These structural differences critically impact their application in lithium-ion battery anodes, where spherical graphite promotes improved cycle stability and rate capability.

Particle Size and Shape Analysis

Spherical graphite exhibits a uniform particle size distribution with a smooth, round shape that enhances packing density and electrical conductivity in battery anodes. In contrast, irregular graphite features varied particle sizes and angular shapes, often leading to lower tap density and reduced electrochemical performance. Precise particle size and shape analysis using laser diffraction and scanning electron microscopy is essential to optimize graphite selection for lithium-ion battery applications.

Performance in Lithium-Ion Batteries

Spherical graphite exhibits higher packing density and superior conductivity compared to irregular graphite, leading to improved cycle life and rate performance in lithium-ion batteries. Its uniform particle size and shape enhance electrode manufacturing consistency and electrolyte penetration, optimizing charge-discharge efficiency. Irregular graphite, with varied particle morphology, often results in lower initial coulombic efficiency and reduced battery stability.

Electrical Conductivity Comparison

Spherical graphite exhibits higher electrical conductivity than irregular graphite due to its uniform particle size and well-defined crystalline structure, which facilitate efficient electron transfer. The rounded morphology of spherical graphite minimizes contact resistance and enhances packing density in electrodes, contributing to better conductive pathways. In contrast, irregular graphite's uneven shape and variable particle size lead to inconsistent electron flow and lower overall conductivity in battery applications.

Mechanical and Chemical Properties

Spherical graphite exhibits superior mechanical properties such as enhanced abrasion resistance and lower hardness compared to irregular graphite, making it ideal for battery anode applications. Chemically, spherical graphite demonstrates higher purity and better stability, ensuring improved electrochemical performance and longer lifecycle. Irregular graphite, with its flaky morphology, tends to have higher surface area but inferior structural integrity and chemical stability.

Cost and Market Availability

Spherical graphite generally commands a higher price due to its complex manufacturing process and superior performance in lithium-ion battery anodes, driving strong demand in the electric vehicle market. Irregular graphite, being more abundant and produced with simpler methods, remains significantly cheaper and widely available, primarily used in traditional applications like refractories and lubricants. Market availability for spherical graphite is constrained by limited processing capacity and geographic concentration, whereas irregular graphite benefits from extensive global reserves and steady supply chains.

Environmental Impact and Sustainability

Spherical graphite, used primarily in lithium-ion battery anodes, offers higher energy efficiency and reduces material waste compared to irregular graphite, which is less uniform and requires more intensive processing. The production of spherical graphite often demands higher energy consumption and chemical treatments, raising environmental concerns, but its improved performance contributes to longer battery life and less frequent replacements. Irregular graphite, sourced with less processing, may have a lower immediate carbon footprint, yet its reduced battery efficiency can lead to higher overall environmental impact over time.

Applications in Modern Industries

Spherical graphite offers superior conductivity and consistent particle size, making it ideal for use in lithium-ion battery anodes and advanced electronics. Irregular graphite, with its larger surface area and cost-effectiveness, is commonly utilized in steelmaking, refractory materials, and lubricants. Modern industries prioritize spherical graphite for energy storage innovations, while irregular graphite supports traditional manufacturing processes.

Spherical Graphite vs Irregular Graphite Infographic

materialdif.com

materialdif.com