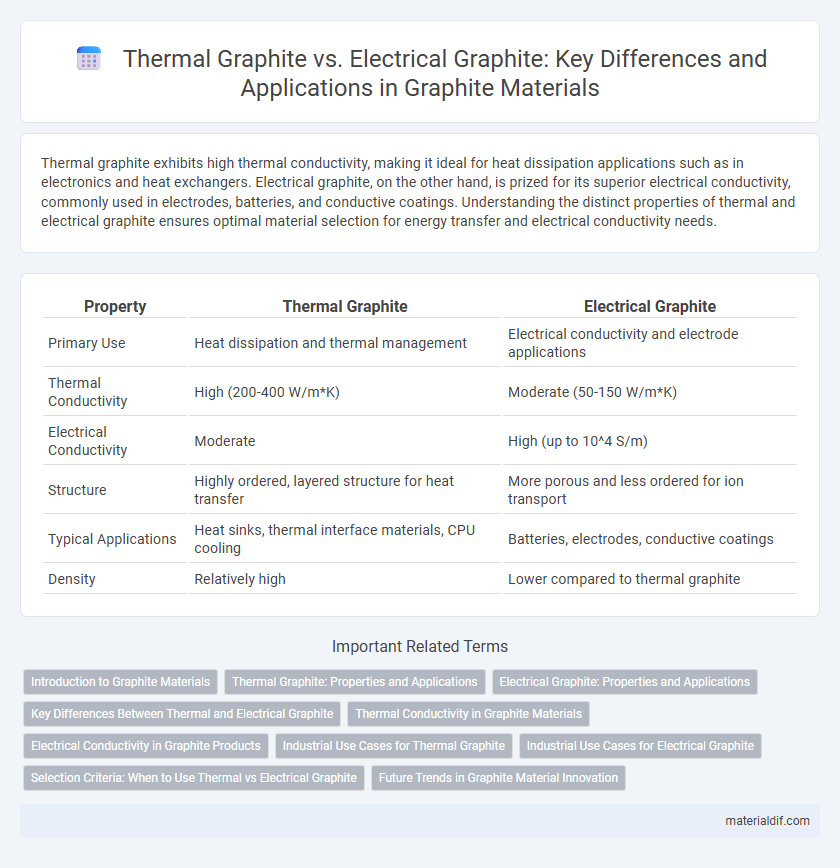

Thermal graphite exhibits high thermal conductivity, making it ideal for heat dissipation applications such as in electronics and heat exchangers. Electrical graphite, on the other hand, is prized for its superior electrical conductivity, commonly used in electrodes, batteries, and conductive coatings. Understanding the distinct properties of thermal and electrical graphite ensures optimal material selection for energy transfer and electrical conductivity needs.

Table of Comparison

| Property | Thermal Graphite | Electrical Graphite |

|---|---|---|

| Primary Use | Heat dissipation and thermal management | Electrical conductivity and electrode applications |

| Thermal Conductivity | High (200-400 W/m*K) | Moderate (50-150 W/m*K) |

| Electrical Conductivity | Moderate | High (up to 10^4 S/m) |

| Structure | Highly ordered, layered structure for heat transfer | More porous and less ordered for ion transport |

| Typical Applications | Heat sinks, thermal interface materials, CPU cooling | Batteries, electrodes, conductive coatings |

| Density | Relatively high | Lower compared to thermal graphite |

Introduction to Graphite Materials

Thermal graphite exhibits high thermal conductivity, making it ideal for heat dissipation in electronics and industrial applications. Electrical graphite features excellent electrical conductivity, commonly used in electrodes, batteries, and conductive coatings. Both forms share a layered crystal structure but differ primarily in purity, grain orientation, and additive content affecting their specific performance characteristics.

Thermal Graphite: Properties and Applications

Thermal graphite exhibits high thermal conductivity, low thermal expansion, and excellent heat resistance, making it ideal for heat exchangers, thermal management systems, and high-temperature industrial processes. Its anisotropic structure allows efficient heat dissipation, enhancing performance in electronic devices and aerospace components. Applications leverage thermal graphite's ability to withstand extreme temperatures while maintaining structural integrity and thermal stability.

Electrical Graphite: Properties and Applications

Electrical graphite exhibits high electrical conductivity, excellent thermal stability, and remarkable resistance to chemical corrosion, making it ideal for use in electrodes, batteries, and electrical contacts. Its crystalline structure allows efficient electron mobility, which is essential in applications like electric arc furnaces, lithium-ion batteries, and fuel cells. The material's durability under high temperatures and harsh environments ensures reliable performance in power generation and electronic device manufacturing.

Key Differences Between Thermal and Electrical Graphite

Thermal graphite exhibits high thermal conductivity, making it ideal for heat dissipation applications, while electrical graphite is characterized by excellent electrical conductivity used in electrodes and batteries. The crystal structure of thermal graphite allows for efficient phonon transport, whereas electrical graphite's structure facilitates electron mobility. Key differences also include their typical uses: thermal graphite is prevalent in heat sinks and thermal interface materials, and electrical graphite is essential in electrochemical cells and electrical contacts.

Thermal Conductivity in Graphite Materials

Thermal graphite exhibits exceptionally high thermal conductivity, typically ranging from 150 to 500 W/m*K, due to its highly ordered crystalline structure that facilitates efficient phonon transport. Electrical graphite, while also conductive, has comparatively lower thermal conductivity because its structure contains more defects and impurities that scatter heat-carrying phonons. Optimizing graphite materials for thermal management applications requires prioritizing thermal graphite variants to maximize heat dissipation efficiency.

Electrical Conductivity in Graphite Products

Electrical graphite exhibits superior electrical conductivity compared to thermal graphite due to its highly crystalline structure and lower impurity levels, making it ideal for applications requiring efficient electron flow. The anisotropic conductivity of graphite allows electrical graphite products to achieve conductivity values up to 10^4 S/m along the basal planes, significantly outperforming thermal graphite focused primarily on heat dissipation. Optimizing electrical conductivity in graphite products involves enhancing crystallinity and minimizing defects, crucial for industries such as electronics, batteries, and conductive coatings.

Industrial Use Cases for Thermal Graphite

Thermal graphite, characterized by its high thermal conductivity and stability at elevated temperatures, is extensively used in heat exchangers, thermal management systems, and refractory linings in industries such as aerospace, metallurgy, and electronics manufacturing. Its ability to withstand extreme thermal cycles without degradation makes it ideal for applications requiring efficient heat dissipation and insulation. Unlike electrical graphite, which prioritizes electrical conductivity for electrodes and batteries, thermal graphite's primary industrial use revolves around optimized heat transfer and thermal protection solutions.

Industrial Use Cases for Electrical Graphite

Electrical graphite, known for its high electrical conductivity and stability at elevated temperatures, is widely used in industrial applications such as electrodes for electric arc furnaces in steelmaking, battery anodes in lithium-ion cells, and conductive components in fuel cells. Its ability to maintain performance in harsh chemical environments makes it essential for electrochemical processes and semiconductor manufacturing. Thermal graphite, while excellent for heat dissipation, lacks the electrical conductivity required for these critical industrial uses.

Selection Criteria: When to Use Thermal vs Electrical Graphite

Thermal graphite is selected for applications requiring high thermal conductivity, such as heat sinks, thermal management in electronics, and heat exchangers, due to its ability to efficiently transfer heat. Electrical graphite, characterized by high electrical conductivity, is preferable in electrodes, batteries, and electrical contacts where efficient current flow is critical. Selection between thermal and electrical graphite depends primarily on whether the application demands superior heat dissipation or electrical conduction properties.

Future Trends in Graphite Material Innovation

Thermal graphite is engineered for superior heat conductivity, primarily utilized in electronics cooling and thermal management systems, while electrical graphite excels in conductivity and is essential in battery anodes and electric vehicle energy storage. Future trends in graphite material innovation emphasize enhancing purity and structural control to boost performance in next-generation lithium-ion batteries and flexible electronics. Advancements in synthetic graphite production and graphene integration are poised to revolutionize applications across energy storage, thermal management, and semiconductor industries.

Thermal Graphite vs Electrical Graphite Infographic

materialdif.com

materialdif.com