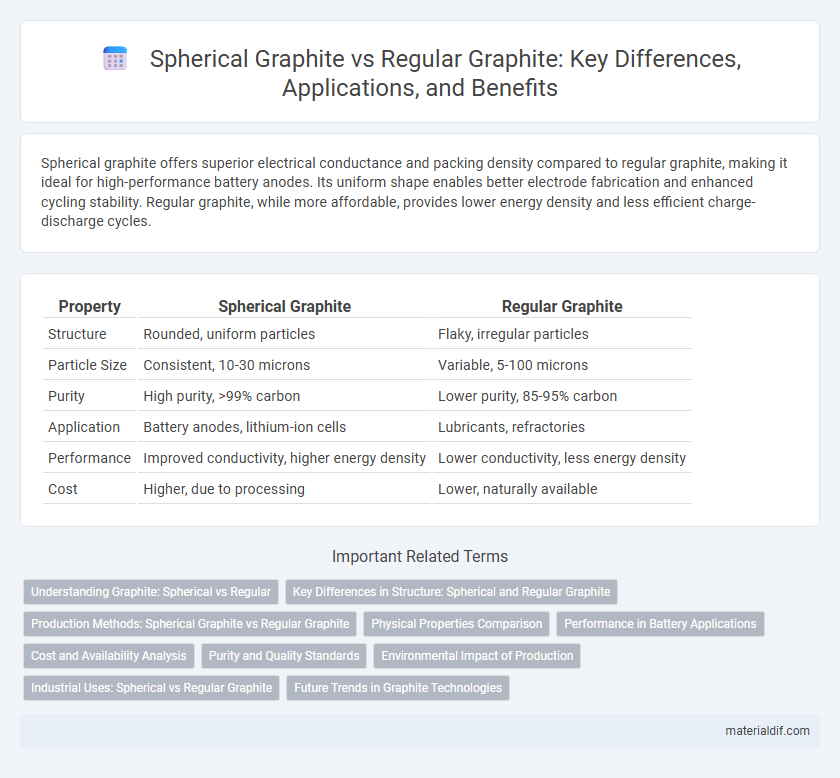

Spherical graphite offers superior electrical conductance and packing density compared to regular graphite, making it ideal for high-performance battery anodes. Its uniform shape enables better electrode fabrication and enhanced cycling stability. Regular graphite, while more affordable, provides lower energy density and less efficient charge-discharge cycles.

Table of Comparison

| Property | Spherical Graphite | Regular Graphite |

|---|---|---|

| Structure | Rounded, uniform particles | Flaky, irregular particles |

| Particle Size | Consistent, 10-30 microns | Variable, 5-100 microns |

| Purity | High purity, >99% carbon | Lower purity, 85-95% carbon |

| Application | Battery anodes, lithium-ion cells | Lubricants, refractories |

| Performance | Improved conductivity, higher energy density | Lower conductivity, less energy density |

| Cost | Higher, due to processing | Lower, naturally available |

Understanding Graphite: Spherical vs Regular

Spherical graphite features a unique, rounded particle shape that enhances packing density and manufacturing efficiency in lithium-ion battery anodes compared to regular flake graphite, which has a flat and irregular structure. Its superior uniformity improves electrode performance by offering better cyclability and rate capability, essential for high-performance energy storage. Regular graphite remains widely used for its natural abundance and cost-effectiveness but often requires additional processing to match the electrochemical properties of spherical graphite.

Key Differences in Structure: Spherical and Regular Graphite

Spherical graphite features a rounded, nearly perfect spherical particle shape, enhancing its packing density and conductivity, while regular graphite commonly exhibits flaky, plate-like structures with irregular shapes. The crystalline structure in spherical graphite is more uniform and compact, resulting in superior electrochemical performance, particularly in lithium-ion battery anodes. Regular graphite typically has a higher degree of crystallinity but lower surface area due to its planar morphology, affecting its reactivity and capacity retention.

Production Methods: Spherical Graphite vs Regular Graphite

Spherical graphite is produced through a milling and spheronization process that transforms flake graphite into uniform, spherical particles, enhancing its packing density and electrochemical properties. Regular graphite, typically mined as flake or amorphous graphite, undergoes minimal processing such as flotation and drying, preserving its natural flake structure without shape modification. The advanced production techniques for spherical graphite increase its suitability for lithium-ion battery anodes, contrasting with the simpler extraction methods used for regular graphite in industrial applications.

Physical Properties Comparison

Spherical graphite exhibits a uniform, rounded particle shape that enhances its tap density and packing efficiency compared to regular flake or amorphous graphite. Its higher purity and improved electrical conductivity stem from fewer structural defects and a more ordered crystalline structure. These physical properties make spherical graphite ideal for high-performance applications such as lithium-ion battery anodes, where consistent particle size and morphology are critical.

Performance in Battery Applications

Spherical graphite offers higher tap density and improved packing efficiency compared to regular flake graphite, leading to enhanced energy storage capacity and longer battery life in lithium-ion applications. Its uniform particle size and shape facilitate better electrode fabrication, resulting in superior charge-discharge rates and cycle stability. Regular graphite, while more abundant and cost-effective, typically exhibits lower electrochemical performance due to irregular particle morphology and reduced conductivity.

Cost and Availability Analysis

Spherical graphite generally costs more than regular graphite due to its intricate manufacturing process, which involves milling and shaping to achieve uniform particle size and spherical morphology. Availability of spherical graphite is more limited compared to natural flake or amorphous regular graphite, as it is often produced through synthetic or highly processed methods. The scarcity and higher production expenses of spherical graphite make it less accessible but preferred for high-performance applications like lithium-ion battery anodes.

Purity and Quality Standards

Spherical graphite demonstrates higher purity levels compared to regular graphite, often exceeding 99.5% carbon content, which is critical for battery-grade applications. Its uniform particle size and shape enhance quality standards by ensuring better conductivity and electrochemical performance. These attributes make spherical graphite essential for high-performance lithium-ion batteries and advanced industrial uses.

Environmental Impact of Production

Spherical graphite production generates higher environmental impacts due to energy-intensive processes like milling and purification, resulting in greater carbon emissions compared to regular graphite mining and processing. Regular graphite extraction typically involves open-pit or underground mining with lower energy consumption but can cause ecosystem disruption and water contamination if not managed properly. Advances in sustainable production methods and recycling technologies are essential to reduce the carbon footprint and ecological damage associated with both spherical and regular graphite manufacturing.

Industrial Uses: Spherical vs Regular Graphite

Spherical graphite, characterized by its uniform particle size and high purity, is predominantly used in lithium-ion battery anodes due to its superior electrochemical performance and consistent charge-discharge cycles. Regular graphite, with irregular flaky particles and lower purity, serves well in steelmaking, refractory materials, and lubricants where structural integrity and thermal resistance are critical. The industrial preference for spherical graphite in energy storage contrasts with regular graphite's broad utility in traditional manufacturing and metallurgical processes.

Future Trends in Graphite Technologies

Spherical graphite is gaining prominence over regular graphite due to its enhanced electrochemical properties, making it a preferred material in lithium-ion battery anodes, which are critical for electric vehicle and renewable energy storage advancements. Future trends in graphite technologies highlight increased investments in scalable production of spherical graphite with improved purity and particle size uniformity, driving efficiency and capacity improvements in energy storage applications. Innovations in sustainable and eco-friendly processing methods for spherical graphite are expected to reduce environmental impact while meeting growing global demand.

Spherical Graphite vs Regular Graphite Infographic

materialdif.com

materialdif.com