Graphite powder offers finer granularity and is ideal for applications requiring high surface area and rapid thermal conductivity, such as lubricants and batteries. Graphite blocks provide enhanced structural strength and durability, making them suitable for machining, electrodes, and high-temperature furnace components. Choosing between graphite powder and blocks depends on the specific industrial need for flexibility versus mechanical stability.

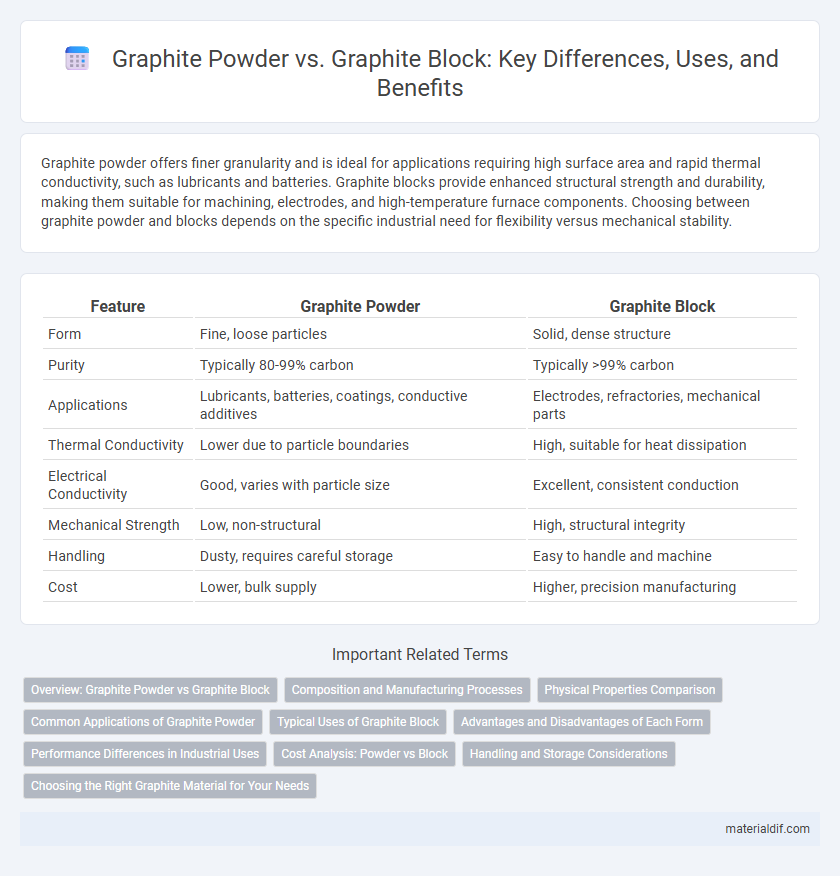

Table of Comparison

| Feature | Graphite Powder | Graphite Block |

|---|---|---|

| Form | Fine, loose particles | Solid, dense structure |

| Purity | Typically 80-99% carbon | Typically >99% carbon |

| Applications | Lubricants, batteries, coatings, conductive additives | Electrodes, refractories, mechanical parts |

| Thermal Conductivity | Lower due to particle boundaries | High, suitable for heat dissipation |

| Electrical Conductivity | Good, varies with particle size | Excellent, consistent conduction |

| Mechanical Strength | Low, non-structural | High, structural integrity |

| Handling | Dusty, requires careful storage | Easy to handle and machine |

| Cost | Lower, bulk supply | Higher, precision manufacturing |

Overview: Graphite Powder vs Graphite Block

Graphite powder consists of fine, loose particles with high surface area, making it ideal for applications requiring rapid heat dissipation or lubrication. Graphite blocks are solid, dense forms offering superior strength and durability, commonly used in manufacturing electrodes and molds for high-temperature processes. The choice between graphite powder and blocks depends on the specific industrial needs such as surface finish, thermal conductivity, and mechanical stability.

Composition and Manufacturing Processes

Graphite powder consists of finely ground graphite particles primarily produced through the mechanical milling or pulverization of natural or synthetic graphite, ensuring high purity and controlled particle size for applications requiring precise dispersion. Graphite blocks are manufactured through compression and sintering processes where graphite powder or flake is combined with binders, then subjected to high temperatures to create dense, solid structures with enhanced mechanical strength and thermal conductivity. The choice between powder and block forms depends on desired properties like particle size distribution for powders and structural integrity for blocks in industrial applications such as refractory materials and electrodes.

Physical Properties Comparison

Graphite powder consists of fine, loose particles with a high surface area, resulting in superior lubricity and faster reaction rates in chemical processes, while graphite blocks are dense, solid masses offering greater mechanical strength and structural stability for industrial applications. Powdered graphite exhibits lower bulk density and higher porosity compared to the compact, low-porosity graphite blocks, which have higher thermal conductivity and enhanced resistance to thermal shock. The crystalline structure remains consistent, but the physical form influences heat dissipation, electrical conductivity, and wear resistance, making each suitable for different engineering requirements.

Common Applications of Graphite Powder

Graphite powder is widely used in lubricants, batteries, and conductive coatings due to its high purity and fine particle size, enabling enhanced conductivity and smooth application. It is essential in refractory materials and brake linings where thermal stability and wear resistance are required. Unlike graphite blocks, which are favored for structural components in high-temperature environments, graphite powder excels in applications requiring dispersion and surface coverage.

Typical Uses of Graphite Block

Graphite blocks are commonly used in industrial applications such as electrodes for electric arc furnaces, heat exchangers, and molds for continuous casting due to their high density and structural integrity. Unlike graphite powder, which is ideal for lubricants and conductive coatings, graphite blocks provide superior thermal conductivity and mechanical strength in high-temperature environments. Their ability to withstand extreme thermal shock and chemical corrosion makes them essential in metallurgy, aerospace, and chemical processing industries.

Advantages and Disadvantages of Each Form

Graphite powder offers superior mixing capabilities and faster reaction rates due to its high surface area but can be messy and difficult to handle in precise applications. Graphite blocks provide structural stability and excellent thermal conductivity, making them ideal for high-temperature industrial uses, though they lack the reactivity and flexibility of powders. Choosing between graphite powder and blocks depends on the specific application requirements such as ease of handling, surface area needs, and thermal performance.

Performance Differences in Industrial Uses

Graphite powder offers superior surface area and reactivity, making it ideal for applications requiring rapid thermal conductivity and efficient lubrication in metal processing and battery anodes. In contrast, graphite blocks provide enhanced structural integrity and durability, suited for high-temperature environments such as furnace linings and electrolysis electrodes. The choice between powder and block hinges on the specific industrial performance requirements, balancing reactive efficiency against mechanical stability.

Cost Analysis: Powder vs Block

Graphite powder generally offers a lower upfront cost compared to graphite blocks, making it ideal for applications requiring high surface area and ease of mixing. Graphite blocks, while more expensive, provide superior durability and structural integrity for industrial uses such as electrodes and molds. Cost efficiency depends on the specific requirements of thermal conductivity, mechanical strength, and processing method.

Handling and Storage Considerations

Graphite powder requires careful handling to prevent dust inhalation and contamination, necessitating storage in tightly sealed, moisture-resistant containers to maintain quality. Graphite blocks, being solid and less prone to airborne particles, offer easier handling and reduce the risk of dispersion but still need protection from moisture and mechanical damage. Both forms benefit from storage in cool, dry environments to preserve their physical and chemical properties.

Choosing the Right Graphite Material for Your Needs

Graphite powder offers greater surface area and is ideal for applications requiring efficient lubrication, conductivity, or heat dissipation, while graphite blocks provide structural stability and are preferred in high-temperature, high-stress environments like molds and electrodes. The choice between powder and block largely depends on the specific thermal, mechanical, and electrical properties required for the task. Selecting the right graphite material ensures optimal performance, cost-effectiveness, and longevity in industrial or manufacturing processes.

Graphite Powder vs Graphite Block Infographic

materialdif.com

materialdif.com