Graphite pets exhibit a unique balance between porosity and impermeability, allowing them to retain moisture while preventing liquid penetration. The porous structure enhances gas exchange and thermal regulation, crucial for their function in casting processes. Impermeability ensures the integrity of the graphite pet against molten metals, maintaining its durability and performance.

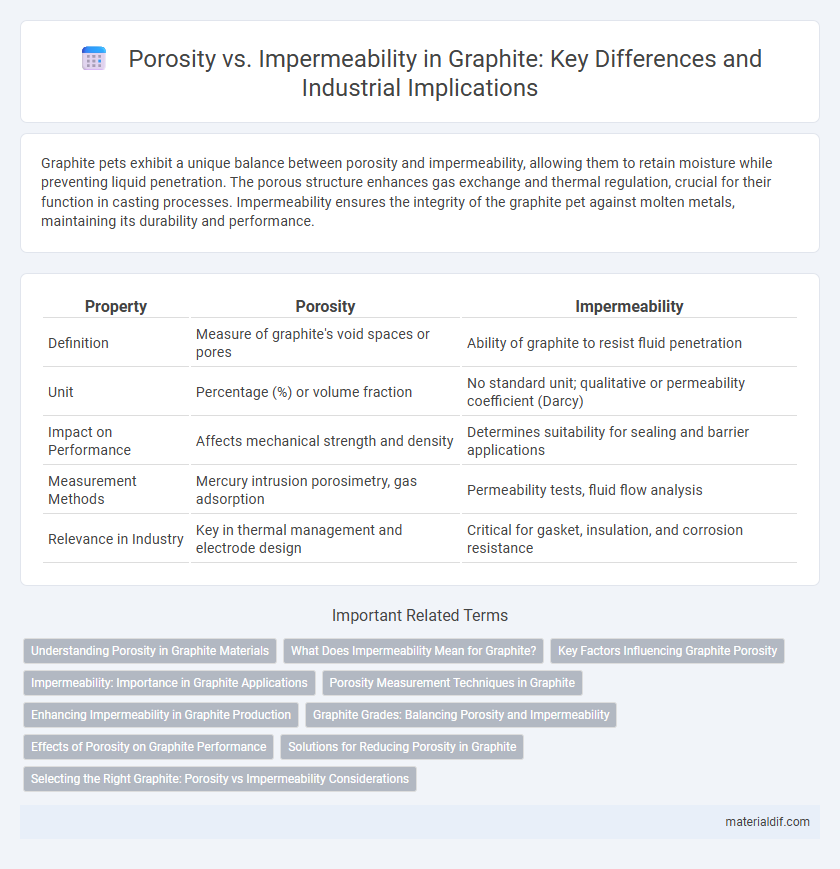

Table of Comparison

| Property | Porosity | Impermeability |

|---|---|---|

| Definition | Measure of graphite's void spaces or pores | Ability of graphite to resist fluid penetration |

| Unit | Percentage (%) or volume fraction | No standard unit; qualitative or permeability coefficient (Darcy) |

| Impact on Performance | Affects mechanical strength and density | Determines suitability for sealing and barrier applications |

| Measurement Methods | Mercury intrusion porosimetry, gas adsorption | Permeability tests, fluid flow analysis |

| Relevance in Industry | Key in thermal management and electrode design | Critical for gasket, insulation, and corrosion resistance |

Understanding Porosity in Graphite Materials

Porosity in graphite materials significantly influences their permeability and overall performance in industrial applications. High porosity in graphite enhances fluid absorption and diffusion but reduces impermeability, making the material suitable for filtration or insulation purposes. Understanding the balance between porosity and impermeability is crucial for optimizing graphite's functionality in aerospace, nuclear reactors, and battery anodes.

What Does Impermeability Mean for Graphite?

Impermeability in graphite refers to its ability to resist the passage of fluids and gases through its structure, which is crucial for applications requiring barrier properties. Despite graphite's inherent porosity due to its layered crystalline structure, its impermeability is enhanced by the compact arrangement of graphene layers and minimal pore connectivity. This makes graphite an ideal material for seals, electrodes, and protective coatings where preventing fluid infiltration is essential.

Key Factors Influencing Graphite Porosity

Graphite porosity is primarily influenced by factors such as raw material quality, production temperature, and the degree of graphitization, which affect the material's pore size and distribution. High temperatures during graphitization typically reduce porosity by enhancing crystal structure alignment, thereby increasing impermeability. Impurities and binder content also play critical roles, as they can create microvoids that compromise the material's overall impermeability.

Impermeability: Importance in Graphite Applications

Impermeability is a critical property of graphite that significantly influences its effectiveness in high-performance applications such as sealing, lubrication, and electrochemical cells. The low porosity of high-quality graphite enhances its impermeability, preventing the passage of gases and liquids, which is essential for maintaining the integrity and longevity of seals and battery electrodes. This impermeable characteristic ensures that graphite components resist chemical attack, reduce contamination risks, and deliver consistent performance in demanding industrial environments.

Porosity Measurement Techniques in Graphite

Porosity measurement in graphite employs techniques such as mercury intrusion porosimetry, gas adsorption, and helium pycnometry to accurately quantify pore volume and size distribution. These methods reveal critical insights into graphite's microstructure, directly influencing its permeability and overall impermeability. Understanding porosity through precise measurement techniques is essential for optimizing graphite's performance in applications requiring controlled fluid flow and barrier properties.

Enhancing Impermeability in Graphite Production

Enhancing impermeability in graphite production involves controlling porosity levels to minimize fluid penetration and improve structural integrity. Advanced processing techniques such as high-temperature sintering and chemical vapor infiltration reduce pore size and connectivity, resulting in a dense, impervious graphite matrix. Optimizing these parameters ensures superior performance in applications requiring resistance to corrosive environments and gas diffusion.

Graphite Grades: Balancing Porosity and Impermeability

Graphite grades vary significantly in porosity and impermeability, directly impacting their performance in industrial applications. High-purity, fine-grained graphite exhibits low porosity and superior impermeability, making it ideal for sealing and lubrication in extreme environments. Coarser, more porous graphite grades may sacrifice impermeability for enhanced thermal and electrical conductivity, necessitating careful selection based on specific operational demands.

Effects of Porosity on Graphite Performance

Higher porosity in graphite significantly reduces its impermeability, leading to increased gas and liquid permeability which can compromise structural integrity and decrease thermal conductivity. Porous graphite exhibits lower density and mechanical strength, adversely affecting its performance in high-pressure environments such as nuclear reactors and aerospace applications. Controlling porosity levels is crucial to optimizing graphite's durability, sealing capabilities, and thermal stability.

Solutions for Reducing Porosity in Graphite

Effective solutions for reducing porosity in graphite include high-temperature sintering and chemical vapor infiltration, which enhance density and minimize pore volume. Utilizing finely graded graphite powders and applying hot isostatic pressing (HIP) significantly improve impermeability by closing micro-voids and cracks. These methods collectively optimize the structural integrity and performance of graphite in applications demanding low porosity and high impermeability.

Selecting the Right Graphite: Porosity vs Impermeability Considerations

Selecting the right graphite requires balancing porosity and impermeability to meet specific industrial needs; high-porosity graphite offers excellent absorption and catalytic properties but may allow fluid penetration, while impermeable graphite provides superior resistance to chemical attack and fluid leakage, ideal for sealing and gasketing applications. The pore size distribution and total porosity directly influence mechanical strength and durability, with low-porosity graphite preferred for high-pressure and high-temperature environments. Evaluating the trade-off between porosity for reactivity and impermeability for protection ensures optimal performance in batteries, lubricants, and refractory materials.

Porosity vs Impermeability Infographic

materialdif.com

materialdif.com