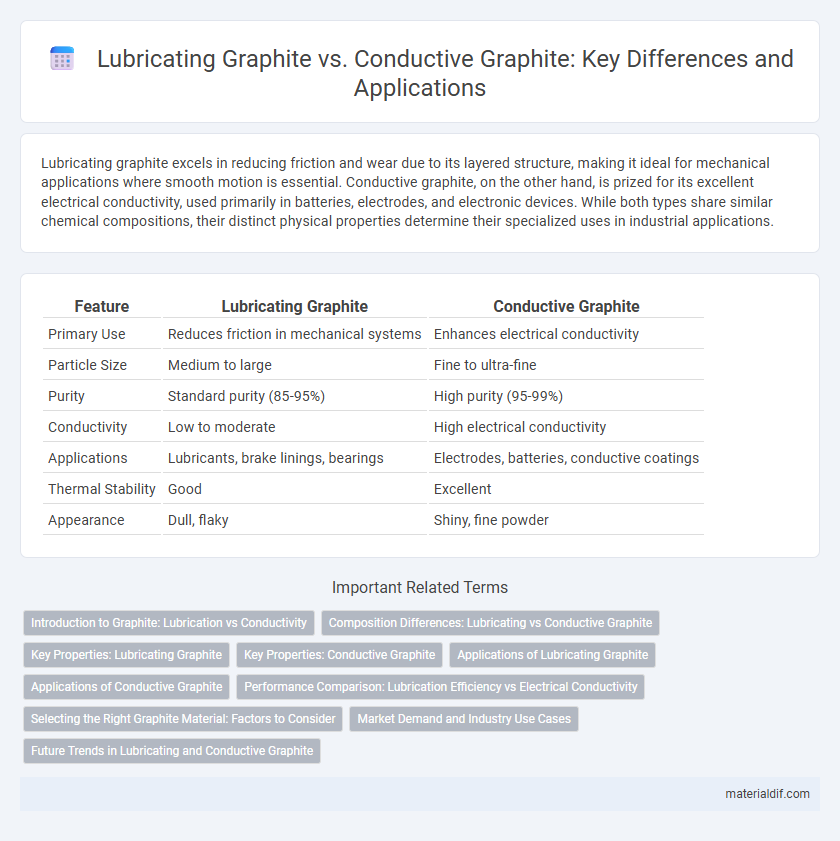

Lubricating graphite excels in reducing friction and wear due to its layered structure, making it ideal for mechanical applications where smooth motion is essential. Conductive graphite, on the other hand, is prized for its excellent electrical conductivity, used primarily in batteries, electrodes, and electronic devices. While both types share similar chemical compositions, their distinct physical properties determine their specialized uses in industrial applications.

Table of Comparison

| Feature | Lubricating Graphite | Conductive Graphite |

|---|---|---|

| Primary Use | Reduces friction in mechanical systems | Enhances electrical conductivity |

| Particle Size | Medium to large | Fine to ultra-fine |

| Purity | Standard purity (85-95%) | High purity (95-99%) |

| Conductivity | Low to moderate | High electrical conductivity |

| Applications | Lubricants, brake linings, bearings | Electrodes, batteries, conductive coatings |

| Thermal Stability | Good | Excellent |

| Appearance | Dull, flaky | Shiny, fine powder |

Introduction to Graphite: Lubrication vs Conductivity

Lubricating graphite possesses a layered crystalline structure that reduces friction and wear, making it ideal for industrial applications where smooth mechanical operation is essential. In contrast, conductive graphite features higher purity and electrical conductivity, utilized extensively in batteries, electrodes, and electronic devices. Understanding these distinctions is crucial for selecting the appropriate graphite type based on lubrication needs or electrical performance requirements.

Composition Differences: Lubricating vs Conductive Graphite

Lubricating graphite primarily consists of high-purity natural graphite flakes with a layered structure that reduces friction and wear, making it ideal for lubrication applications. Conductive graphite contains a higher proportion of synthetic graphite and often includes bonding agents or conductive additives to enhance electrical conductivity for use in electrodes and batteries. The key compositional difference lies in the purity and structural arrangement designed to optimize either lubricity or electrical performance.

Key Properties: Lubricating Graphite

Lubricating graphite is characterized by its excellent lubricity, low friction coefficient, and high thermal stability, making it ideal for applications requiring reduced wear and smooth mechanical movement. Its layered structure allows easy shear between carbon planes, providing effective solid lubrication even under extreme temperatures and pressures. This type of graphite often features high purity and fine particle size to maximize surface coverage and minimize contaminants that could impair lubrication performance.

Key Properties: Conductive Graphite

Conductive graphite exhibits high electrical conductivity due to its crystalline structure, making it essential in applications such as batteries, electrodes, and fuel cells. Its ability to maintain stable conductivity under extreme temperatures and chemical environments ensures reliable performance in electronic and industrial systems. The key properties include low electrical resistivity, excellent thermal stability, and strong mechanical strength, distinguishing it from lubricating graphite used primarily for reducing friction.

Applications of Lubricating Graphite

Lubricating graphite is primarily used in applications requiring high-temperature stability and excellent lubrication properties, such as in automotive brake linings, industrial machinery, and dry lubricants for heavy equipment. Its layered structure reduces friction and wear in moving parts, making it ideal for use in pumps, valves, and bearings where conventional oils and greases may fail. These applications leverage lubricating graphite's thermal resilience and chemical inertness to enhance equipment durability and operational efficiency.

Applications of Conductive Graphite

Conductive graphite is widely used in electronic applications such as batteries, fuel cells, and electromagnetic shielding due to its excellent electrical conductivity and chemical stability. It plays a crucial role in manufacturing electrodes for lithium-ion batteries and supercapacitors, enhancing energy storage efficiency. Moreover, conductive graphite is essential in creating conductive coatings and composites for flexible electronics and sensors.

Performance Comparison: Lubrication Efficiency vs Electrical Conductivity

Lubricating graphite excels in reducing friction and wear due to its layered crystal structure, making it ideal for high-performance mechanical applications requiring effective lubrication. Conductive graphite, characterized by its higher purity and fewer impurities, offers superior electrical conductivity essential for electrodes, batteries, and electronic devices. While lubricating graphite prioritizes lubrication efficiency, conductive graphite ensures maximum electrical performance, highlighting their distinct optimization in performance metrics.

Selecting the Right Graphite Material: Factors to Consider

Selecting the right graphite material requires evaluating its intended application, whether for lubrication or conductivity. Lubricating graphite excels in reducing friction and wear in mechanical systems, while conductive graphite is optimized for electrical and thermal conductivity in electronic components. Key factors include particle size, purity, crystallinity, and thermal stability, which directly impact performance efficiency and durability in specific industrial uses.

Market Demand and Industry Use Cases

Lubricating graphite commands significant market demand in automotive, aerospace, and manufacturing industries due to its superior friction-reducing properties and high thermal stability, essential for engine components and industrial machinery. Conductive graphite finds extensive use in electronics, energy storage, and battery applications, driven by its excellent electrical conductivity and corrosion resistance, supporting the growth of electric vehicles and renewable energy sectors. Rising industrial automation and sustainable energy initiatives further propel the demand for both types, with lubricating graphite optimizing mechanical performance while conductive graphite enhances electrical efficiency.

Future Trends in Lubricating and Conductive Graphite

Future trends in lubricating and conductive graphite emphasize enhanced purity and nano-engineering to improve performance in electric vehicles and renewable energy technologies. Advanced lubricating graphite formulations reduce friction and wear in high-precision machinery, while conductive graphite innovations focus on boosting electrical conductivity and thermal management in batteries and flexible electronics. Integration of sustainable production methods and graphene hybrids is anticipated to drive efficiency and environmental benefits across industries.

Lubricating Graphite vs Conductive Graphite Infographic

materialdif.com

materialdif.com