Expandable graphite offers superior heat resistance and fire-retardant properties compared to standard graphite, making it ideal for use in high-temperature industrial applications. Its unique ability to expand when exposed to heat enhances insulation and protection, whereas standard graphite primarily serves as a lubricant or conductor. Choosing expandable graphite over standard graphite improves safety and durability in demanding environments.

Table of Comparison

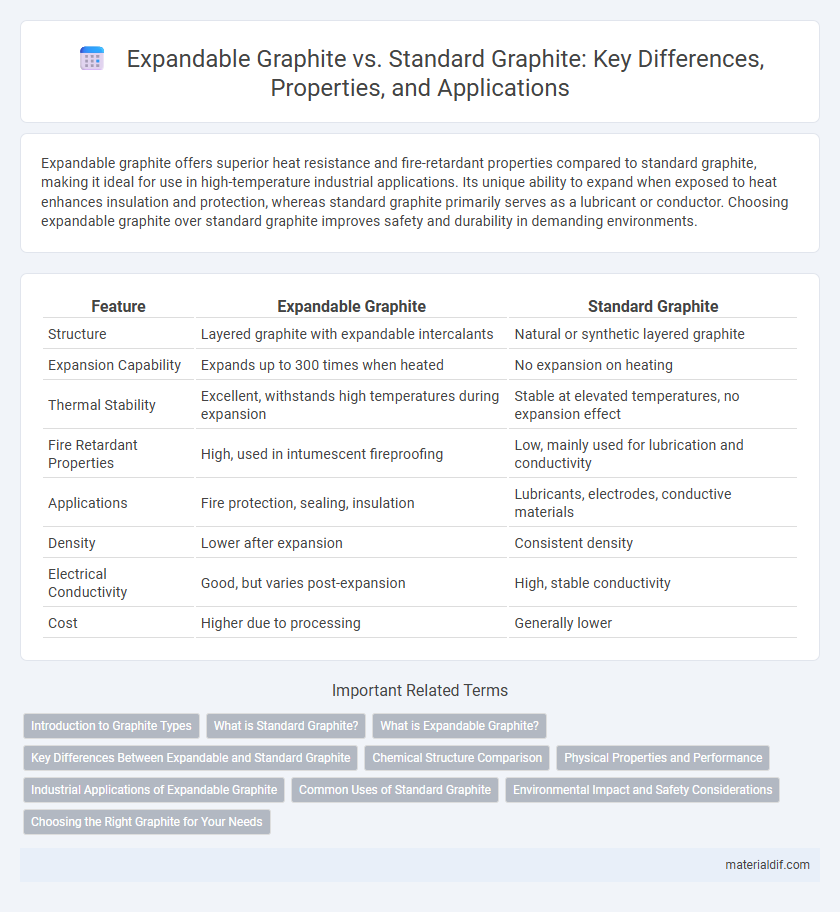

| Feature | Expandable Graphite | Standard Graphite |

|---|---|---|

| Structure | Layered graphite with expandable intercalants | Natural or synthetic layered graphite |

| Expansion Capability | Expands up to 300 times when heated | No expansion on heating |

| Thermal Stability | Excellent, withstands high temperatures during expansion | Stable at elevated temperatures, no expansion effect |

| Fire Retardant Properties | High, used in intumescent fireproofing | Low, mainly used for lubrication and conductivity |

| Applications | Fire protection, sealing, insulation | Lubricants, electrodes, conductive materials |

| Density | Lower after expansion | Consistent density |

| Electrical Conductivity | Good, but varies post-expansion | High, stable conductivity |

| Cost | Higher due to processing | Generally lower |

Introduction to Graphite Types

Expandable graphite is a modified form of standard graphite treated to rapidly expand when heated, resulting in a worm-like structure that enhances flame retardant properties. Standard graphite consists of naturally occurring crystalline carbon with excellent electrical conductivity and lubricity, commonly used in electrodes, batteries, and lubricants. Both types share a layered hexagonal structure but differ significantly in thermal expansion behavior and application-specific performance.

What is Standard Graphite?

Standard graphite is a naturally occurring form of carbon characterized by its layered, planar structure that allows easy cleavage into thin, flexible sheets. It exhibits excellent electrical and thermal conductivity, making it ideal for applications in batteries, lubricants, and refractories. Unlike expandable graphite, standard graphite does not undergo significant expansion when heated, retaining its original density and structural integrity.

What is Expandable Graphite?

Expandable graphite is a form of graphite treated with acids and heat to cause rapid expansion when exposed to high temperatures, resulting in a worm-like, lightweight material with excellent fire retardant properties. Unlike standard graphite, which is primarily used for lubrication and conductivity, expandable graphite enhances fire resistance by forming an insulating char layer that protects underlying materials from heat. This makes it ideal for applications in flame retardant composites, coatings, and gaskets.

Key Differences Between Expandable and Standard Graphite

Expandable graphite differs from standard graphite primarily in its ability to expand when heated, due to intercalated compounds within its layers, making it ideal for fire-resistant applications. Standard graphite consists of tightly packed layers with excellent electrical conductivity and thermal stability but lacks the expandable property. The structural differences result in varied uses, with expandable graphite often employed in flame retardants and sealing materials, while standard graphite is preferred for electrodes, lubricants, and batteries.

Chemical Structure Comparison

Expandable graphite consists of layered carbon atoms arranged in a hexagonal lattice with intercalated molecules, typically acids or oxidizers, that cause expansion upon heating. Standard graphite features a similar hexagonal lattice of carbon atoms but lacks intercalated compounds, resulting in a stable, non-expandable structure. The presence of intercalated species in expandable graphite significantly alters its chemical reactivity and physical properties compared to standard graphite.

Physical Properties and Performance

Expandable graphite exhibits a unique layered, crystalline structure that allows it to expand significantly when heated, enhancing its thermal insulation and fire-resistant properties compared to standard graphite. Standard graphite maintains high electrical and thermal conductivity along with excellent lubricity due to its dense, flaky morphology, making it ideal for mechanical applications. The expanded form provides superior volume increase and intumescent behavior, leading to improved sealing and cushioning performance in fire protection systems.

Industrial Applications of Expandable Graphite

Expandable graphite offers superior fire retardancy and thermal insulation compared to standard graphite, making it invaluable in industrial applications such as flame retardant additives in plastics, rubber, and coatings. Its ability to expand up to 300 times its original volume upon heating enhances protective barriers in battery manufacturing, automotive parts, and construction materials. These properties drive its widespread use in industries demanding high-performance safety and durability standards.

Common Uses of Standard Graphite

Standard graphite is widely used in applications such as lubricants, pencils, refractory materials, and batteries due to its excellent thermal conductivity and chemical stability. It serves crucial roles in steelmaking as a carbon additive and in brake linings for its frictional properties. Additionally, standard graphite is employed in electrochemical devices and as a moderator in nuclear reactors.

Environmental Impact and Safety Considerations

Expandable graphite produces fewer airborne particulates during handling compared to standard graphite, reducing respiratory hazards in industrial environments. Its exfoliation process lessens the need for hazardous chemicals, thereby minimizing soil and water contamination risks. Standard graphite mining and processing often involve higher energy consumption and greater environmental disruption, whereas expandable graphite offers a safer, more sustainable alternative with lower emissions and improved worker safety.

Choosing the Right Graphite for Your Needs

Expandable graphite offers superior thermal stability and enhanced exfoliation properties compared to standard graphite, making it ideal for fire-resistant and sealing applications. Standard graphite provides excellent electrical conductivity and lubrication benefits, preferred in battery electrodes and industrial lubricants. Selecting the right graphite depends on specific requirements such as heat resistance, mechanical flexibility, and electrical performance to ensure optimal functionality and durability.

Expandable Graphite vs Standard Graphite Infographic

materialdif.com

materialdif.com