Isostatic graphite offers uniform density and isotropic properties, making it ideal for complex shapes and applications requiring consistent strength in all directions. Extruded graphite provides directional strength with higher thermal conductivity along the extrusion axis, suitable for simpler geometries and heat dissipation needs. Selecting between isostatic and extruded graphite depends on the specific mechanical and thermal requirements of the graphite pet.

Table of Comparison

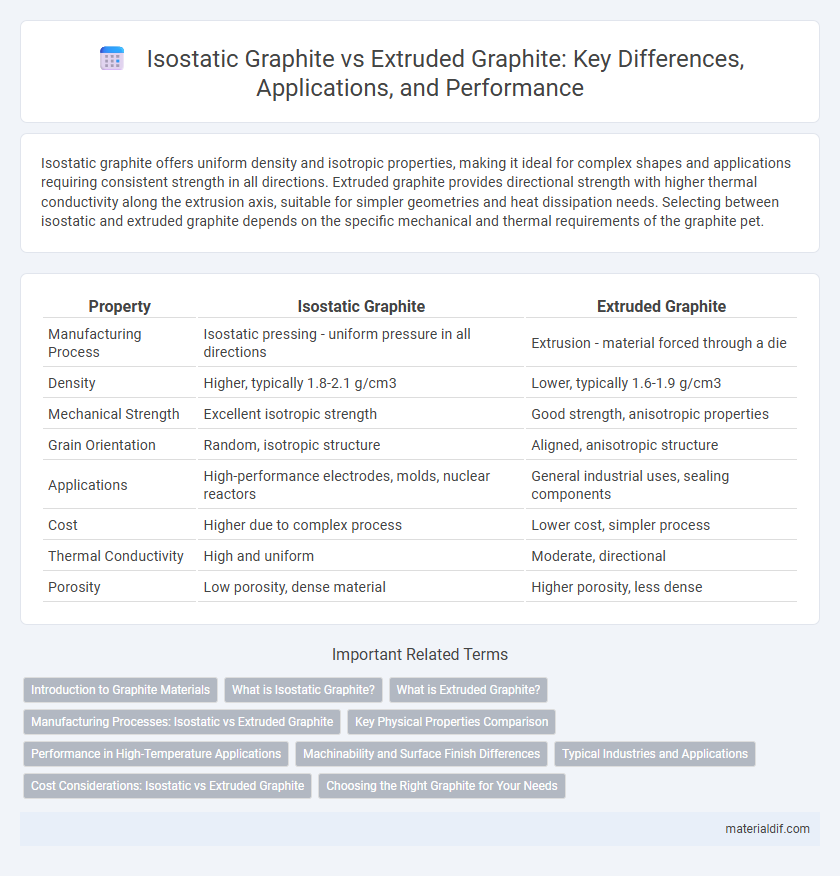

| Property | Isostatic Graphite | Extruded Graphite |

|---|---|---|

| Manufacturing Process | Isostatic pressing - uniform pressure in all directions | Extrusion - material forced through a die |

| Density | Higher, typically 1.8-2.1 g/cm3 | Lower, typically 1.6-1.9 g/cm3 |

| Mechanical Strength | Excellent isotropic strength | Good strength, anisotropic properties |

| Grain Orientation | Random, isotropic structure | Aligned, anisotropic structure |

| Applications | High-performance electrodes, molds, nuclear reactors | General industrial uses, sealing components |

| Cost | Higher due to complex process | Lower cost, simpler process |

| Thermal Conductivity | High and uniform | Moderate, directional |

| Porosity | Low porosity, dense material | Higher porosity, less dense |

Introduction to Graphite Materials

Isostatic graphite and extruded graphite are two primary forms of synthetic graphite materials distinguished by their manufacturing processes and structural properties. Isostatic graphite is produced through a powder metallurgy process that applies uniform pressure in all directions, resulting in a highly isotropic microstructure with superior mechanical strength and thermal conductivity. Extruded graphite is made by forcing a mixture of graphite powder and binder through a die, creating a directional grain structure that offers excellent machinability but lower strength and thermal performance compared to isostatic graphite.

What is Isostatic Graphite?

Isostatic graphite is a highly uniform and isotropic form of graphite produced by pressing graphite powder in all directions using isostatic pressing technology. This method results in a dense, fine-grained structure with excellent mechanical strength, thermal conductivity, and resistance to thermal shock. It is widely used in applications requiring high purity and structural integrity, such as aerospace, semiconductor manufacturing, and high-temperature industrial processes.

What is Extruded Graphite?

Extruded graphite is a form of synthetic graphite produced by mixing graphite particles with a binder and then forcing the mixture through a shaped die to create a continuous, uniform structure. This process results in a highly dense, anisotropic material with excellent mechanical strength and thermal conductivity, ideal for applications requiring precise machining and structural stability. Extruded graphite is commonly used in electrodes for electric arc furnaces, mechanical seals, and high-temperature industrial components.

Manufacturing Processes: Isostatic vs Extruded Graphite

Isostatic graphite is manufactured using a powder compression process that applies uniform pressure in all directions, resulting in a highly dense and isotropic material with superior strength and thermal conductivity. Extruded graphite is produced by forcing a graphite paste through a die, creating anisotropic properties with aligned grain structure that provides enhanced machinability but lower uniformity in mechanical properties. The isostatic process offers better homogeneity and performance in high-stress applications, while extruded graphite is preferred for components requiring precise shaping and lower production costs.

Key Physical Properties Comparison

Isostatic graphite exhibits uniform density, high strength, and isotropic thermal conductivity, making it ideal for applications requiring consistent performance under thermal and mechanical stress. Extruded graphite has anisotropic properties with higher strength and thermal conductivity along the extrusion direction but lower values perpendicular to it, suitable for shapes requiring directional strength. Key physical properties such as bulk density (1.75-1.85 g/cm3 for isostatic vs. 1.65-1.80 g/cm3 for extruded) and flexural strength (35-50 MPa for isostatic vs. 30-45 MPa for extruded) highlight the material selection criteria based on application-specific mechanical and thermal demands.

Performance in High-Temperature Applications

Isostatic graphite offers superior uniformity and isotropic mechanical properties, making it ideal for high-temperature applications requiring consistent strength and thermal conductivity. Extruded graphite, while cost-effective and exhibiting good directional strength, may have anisotropic properties that limit performance under extreme thermal stress. For applications such as furnace components and aerospace parts operating above 2000degC, isostatic graphite ensures enhanced thermal shock resistance and structural integrity.

Machinability and Surface Finish Differences

Isostatic graphite offers superior machinability compared to extruded graphite due to its isotropic grain structure, which allows for uniform cutting and reduced tool wear. The homogeneous nature of isostatic graphite results in a smoother, more consistent surface finish, making it ideal for precision applications. Extruded graphite, with its anisotropic grain alignment, tends to produce uneven surfaces and requires more frequent tool adjustments during machining.

Typical Industries and Applications

Isostatic graphite is favored in aerospace, semiconductor, and nuclear industries for components like crucibles, electrodes, and heat shields due to its isotropic properties and high purity. Extruded graphite finds typical applications in metallurgy, automotive, and chemical processing industries, particularly in furnace linings, molds, and battery anodes, benefiting from its directional strength and machinability. Both types support high-temperature and corrosive environments, with isostatic graphite excelling in precision and durability, while extruded graphite offers cost-effective production for large-scale applications.

Cost Considerations: Isostatic vs Extruded Graphite

Isostatic graphite typically incurs higher production costs due to its uniform density and isotropic properties achieved through powder blending and pressing from multiple directions. Extruded graphite offers lower costs by utilizing unidirectional extrusion, resulting in less material and energy consumption but with anisotropic mechanical characteristics. Cost considerations must balance the price difference against application requirements for mechanical strength, thermal conductivity, and machinability.

Choosing the Right Graphite for Your Needs

Isostatic graphite offers uniform density and isotropic properties, making it ideal for complex shapes and high-stress applications requiring consistent thermal conductivity and mechanical strength. Extruded graphite provides directional strength and is cost-effective for simpler geometries, with superior machinability and electrical conductivity along the extrusion axis. Selecting between isostatic and extruded graphite depends on the specific application demands, such as structural integrity, thermal performance, and manufacturing precision.

Isostatic Graphite vs Extruded Graphite Infographic

materialdif.com

materialdif.com