Graphite anodes and graphite cathodes play distinct roles in battery technology, with graphite anodes primarily facilitating lithium-ion intercalation, enhancing energy storage capacity and charge efficiency. Graphite cathodes, less commonly used, serve as conductive agents or structural supports in various battery designs, contributing to overall stability and performance. The choice between graphite anode and cathode materials significantly impacts battery life, charge speed, and energy density in applications like electric vehicles and portable electronics.

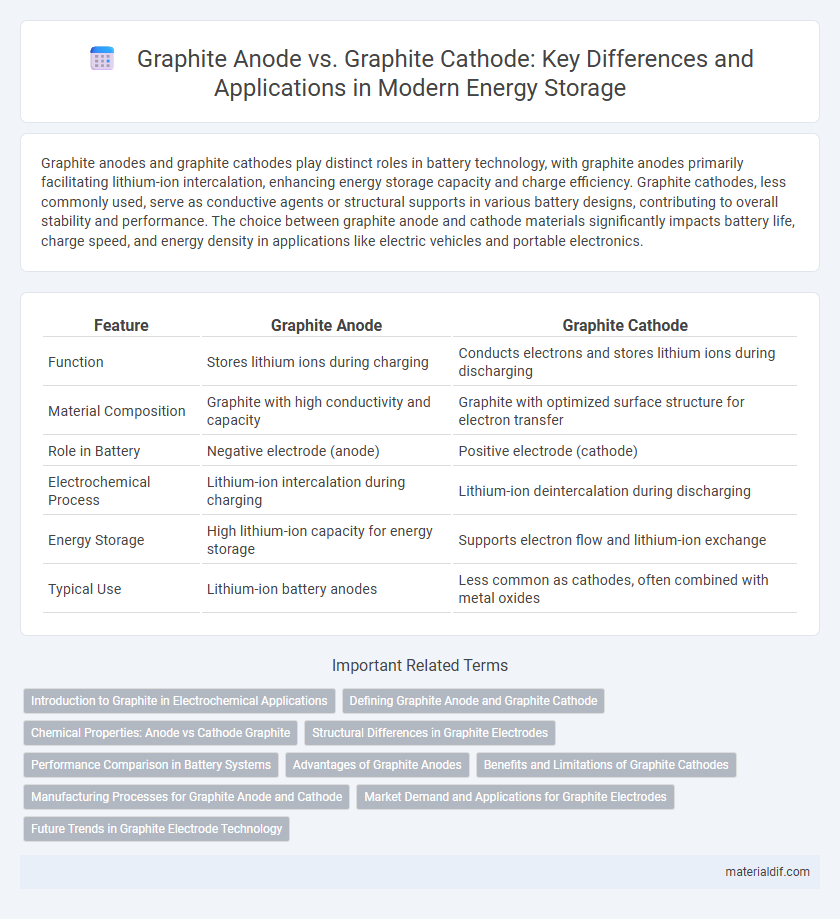

Table of Comparison

| Feature | Graphite Anode | Graphite Cathode |

|---|---|---|

| Function | Stores lithium ions during charging | Conducts electrons and stores lithium ions during discharging |

| Material Composition | Graphite with high conductivity and capacity | Graphite with optimized surface structure for electron transfer |

| Role in Battery | Negative electrode (anode) | Positive electrode (cathode) |

| Electrochemical Process | Lithium-ion intercalation during charging | Lithium-ion deintercalation during discharging |

| Energy Storage | High lithium-ion capacity for energy storage | Supports electron flow and lithium-ion exchange |

| Typical Use | Lithium-ion battery anodes | Less common as cathodes, often combined with metal oxides |

Introduction to Graphite in Electrochemical Applications

Graphite serves as a crucial material in electrochemical applications due to its excellent electrical conductivity, chemical stability, and layered structure that facilitate ion intercalation. In lithium-ion batteries, graphite anodes enable efficient lithium ion storage through reversible intercalation, providing high capacity and long cycle life. Conversely, graphite cathodes are less common but used in certain systems for their stability and ability to act as conductive matrices, highlighting graphite's versatile role across electrochemical devices.

Defining Graphite Anode and Graphite Cathode

Graphite anodes are the negative electrodes in batteries, primarily used in lithium-ion batteries to facilitate lithium-ion intercalation during charging. Graphite cathodes, though less common, refer to the positive electrodes where lithium ions de-intercalate during discharge in specific battery chemistries. Understanding the electrochemical roles of graphite anodes and cathodes is crucial for optimizing battery performance and longevity.

Chemical Properties: Anode vs Cathode Graphite

Graphite anodes exhibit higher reactivity and lithium intercalation capacity due to their layered structure facilitating electron donation, making them ideal for battery oxidation reactions. Graphite cathodes display greater structural stability and resistance to reduction, with tightly bonded carbon atoms favoring electron acceptance during electrochemical processes. Differences in chemical properties such as electron affinity and oxidation state significantly influence their roles in energy storage and conversion systems.

Structural Differences in Graphite Electrodes

Graphite anodes typically feature a layered structure with higher porosity to facilitate lithium-ion intercalation during charging cycles, enhancing ion diffusion and storage capacity. In contrast, graphite cathodes exhibit a denser, more compact structure optimized for electron conduction and structural stability under oxidative conditions. These structural differences between graphite anode and cathode materials directly influence their electrochemical performance and longevity in lithium-ion batteries.

Performance Comparison in Battery Systems

Graphite anodes exhibit high lithium-ion intercalation capacity, enabling excellent charge retention and cycle stability in lithium-ion batteries, while graphite cathodes face limitations due to lower electrochemical potential and structural degradation under high voltage. Performance comparison reveals that graphite anodes deliver superior conductivity and faster lithium diffusion rates, optimizing energy density and power output in battery systems. Variations in crystallographic structure and surface area critically influence the anode's efficiency, making graphite anodes the preferred choice for enhanced battery longevity and fast-charging capabilities.

Advantages of Graphite Anodes

Graphite anodes offer superior lithium-ion intercalation capacity, enhancing battery charge efficiency and lifespan compared to graphite cathodes. Their high electrical conductivity and structural stability reduce degradation during cycling, leading to improved overall battery performance. This makes graphite anodes an essential component in high-energy-density lithium-ion batteries used in electric vehicles and portable electronics.

Benefits and Limitations of Graphite Cathodes

Graphite cathodes in lithium-ion batteries offer high electrical conductivity and chemical stability, enhancing battery efficiency and lifespan. Their benefits include improved charge retention and resistance to degradation during cycling, contributing to overall battery durability. Limitations involve susceptibility to lithium plating at high charge rates, which can reduce performance and safety, requiring careful management in battery design.

Manufacturing Processes for Graphite Anode and Cathode

Graphite anode manufacturing involves processes such as petroleum coke calcination, blending with additives, molding, baking, and graphitization at high temperatures exceeding 2500degC to enhance conductivity and structural integrity. Graphite cathode production includes extrusion or molding of petroleum coke and coal tar pitch, followed by baking, impregnation with pitch for improved density, and a final graphitization process typically conducted at temperatures around 2800degC. Both anode and cathode fabrication prioritize precise control of porosity, grain size, and electrical properties to meet stringent performance requirements in electrochemical applications.

Market Demand and Applications for Graphite Electrodes

Graphite anodes exhibit growing demand in lithium-ion battery production for electric vehicles and portable electronics due to their high conductivity and stability. Graphite cathodes, primarily used in industrial furnaces and steel manufacturing, face steady market demand driven by their ability to withstand high temperatures and corrosive environments. The graphite electrode market dynamics are influenced by advancements in energy storage technologies and the steel industry's expansion, with anodes leading growth in the battery sector and cathodes maintaining importance in metallurgical processes.

Future Trends in Graphite Electrode Technology

Graphite anode and cathode materials are evolving rapidly with innovations targeting higher energy density and enhanced cycle life in lithium-ion batteries. Future trends in graphite electrode technology emphasize the development of nano-structured graphite and hybrid composites to improve electrical conductivity and structural stability. Advancements in sustainable production methods and recycling techniques are also driving the shift towards eco-friendly, cost-effective graphite electrodes.

Graphite Anode vs Graphite Cathode Infographic

materialdif.com

materialdif.com